Die regulating method for preventing crack in punched large covering vehicle body part

An adjustment method and large-scale technology, applied in the field of mold manufacturing, can solve problems such as mold scrapping, drawing cracking, economic loss, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

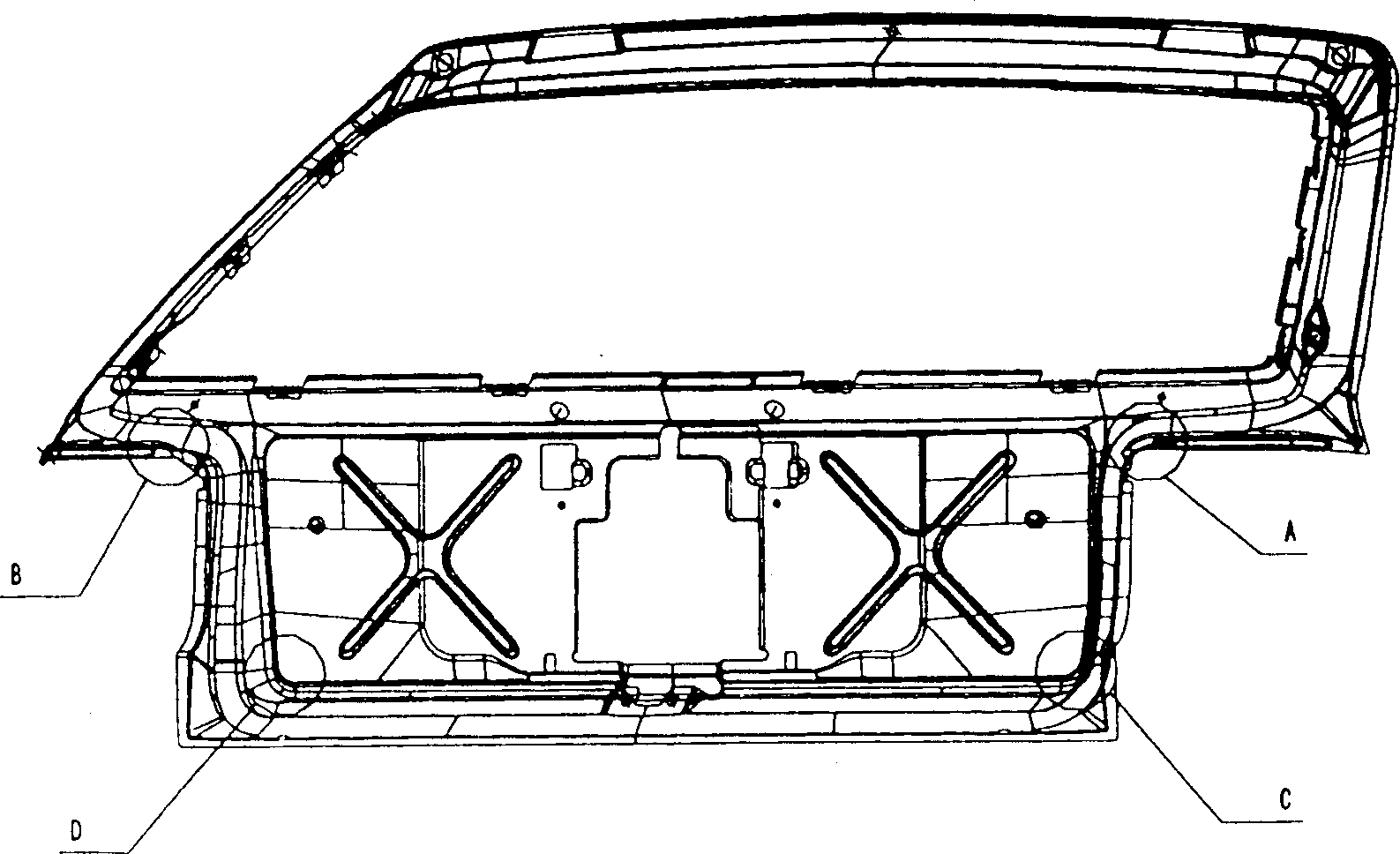

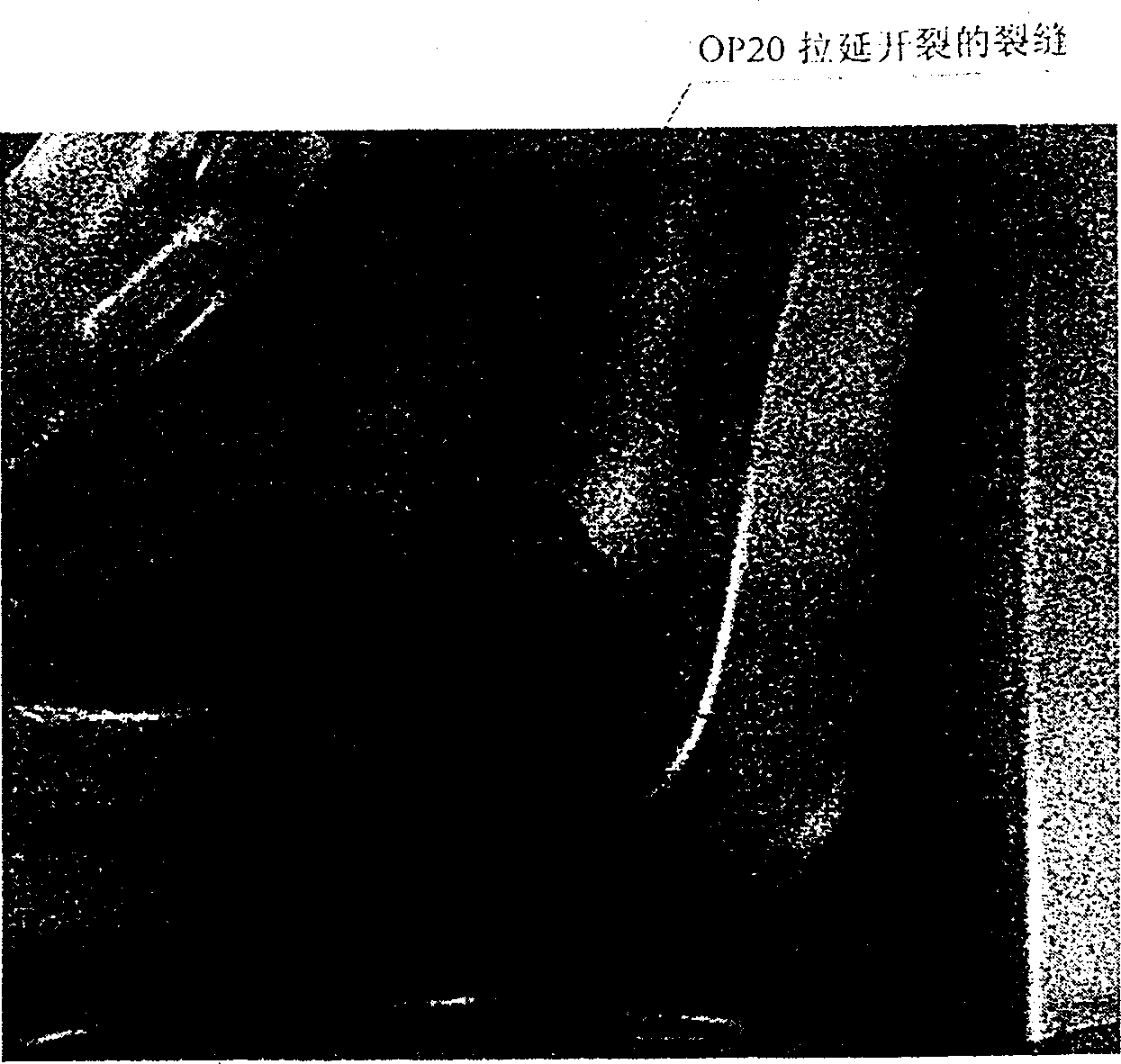

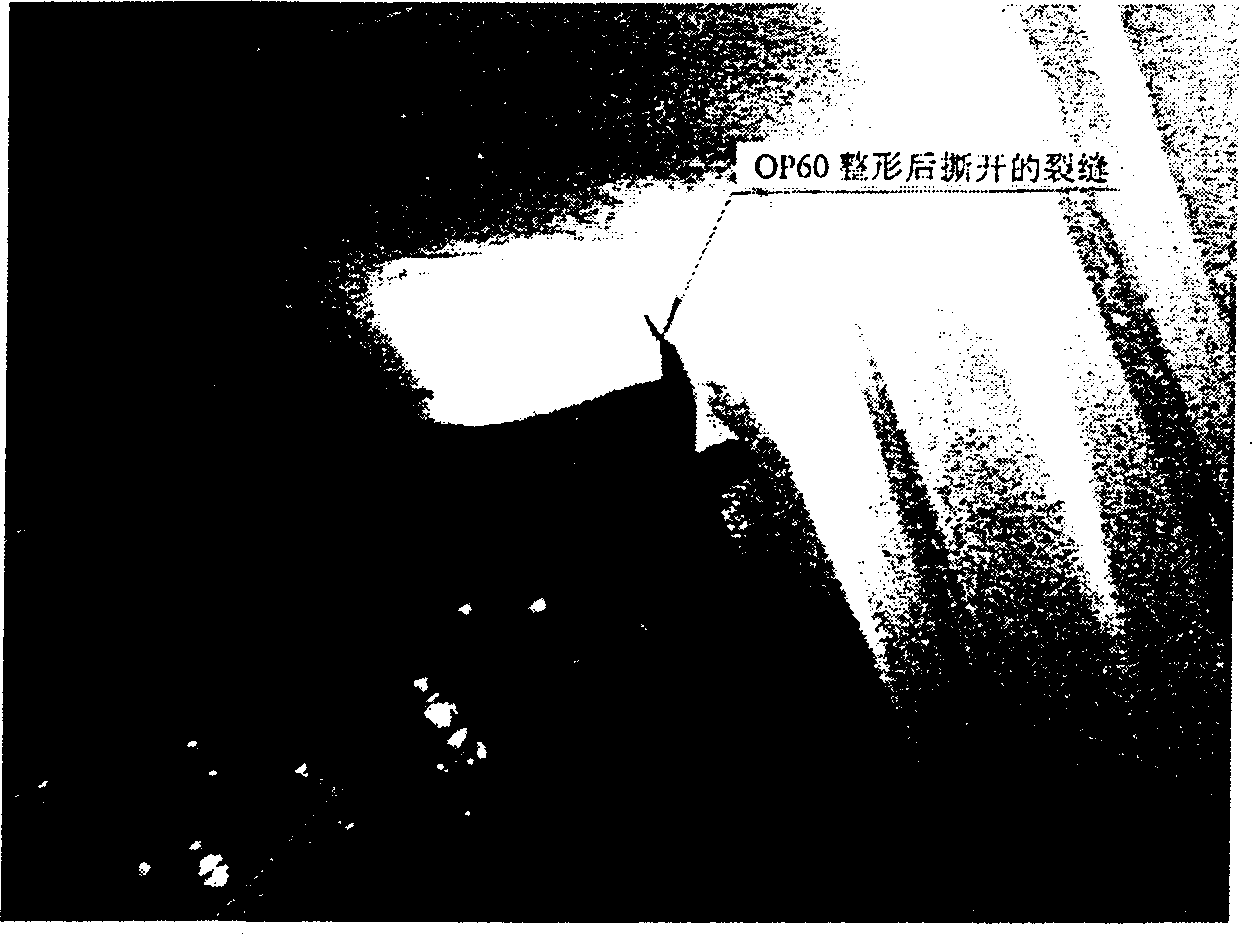

[0021] According to the mold manufacturing technology of the present invention, at first the convex hull on the OP20 drawing die is tested. Utilizing the perfect technology of foreign die manufacturers, a polyester compound material is used to modify the convex hull, and the height of the left convex hull is increased from 50mm to 60mm. Through the test punching, the test was successful once, and the drawn part was changed from a 50mm high convex hull to a 60mm high convex hull without cracking. At that time, the method of manual trimming was used to complete the OP60 shaping process. As a result, the final part that did not crack and did not need to be opened was pressed out, and the problem of shaping and tearing was also solved (see Figure 10 ). The mold manufacturing technology of the present invention has been verified here, and is indeed feasible.

[0022] According to the four technologies of the mold manufacturing technology of the present invention, foreign die man...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com