Method for operating workstation of spinning machine and workstation

A technology for workstations and spinning machines, applied to spinning machines, free-end spinning machines, continuous winding spinning machines, etc., can solve problems such as large waste yarns

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

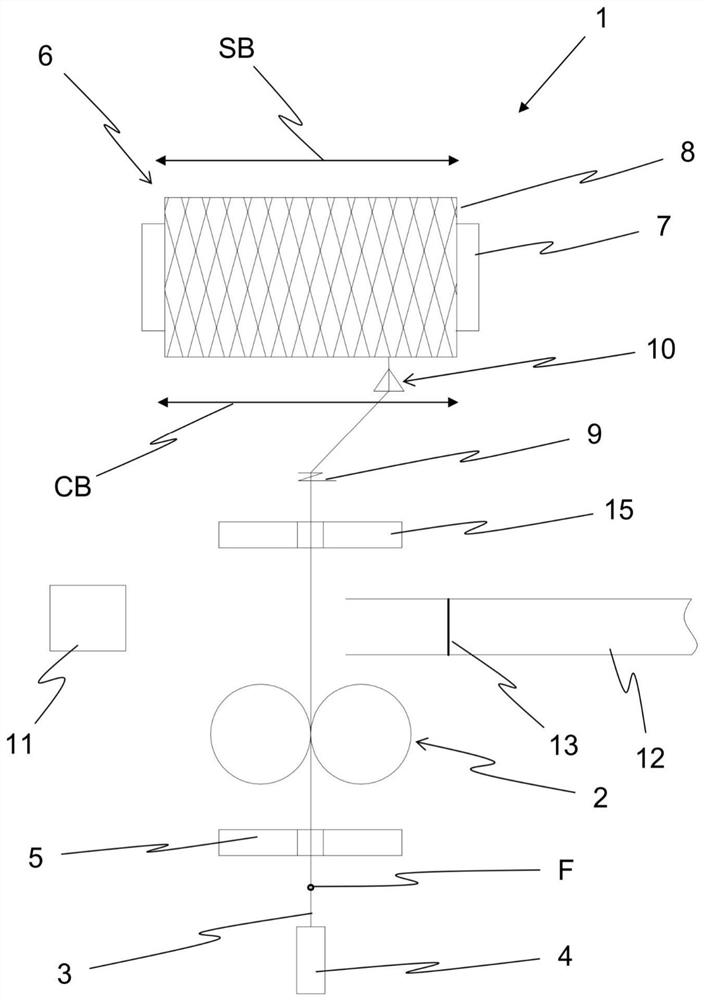

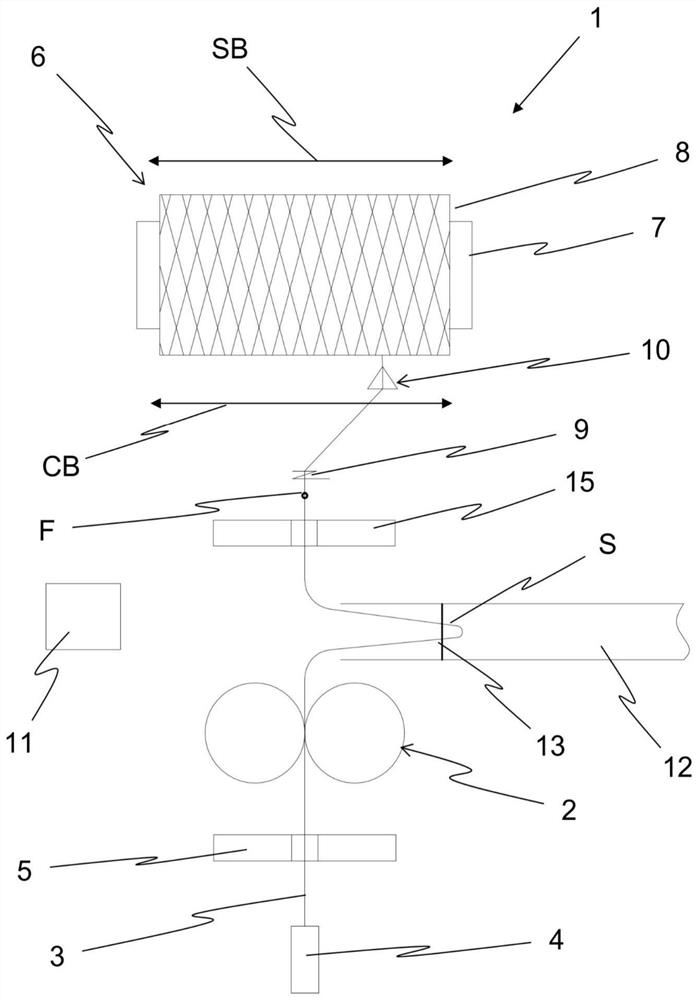

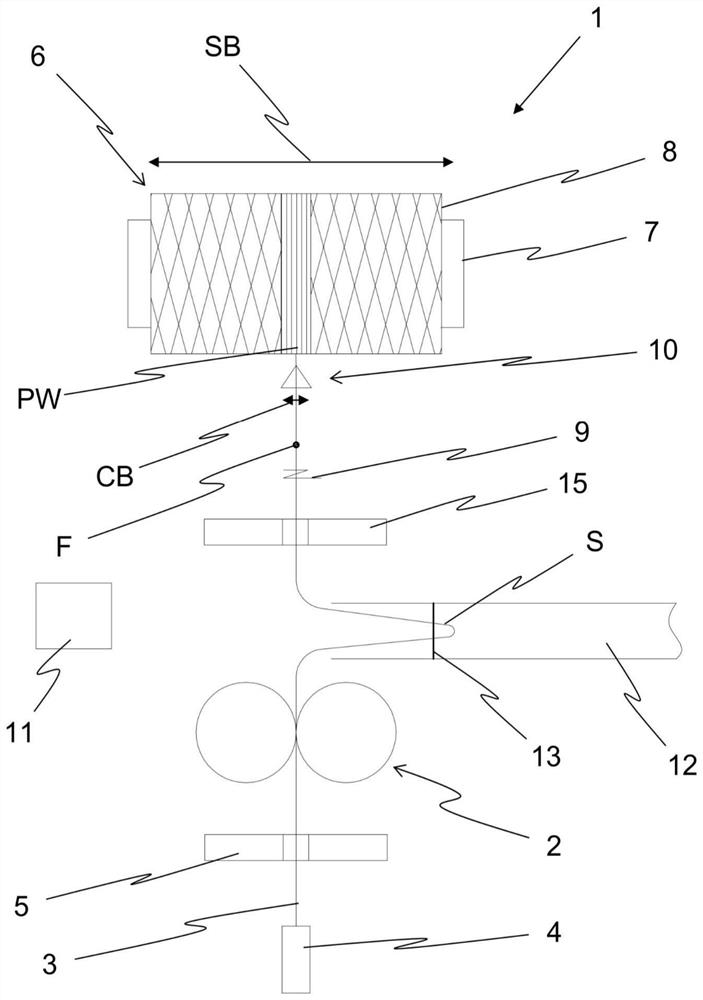

[0024] figure 1 A schematic frontal detail view of the workstation 1 of the spinning machine during normal operation is shown. During normal operation, the yarn 3 is drawn from the spinning unit 4 by the yarn drawing device 2 at the yarn drawing speed. The yarn drawing device 2 is preferably constructed in the form of a pair of drawing rollers. In the embodiment shown, the spinning unit 4 is a spinneret of an air-jet spinning machine with a vortex chamber, in which the filaments of the fiber material are twisted into the yarn 3 by means of a vortex of air. This figure does not show the feeding of the fiber material, which is generally achieved by a drafting system in an air-jet spinning machine.

[0025] Alternatively, if the work station 1 is the work station 1 of a rotor spinning machine, a fiber opening device is generally used to open the fiber material into its individual filaments. Instead of a vortex chamber, the spinning unit 4 has a rapidly rotating rotor to form ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com