Nondestructive online monitoring method and device based on spectrum method

A monitoring device and a spectroscopic technique, applied in the field of high-voltage electrical equipment, can solve the problems of mixing impurity pump as a power unit return gas, easy mixing of oil and gas, etc., to achieve the effects of high sensitivity and simple device structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

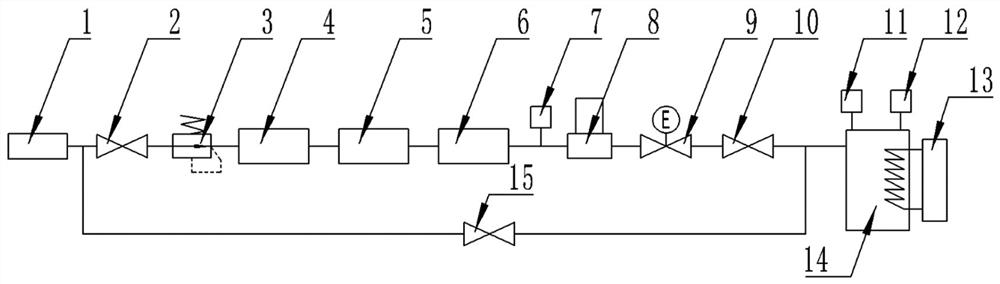

[0039] The present invention provides an embodiment, which is a nondestructive online monitoring method and device based on spectroscopy. like figure 1 shown, figure 1 It is a schematic diagram of the structure of the present invention.

[0040] exist figure 1 , the intake port 1, the first solenoid valve 2, the pressure reducing valve 3, SO 2 Fluorescence detection unit 4, CO infrared absorption detection unit 5, CF 4 The infrared absorption detection unit 6, the first pressure sensor 7, the flow meter 8, the regulating valve 9, the second solenoid valve 10, and the collection tank 14 are connected in series through the pipeline in turn; one end of the third solenoid valve 15 is connected to the first electromagnetic valve through the pipeline. The valve 2 is connected, and the other end of the third solenoid valve 15 is communicated with the rear end of the second solenoid valve 10 through the pipeline; the first pressure sensor 11 and the temperature sensor 12 are insta...

Embodiment 2

[0046] The present invention provides another embodiment, which is a nondestructive online monitoring method based on spectroscopy, which utilizes the nondestructive online monitoring device based on spectroscopy described in Embodiment 1 to perform online monitoring, which specifically includes the following steps:

[0047] Step 1. Preparation phase.

[0048] Including: (1) Vacuuming: vacuuming the online monitoring device;

[0049] Connect the air inlet 1 of the online monitoring device to the vacuuming device with high pressure gas above 0.2MPa (abs), and open all solenoid valves, including: the first solenoid valve 2, the second solenoid valve 10 and the third solenoid valve 15; Start the vacuuming device to vacuumize the online monitoring device of the present invention until the pressure detected by the first pressure sensor 7 and the second pressure sensor 11 is lower than 133Pa, close all solenoid valves, and stop vacuuming.

[0050] (2) Refrigeration: the temperature...

Embodiment 3

[0064] The present invention provides another embodiment, which is a nondestructive online monitoring method based on spectroscopy, using the nondestructive online monitoring device based on spectroscopy described in Embodiment 1 for online monitoring, wherein: if the detection process needs to be SF 6 All the gas released from the insulating gas chamber is recharged, and the on-site non-destructive online monitoring of the gas chamber can be fully realized. The following operations can be performed:

[0065] Before using the device of the present invention to monitor the gas chamber online, open the third solenoid valve 15, and at normal temperature, pass pure SF into the collection tank 14 from the air inlet 1 6 gas until the second pressure sensor 11 detects that the pressure value is 0.4655MPa. According to formula (3), the SF in the collection tank 14 is calculated at this time. 6 The density is 29.53kg / m 3. Through the above method, the gas density in the collection t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com