High-sealing bearing for industrial dust collector motor

An industrial vacuum cleaner and high-sealing technology, applied in the directions of shafts and bearings, bearing cooling, bearing components, etc., can solve problems such as insufficient sealing effect, improve dustproof effect, avoid complex structure, and facilitate connection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

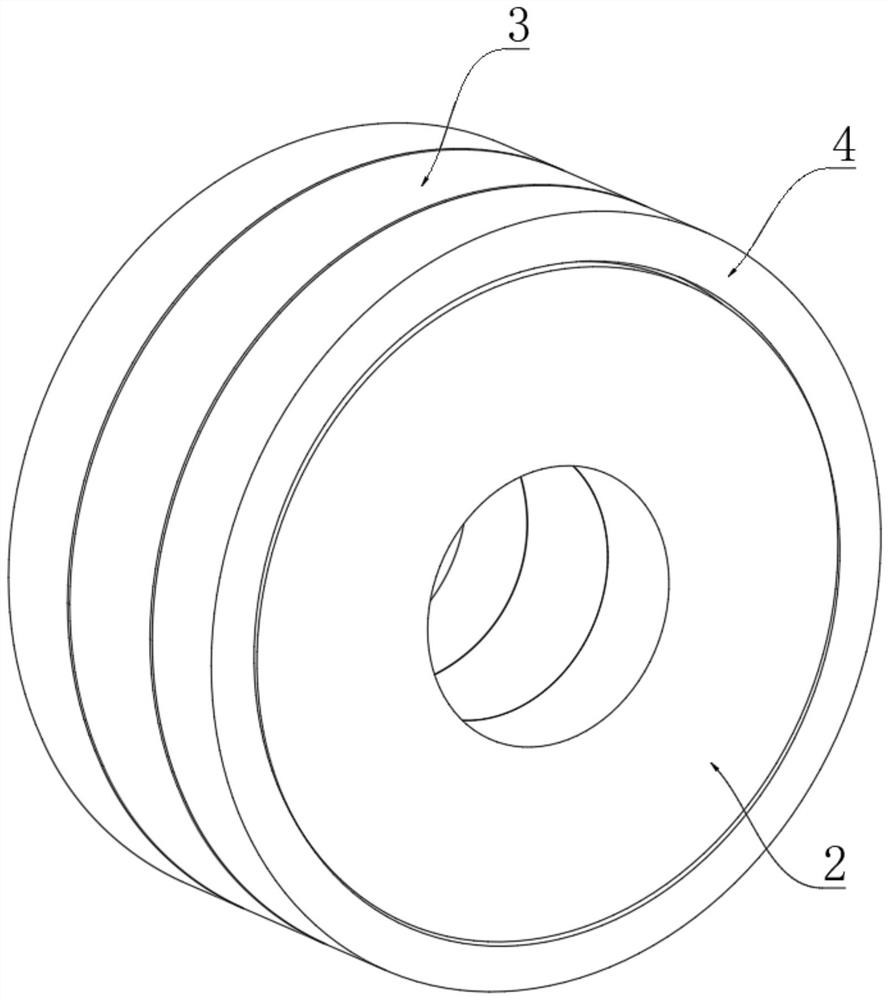

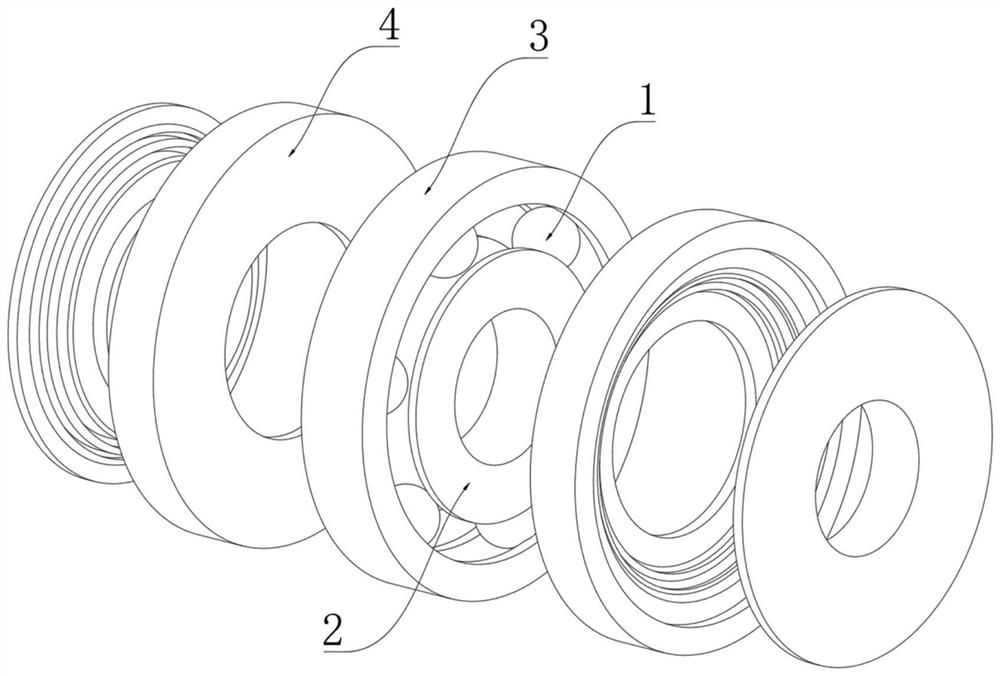

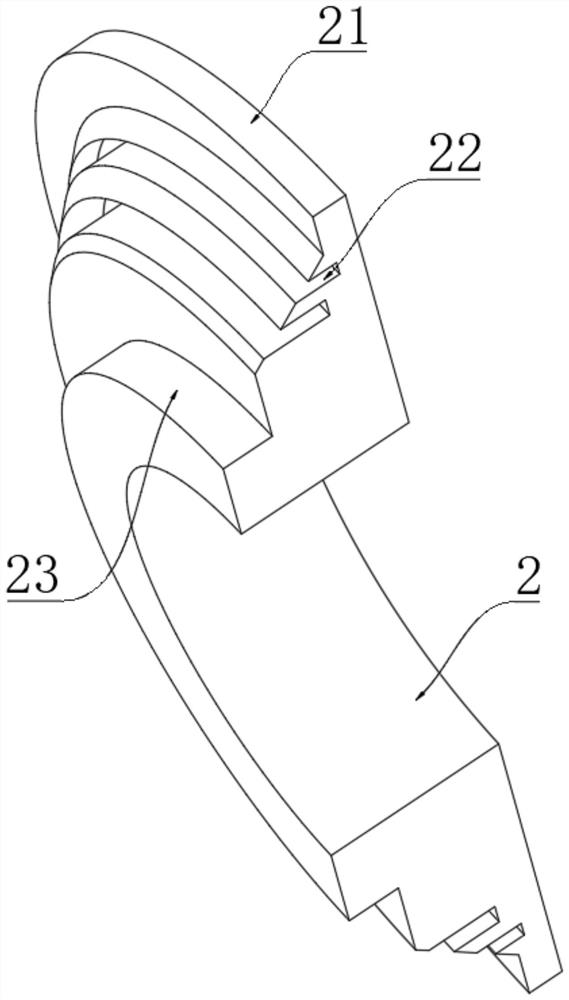

[0049] as attached Figure 1-5 and Figure 13-16 The shown high-sealing bearing for an industrial vacuum cleaner motor includes a bearing body, the bearing body includes an inner ring body 2 and an outer ring body 3, a raceway is formed between the inner ring body 2 and the outer ring body 3, and balls are assembled inside the raceway. 1. Add a sealing ring body 4 on both sides of the outer ring body 3, and the sealing ring body 4 contacts the inner ring body 2 to form a sealing part to realize the sealing effect. The inner ring body 2, the outer ring body 3 and the sealing ring body 4 A number of pin holes 12 are opened, and pins 13 are embedded and installed in the pin holes 12. The pins 13 are inserted into the pin holes 12 for assembly, so that the inner ring body 2, the outer ring body 3 and the sealing ring body 4 are formed into a whole, and the outer ring body 2 is assembled. Both the ring body 3 and the sealing ring body 4 are composed of a set of symmetrically arran...

Embodiment 2

[0056] Refer to the manual attached Figure 6-16 The shown high-sealing bearing for an industrial vacuum cleaner motor includes a bearing body, the bearing body includes an inner ring body 2 and an outer ring body 3, a raceway is formed between the inner ring body 2 and the outer ring body 3, and balls are assembled inside the raceway. 1. Add a sealing ring body 4 on both sides of the outer ring body 3, and the sealing ring body 4 contacts the inner ring body 2 to form a sealing part to realize the sealing effect. The inner ring body 2, the outer ring body 3 and the sealing ring body 4 A number of pin holes 12 are opened, and pins 13 are embedded and installed in the pin holes 12. The pins 13 are inserted into the pin holes 12 for assembly, so that the inner ring body 2, the outer ring body 3 and the sealing ring body 4 are formed into a whole, and the outer ring body 2 is assembled. Both the ring body 3 and the sealing ring body 4 are composed of a set of symmetrically arrang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com