Combined transmission mechanism with replaceable single tooth

A transmission mechanism and combined technology, applied to components with teeth, mechanical equipment, portable lifting devices, etc., can solve problems affecting production, easy to wear, etc., and achieve the effects of cost saving, easy manufacturability, and easy replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

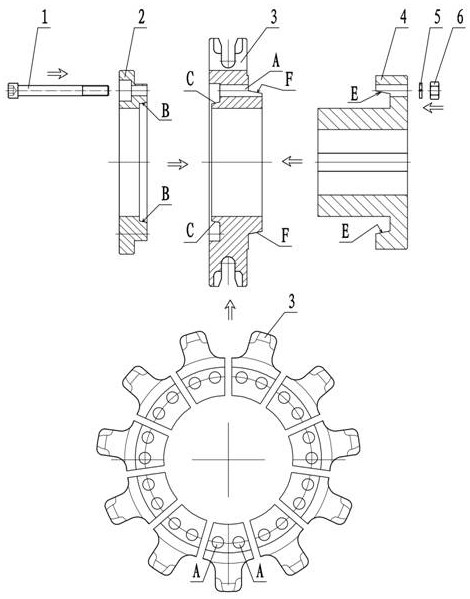

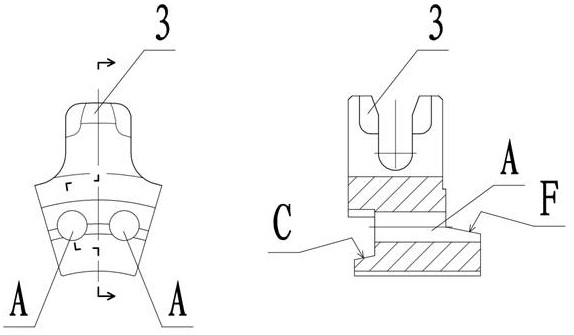

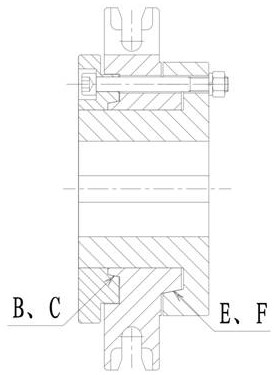

[0013] like figure 1 , 2 As shown, based on the base 4, a plurality of single transmission teeth 3 are combined on the outer periphery of the base 4, and inserted into the positioning groove of the base 4 (the positioning groove and the cone surface of the E base are in the same area), through the gland 2 Gather a number of single transmission teeth 3 and the base 4 together, and insert the flange of the gland 2 into the positioning groove of the single transmission tooth 3 (the positioning groove is in the same area as the conical surface of the single transmission tooth of C) to ensure that the single transmission tooth 3 Align the through hole A of the gland with the through hole on the gland 2 and the base 4, and then fasten it with the screw 1, elastic washer 5, and nut 6 to make the whole fit together tightly; such as image 3 The effect diagram after assembly.

[0014] When disassembling, loosen the nut 6, remove the nut 6 and the elastic washer 5, and use the necessa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com