Manufacturing method of copper-embedded circuit board

A production method and circuit board technology, applied in the direction of multi-layer circuit manufacturing, etc., can solve the problems of slow operation, easy leakage or displacement, and easy error, and achieve the effect of accurate embedding position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The technical solutions of the present invention will be described in detail below with reference to the drawings.

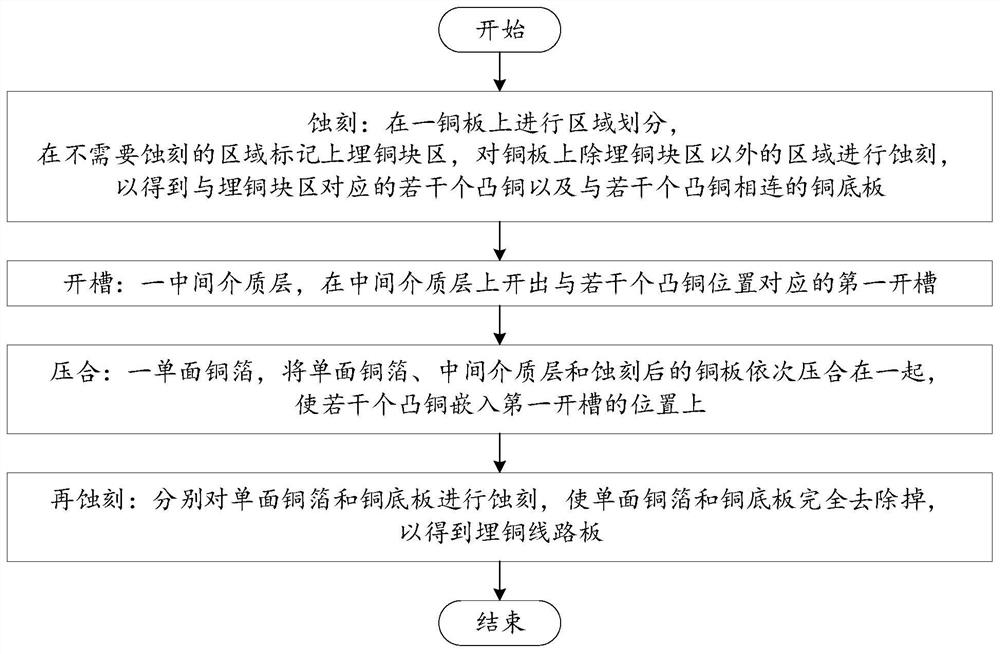

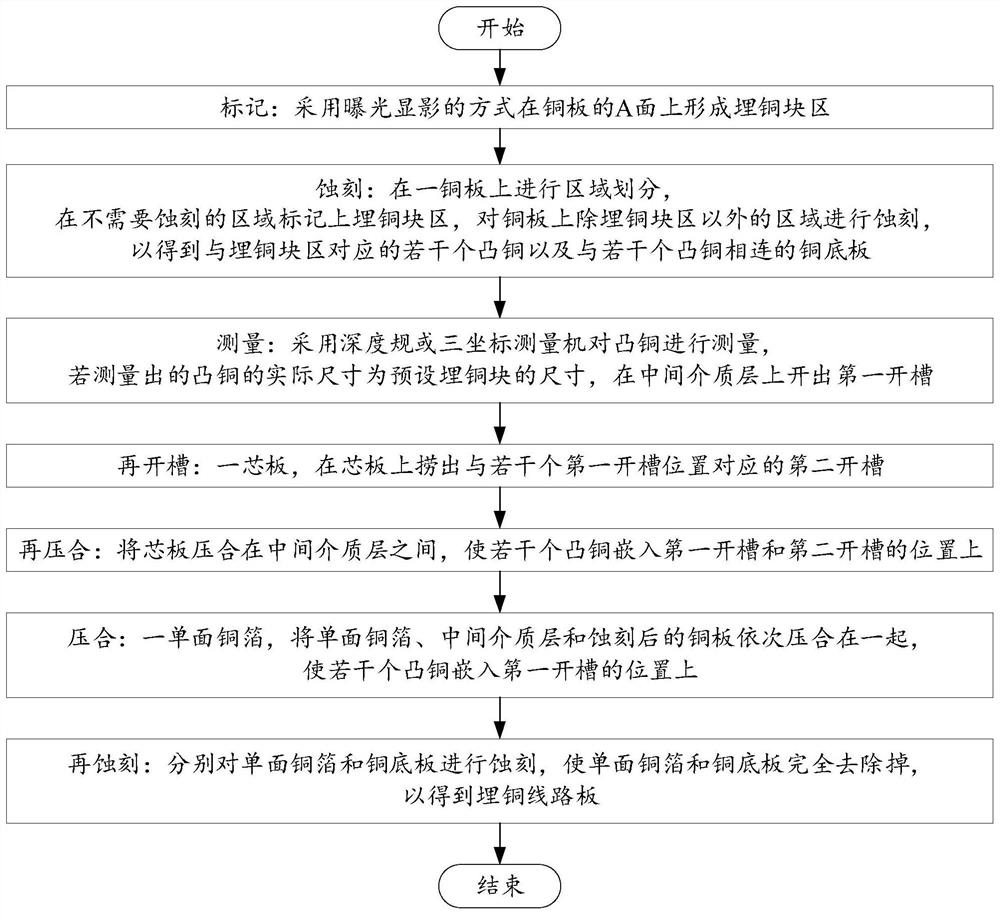

[0038] see Figure 1 to Figure 10 , the manufacturing method of the buried copper circuit board of this embodiment includes the following steps:

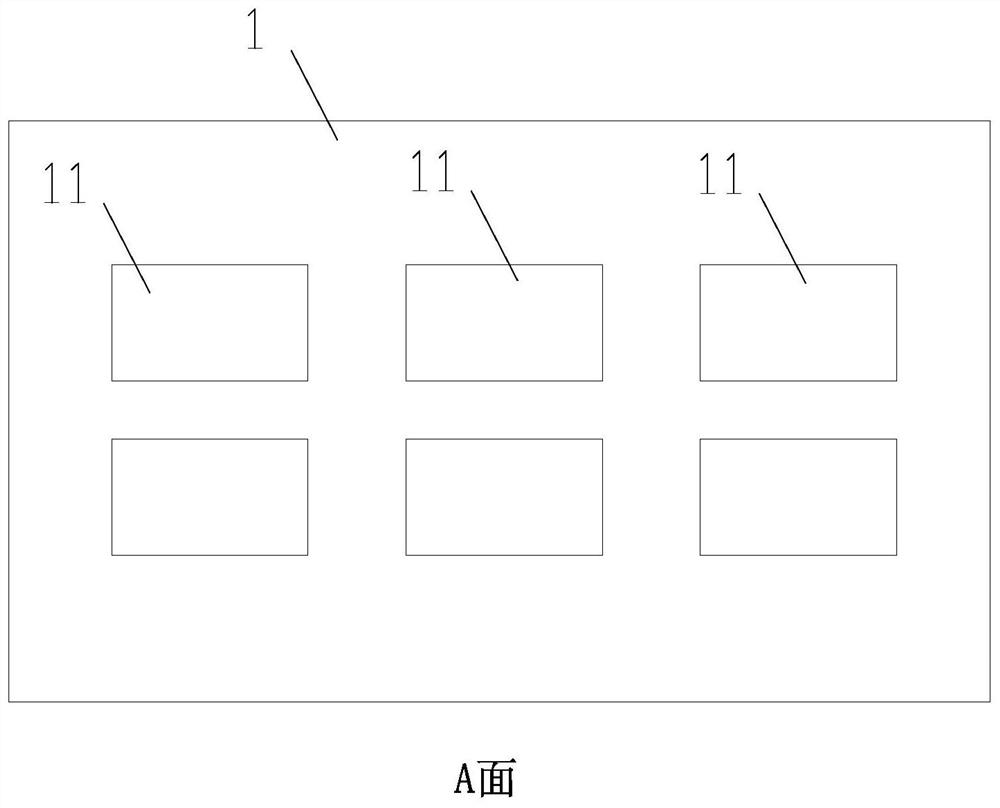

[0039] Etching: perform area division on a copper plate 1, mark the buried copper block area 11 on the area that does not need to be etched, and etch the area on the copper plate 1 except the buried copper block area 11 to obtain the buried copper block area 11. A number of bump copper 12 and a copper base plate 13 connected to a number of bump copper 12;

[0040] Slotting: an intermediate dielectric layer 2, on which a first slot 21 corresponding to the positions of several protruding coppers 12 is opened;

[0041] Pressing: a single-sided copper foil 3, the single-sided copper foil 3, the intermediate dielectric layer 2 and the etched copper plate 1 are pressed together in turn, so that several convex coppe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com