Crushing equipment for silver-lead concentrate

A crushing equipment and lead concentrate technology, applied in the field of silver-lead concentrate crushing equipment, can solve problems such as energy waste, affecting the health of relevant personnel, and dust at the operation site, and achieve the effect of ensuring the crushing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

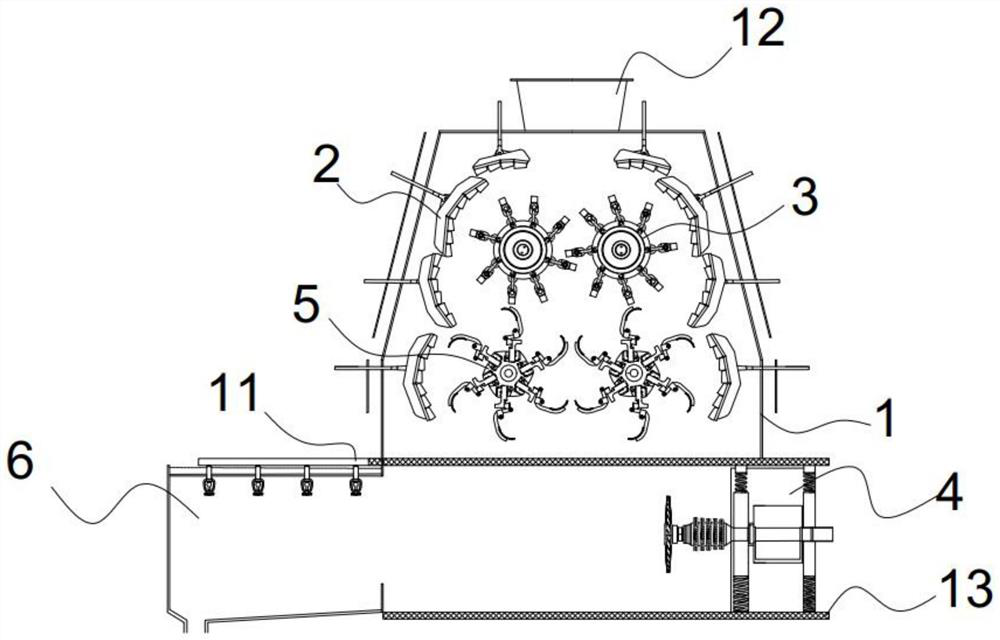

[0049] see Figures 1 to 6 , in the embodiment of the present invention, a kind of crushing equipment for silver-lead concentrate, comprising:

[0050] rack 1;

[0051] Breaking hammers 3, two of which are rotatably arranged inside the frame 1;

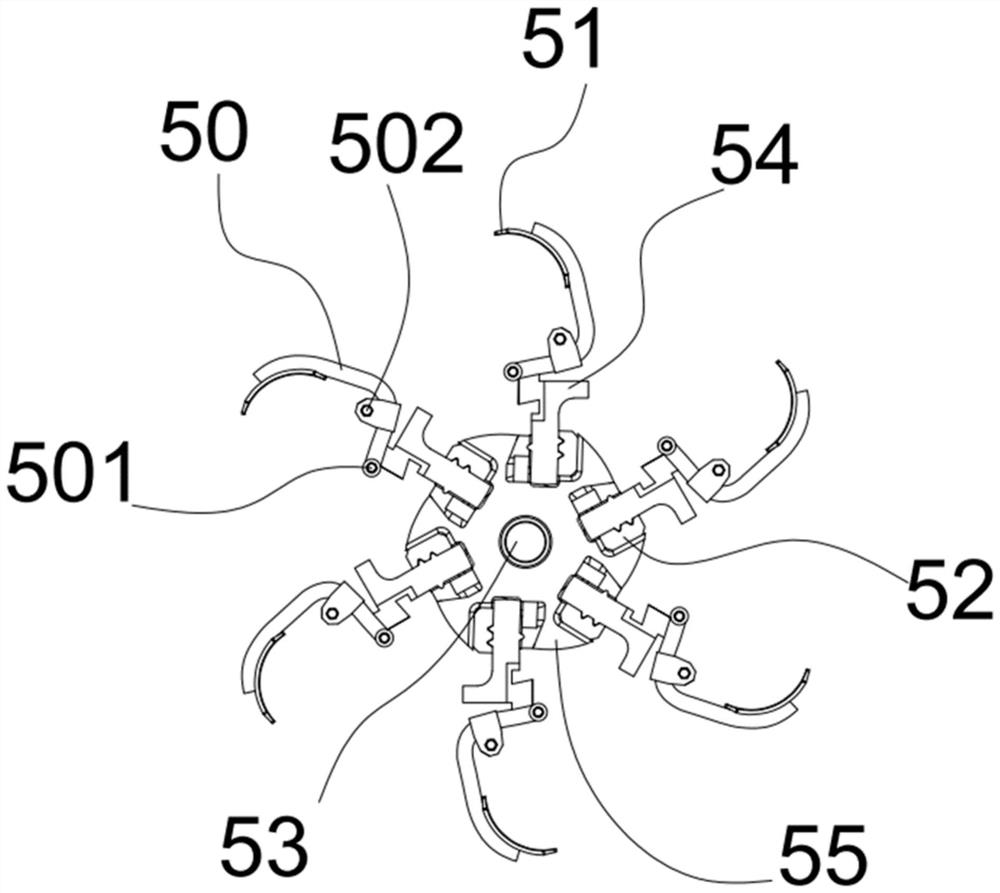

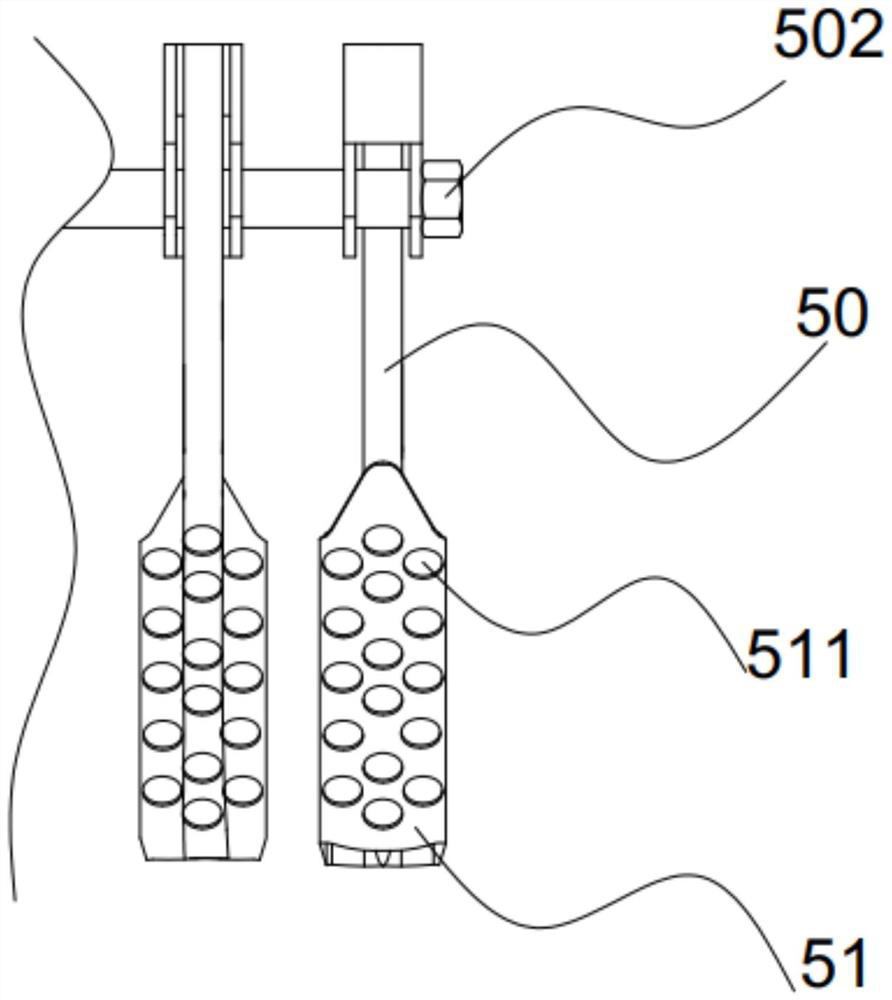

[0052] Filter return hammers 5, two of the filter return hammers 5 are respectively rotatably arranged inside the frame 1 and are respectively located directly below the two breakers 3;

[0053] The side counterattack plate 2 is adjustable on both sides of the breaker 3 and the breaker return hammer 5, wrapping the breaker hammer 3 and the breaker return hammer 5;

[0054] The vibrating dust removal fan 4 is arranged below the crushing return hammer 5, and is located at the lower part of the frame 1;

[0055] The dust removal bin 6 is connected to the side of the lower part of the frame 1 away from the vibration dust removal fan 4;

[0056] In this embodiment, as figure 1 , the rack 1 includes:

[0057] It is used to install the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com