Vibration-damper for steel sheet

A vibration damping device and steel plate technology, which is applied in the field of steel plate vibration damping devices, can solve the problems of electromagnet and steel plate contact, vibration increase, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

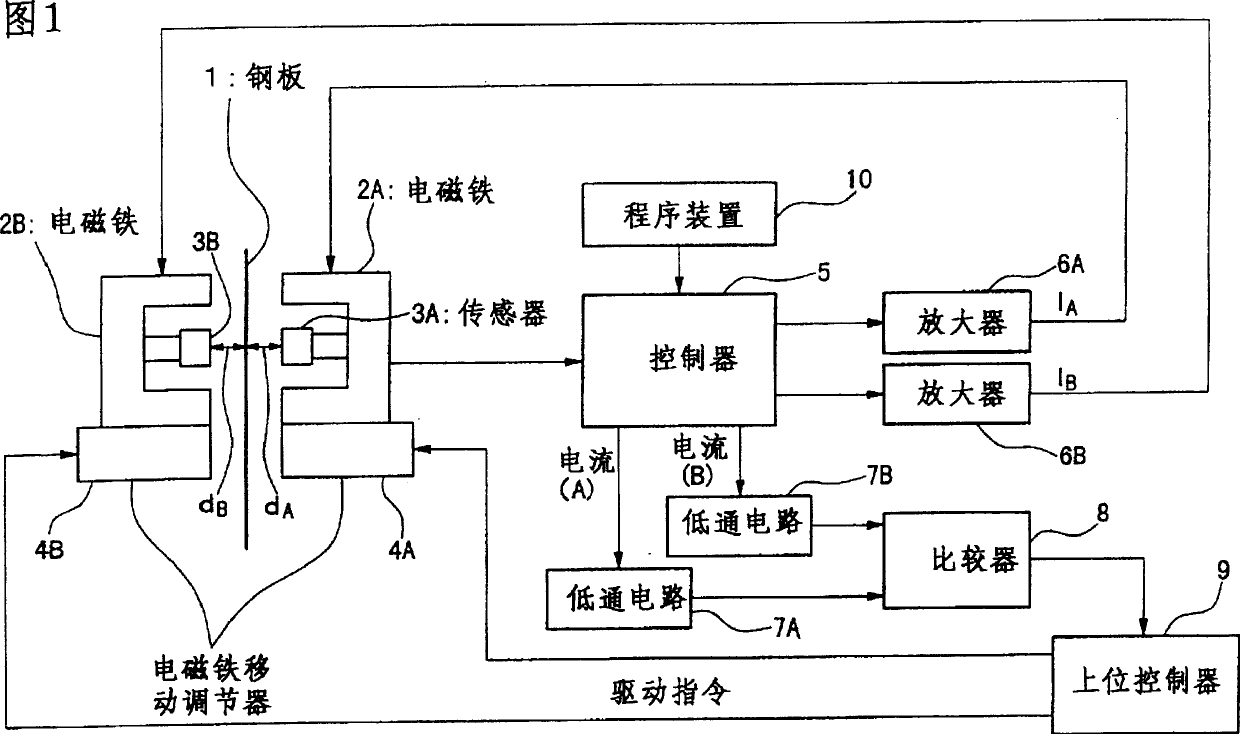

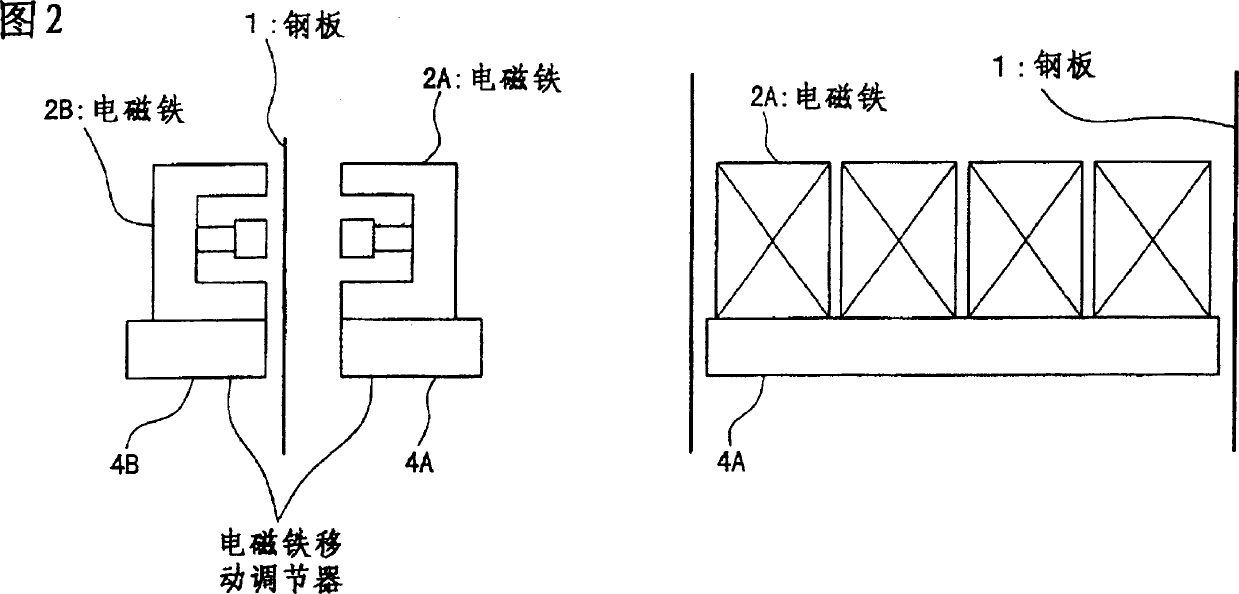

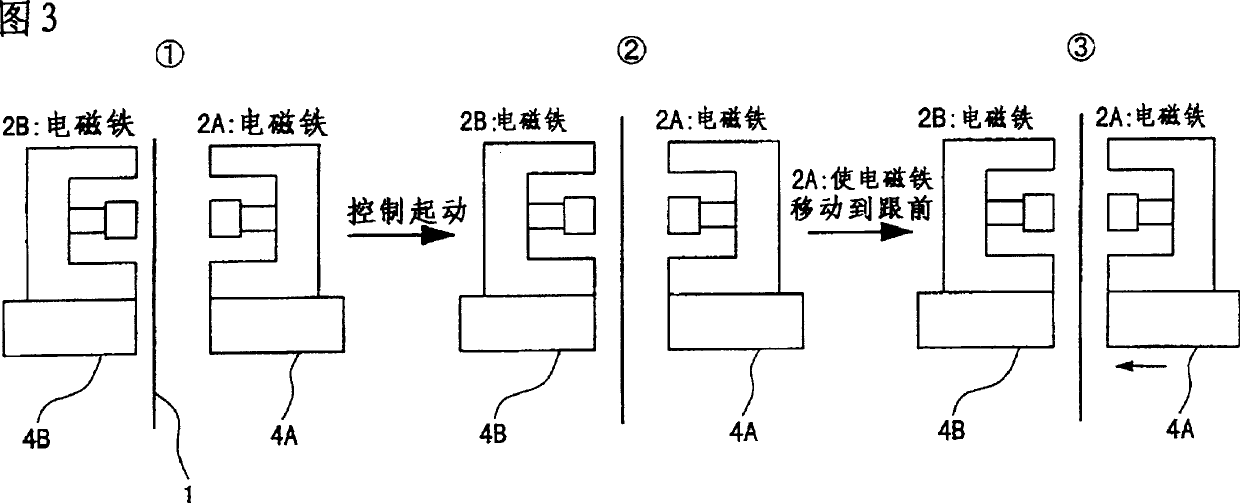

[0050]The configuration of Embodiment 1 of the present invention is shown in FIG. 1 . The steel plate 1 moves from the bottom to the top in the figure. In this figure, a picture of the steel plate 1 viewed from the side is shown. An electromagnet 2A is provided on the front side of the moving steel plate 1, and an electromagnet 2B is provided on the back side. The electromagnets 2A and 2B are installed at positions opposing to each other across the steel plate 1 . In the electromagnet 2A, a sensor 3A for detecting the distance from the electromagnet to the steel plate 1 is provided, and in the electromagnet 2B, a sensor 3B for detecting the distance is also provided. The detection surface of the sensor 3A is on the same surface as the magnetic pole surface of the electromagnet 2A, and the detection surface of the sensor 3B is on the same surface as the magnetic pole surface of the electromagnet 2B. Both the sensors 3A and 3B are installed at positions facing each other acro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com