Intelligent warehousing system

A warehousing system and smart technology, applied in the direction of conveyor objects, transportation and packaging, storage devices, etc., can solve the problems of low utilization rate of storage space, low level of automation, and the space above the warehouse cannot be effectively used, so as to avoid out Warehouse errors and the effect of improving delivery efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be described in detail below in conjunction with the accompanying drawings, so that those of ordinary skill in the art can implement it after referring to this specification.

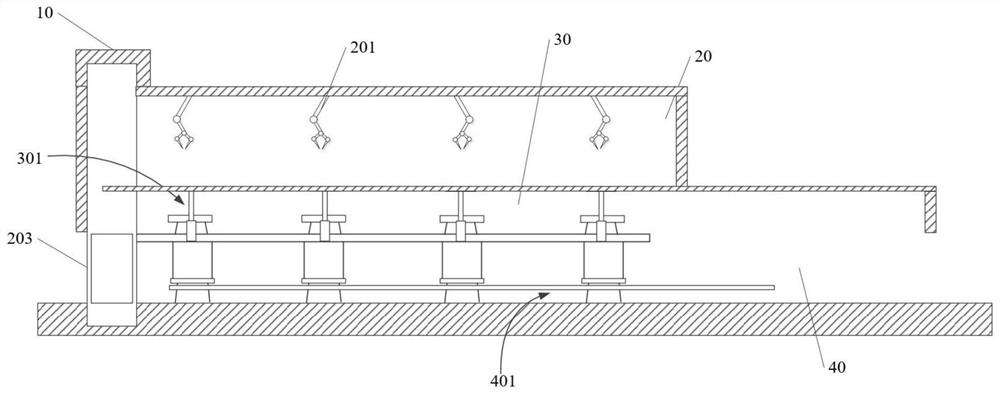

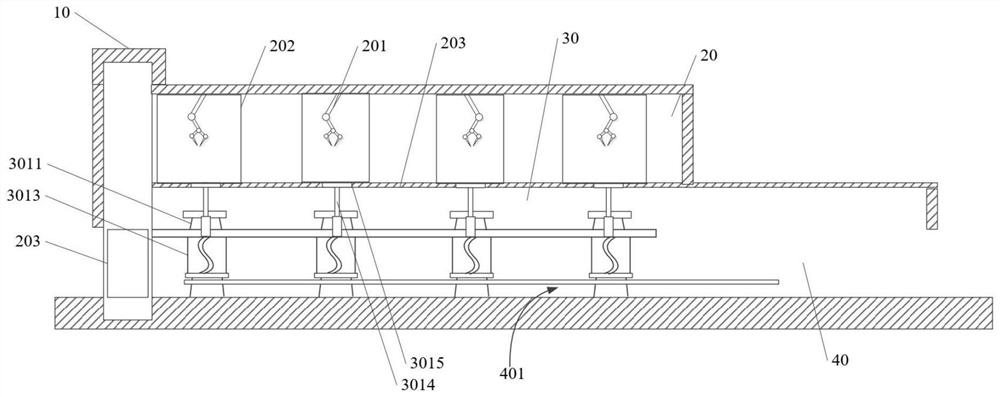

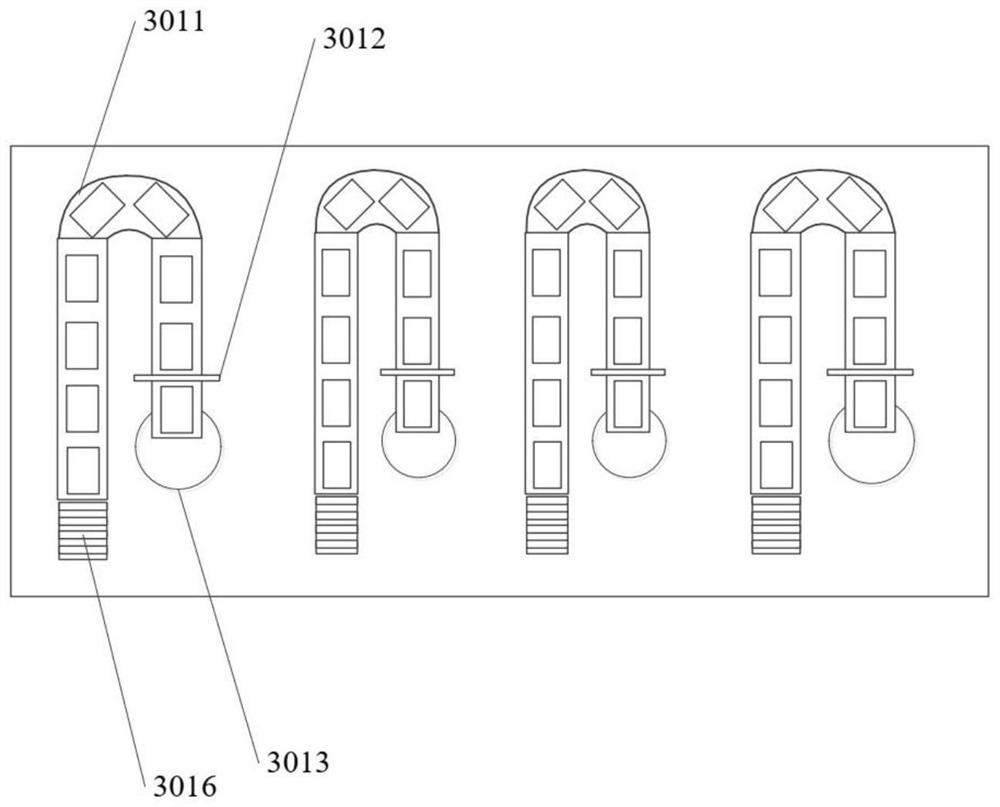

[0043] Such as figure 1As shown, a smart storage system includes: a high-rise warehouse 10, which includes a cargo storage area 20 and a cargo delivery piece counting area 30 connected from top to bottom; side, and the summary inspection area is set close to the warehouse exit; multiple mechanical arms 201 are slidingly set on the ceiling of the cargo storage area; the upper ends of multiple mechanical arms are realized in the designated area through the structure of sliding rails and sliders Sliding picking; piece counting transmission component 301, which is arranged in the cargo conveying piece counting area; summary transmission component 401, which is set in the summary verification area; and control center, which includes: outbound order analysis module, outbound ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com