Double-sided steam cleaning mop

A cleaning and steam technology, applied in the direction of carpet cleaning, floor cleaning, cleaning equipment, etc., can solve the problem of low steam utilization rate, achieve the effect of high steam utilization rate, avoid steam loss, and facilitate switching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The specific embodiments of the present invention will be described in further detail below with reference to the accompanying drawings and embodiments. The following examples are intended to illustrate the present invention, but not to limit the scope of the present invention.

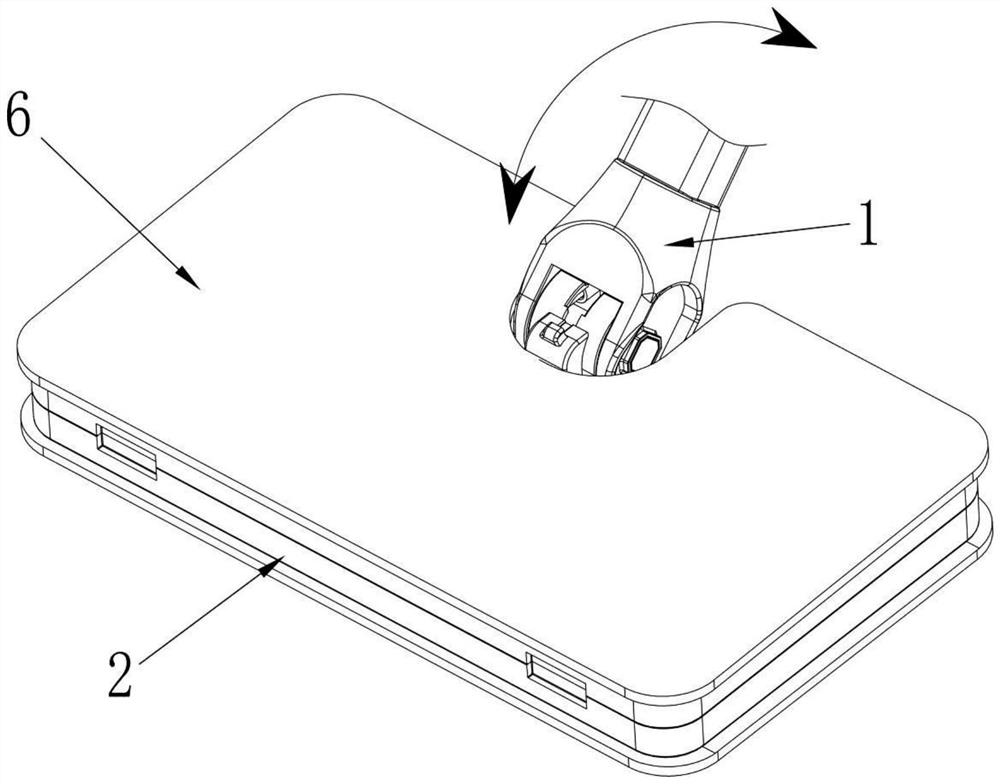

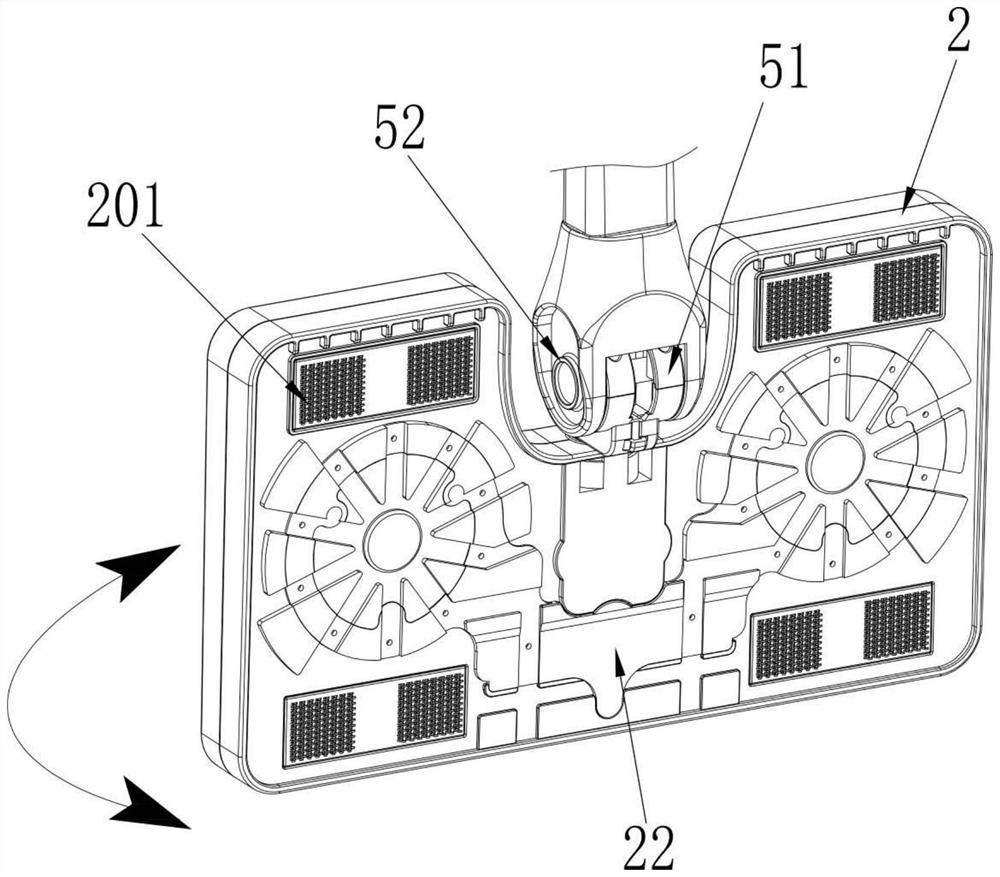

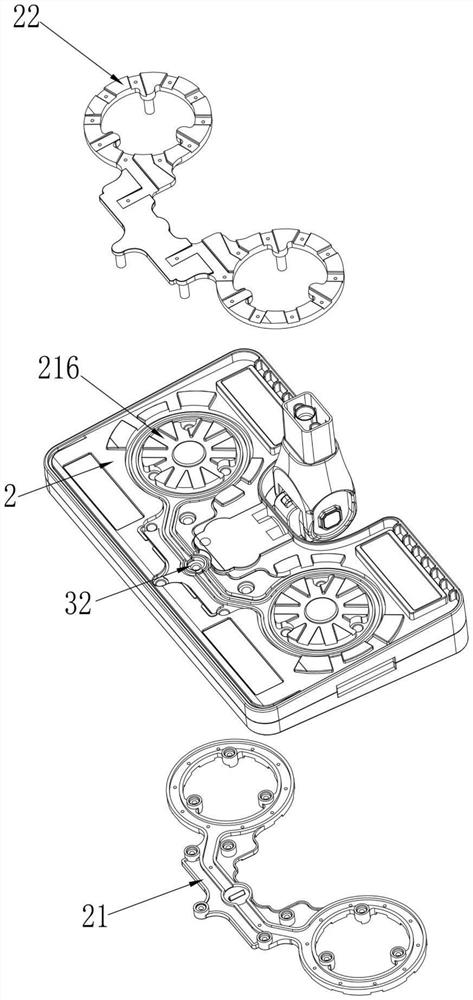

[0037] see Figure 1 to Figure 12 , The present invention provides a double-sided steam cleaning mop, comprising a mop main body 1 , a mop head 2 , a steam nozzle assembly 3 and a reversing device 4 .

[0038] see figure 1 , the main body 1 of the floor mop is provided with a steam generating device (not shown in the figure), and the steam generating device can generate steam and guide the steam to the floor mopping head 2 .

[0039] see figure 2 and image 3 , the mop head 2 can be rotated 360 degrees and installed on the lower end of the mop main body 1 . Using the 360-degree rotating ground tractor 2, it is not necessary to consider the forward and reverse rotation when switching the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com