Array substrate, manufacturing method thereof and display panel

A technology of array substrates and substrate substrates, which is applied in semiconductor/solid-state device manufacturing, instruments, semiconductor devices, etc., can solve problems such as signal attenuation of metal signal lines, abnormal screen display, etc., and achieve the effect of solving display abnormalities and improving display quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

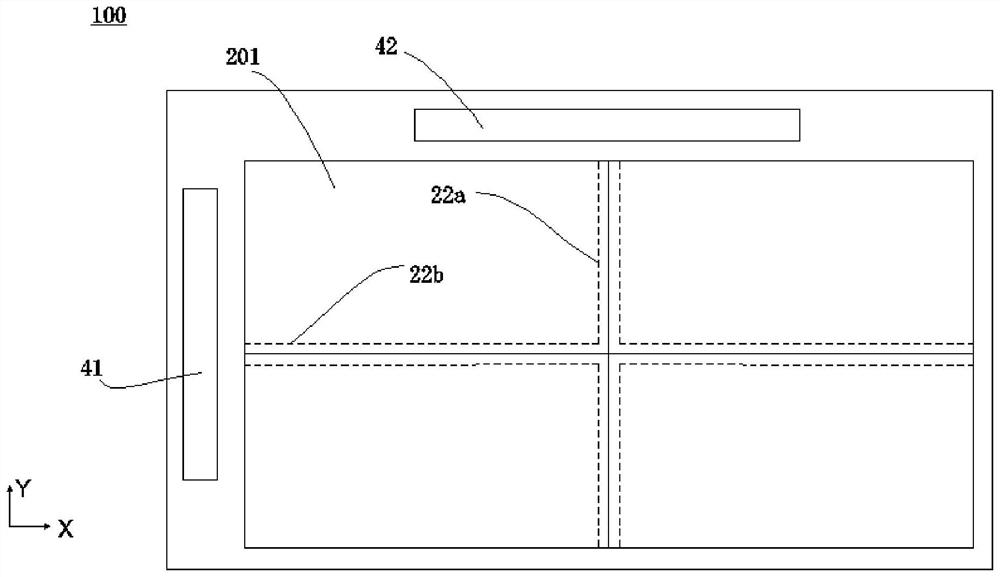

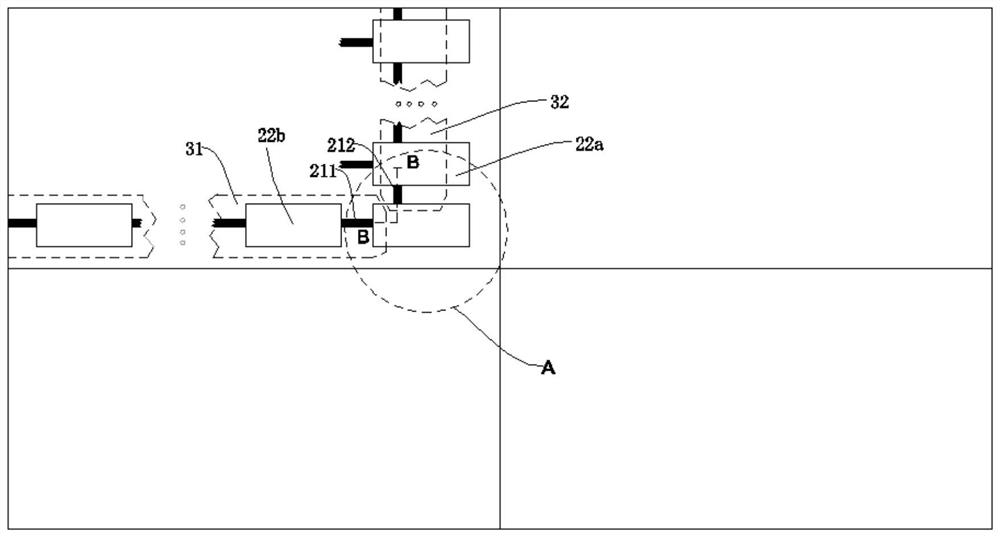

[0054] A first embodiment of the first aspect of the present application provides an array substrate. Please refer to Figure 1 to Figure 5 , the array substrate 100 includes a base substrate 10 , a display circuit 20 and an auxiliary circuit 30 disposed on the base substrate 10 .

[0055] The base substrate 10 includes a first surface 11 and a second surface 12 disposed opposite to each other, and a plurality of through holes 13 penetrating the first surface 11 and the second surface 12 are provided on the base substrate 10 .

[0056] The display line 20 is disposed on the first surface 11 , and the display line 20 includes a signal line 21 connected with the driving circuit and a thin film transistor (TFT) 22 connected with the signal line 21 . The display circuit 20 is used for transmitting the driving signal provided by the driving circuit to the thin film transistor 22 , so as to control the on-off of the thin film transistor 22 and provide a preset voltage to the thin f...

no. 2 example

[0085] A second embodiment of the second aspect of the present application provides a method for manufacturing an array substrate. Please refer to Figure 1 to Figure 6 , the manufacturing method of the array substrate includes the following steps.

[0086] Step S110 : providing a base substrate 10 , the base substrate 10 includes a first surface 11 and a second surface 12 disposed opposite to each other.

[0087] The base substrate 10 may be a transparent glass substrate, but is not limited thereto.

[0088] Step S120 : forming the display circuit 20 on the first surface 11 .

[0089] The display line 20 includes a signal line 21 and a thin film transistor 22 connected to the signal line 21; the signal line 21 has a proximal end close to the driving circuit and a distal end far away from the driving circuit.

[0090] Specifically, the signal line 21 includes a scan line 211 for connecting the gate driving unit 41 and a data line 212 for connecting the data driving unit 42;...

no. 3 example

[0121] A third embodiment of the third aspect of the present application provides a display panel. Please refer to Figure 12 The display panel 1 includes the array substrate 100 according to the first aspect, the opposite substrate 200 disposed opposite to the array substrate 100, and the liquid crystal layer 300 disposed between the array substrate 100 and the opposite substrate 200, wherein the opposite substrate 200 can be It is a color filter substrate provided with a color filter film, but is not limited thereto. For example, a color filter film can also be provided on the array substrate 100 .

[0122] The above-mentioned display panel 1 solves the problems of abnormal picture display and splicing slits caused by signal attenuation of metal signal lines.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com