Ship warehouse management method, device and equipment and storage medium

A storage management and ship technology, applied in the field of storage management, can solve the problems of ship parts waste, large labor output, low access efficiency, etc., and achieve the effect of ensuring rationalization, improving efficiency and avoiding waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

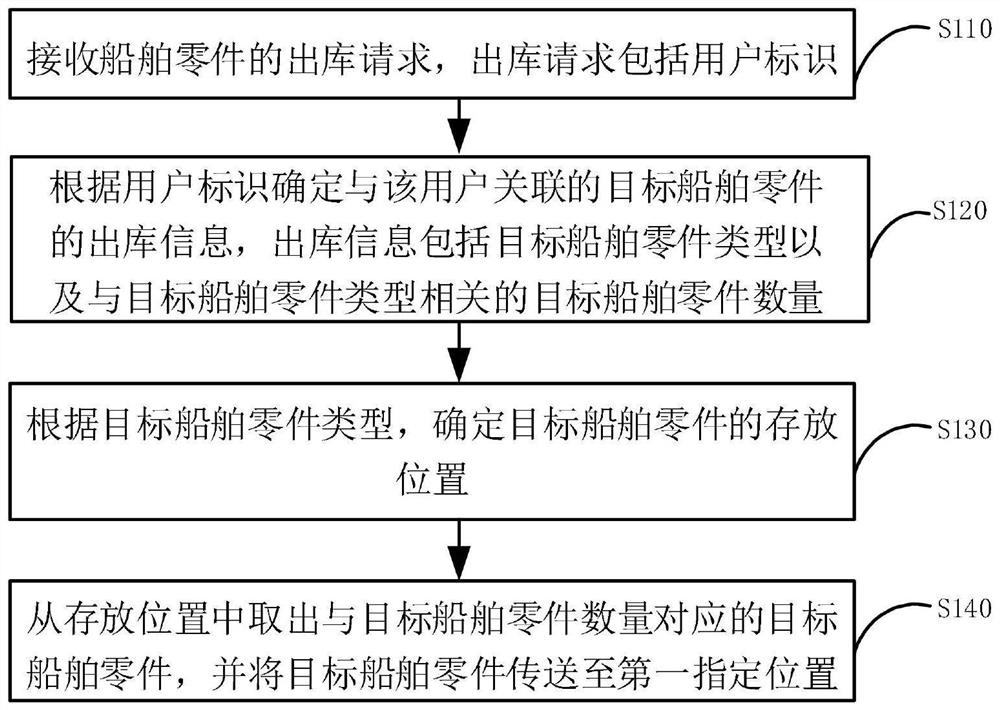

[0043] figure 1 Embodiment 1 of the present invention provides a method for ship storage management, which is applied to a ship storage system.

[0044] The intelligent and automated management method for ship warehousing disclosed in this embodiment is also applicable to industries similar to the shipbuilding industry that require large quantities of small parts, and can improve the efficiency of warehousing and distribution of small parts, thereby improving the efficiency of small parts warehousing and distribution. Shorten production cycle and improve production efficiency.

[0045] This embodiment is directed to the management operations performed on ship storage when ship parts are shipped out.

[0046] The method may be performed by a ship storage management device, and the pair of ship storage management devices may be implemented in the form of hardware and / or software.

[0047] like figure 1 As shown, the method includes the following steps:

[0048] S110: Receive...

Embodiment 2

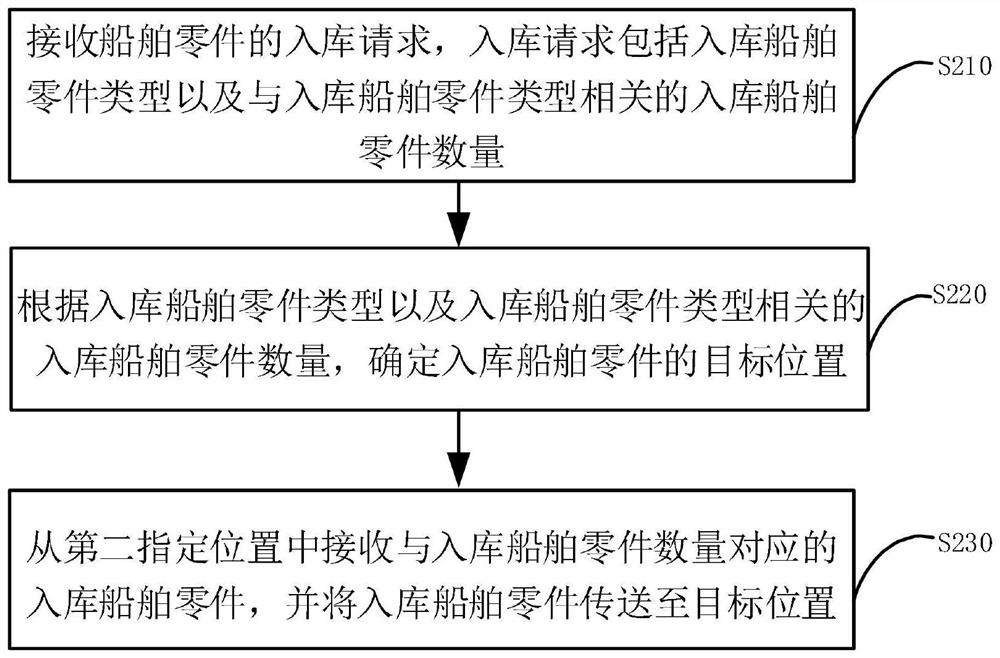

[0098] figure 2 A method for ship storage management is provided for the second embodiment of the present invention, and the method is applied to a ship storage system.

[0099] This embodiment is directed to the management operations performed on the ship storage when ship parts are put into storage.

[0100] like figure 2 As shown, the method includes the following steps:

[0101] S210: Receive a warehousing request for ship parts, where the warehousing request includes the type of the warehousing ship part and the quantity of the warehousing ship part related to the type of the warehousing ship part.

[0102] A warehousing request can be initiated by a warehouse manager with warehousing authority. In order to better track the processing of ship parts, information can be collected from the user who initiated the warehousing request to confirm that they have warehousing authority. After confirming that the user has the warehousing authority, the warehousing user can inpu...

Embodiment 3

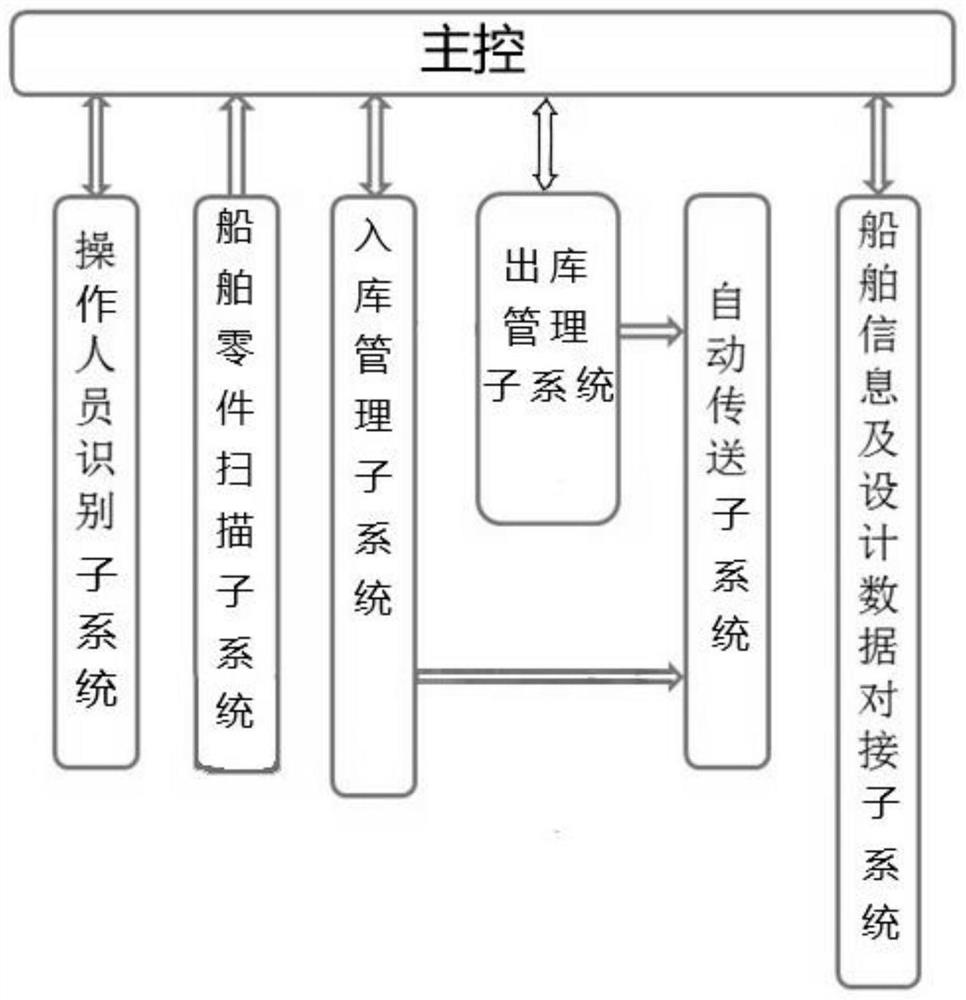

[0141] Figure 4 A schematic structural diagram of a device for ship storage management provided in Embodiment 3 of the present invention, the device is applied in a ship storage system, such as Figure 4 As shown, the device includes the following modules:

[0142] an out-of-warehouse request receiving module 410, configured to receive an out-of-warehouse request for ship parts, where the out-of-warehouse request includes a user ID;

[0143] An out-of-warehouse information determination module 420, configured to determine out-of-warehousing information of a target ship part associated with the user according to the user identification, where the out-of-warehouse information includes a target ship part type and a target ship related to the target ship part type number of parts;

[0144] The storage location determination module 430 determines the storage location of the target ship part according to the type of the target ship part;

[0145] A take-out module 440, configure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com