Automatic butt joint mechanism and butt joint method for gas water heating device detection equipment

A detection equipment, gas hot water technology, applied in the direction of lighting and heating equipment, fluid heater, fluid heater control, etc., can solve the problems of difficult use and control, prone to failure, high coordination accuracy, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

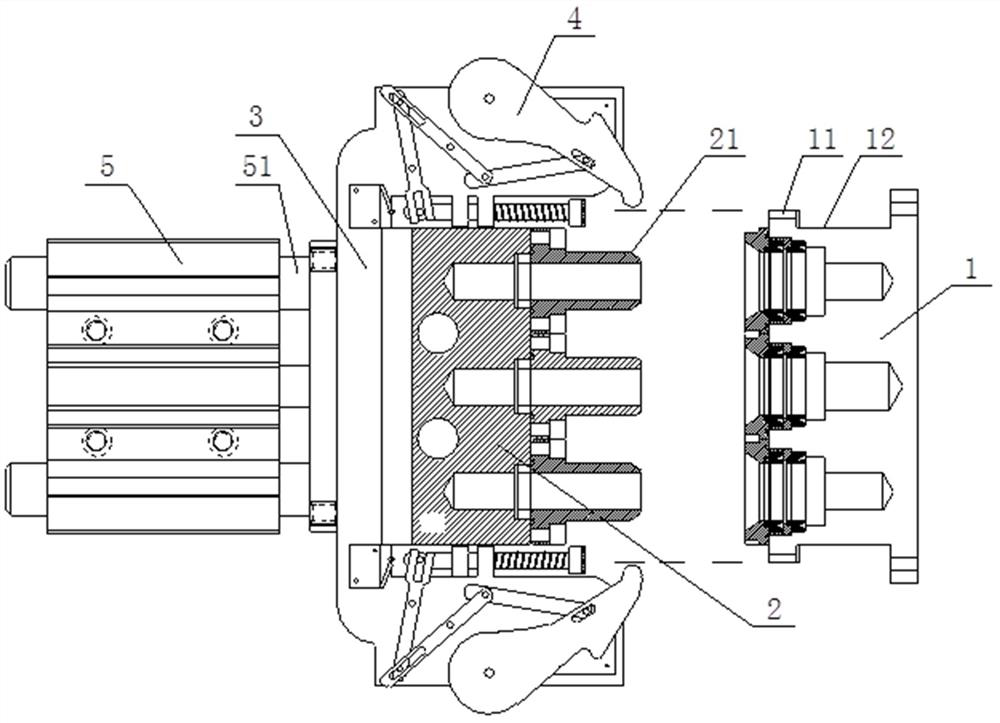

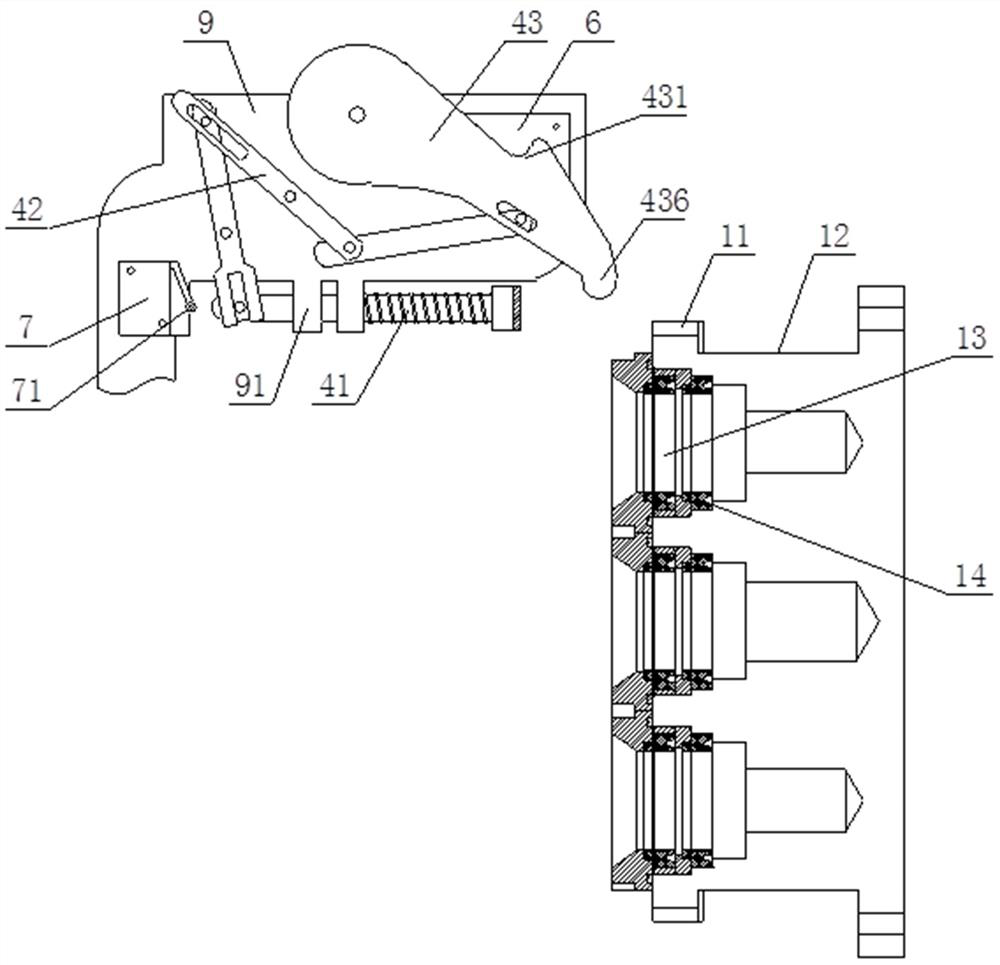

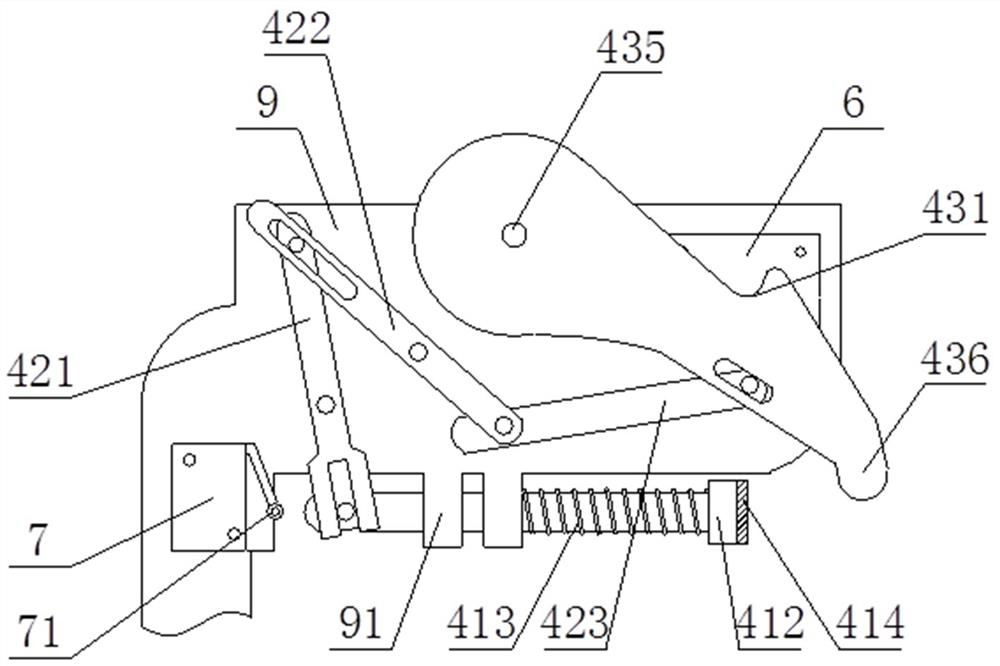

[0036] like Figures 1 to 8 As shown in the figure, the automatic docking mechanism for the detection equipment of the gas-fired hot water device provided in this embodiment includes a docking male seat 2 and a base 3 that are adapted to the docking female seat 1, and are fixed on the base 3 and located in the docking male seat 2. More than two automatic locking mechanisms 4 and male seat driving cylinders 5 on the side, wherein at least one insertion hole 13 is provided on the docking female seat 1, and at least two V-shaped sealing rings 14 are arranged in the insertion hole 13, The provision of a plurality of V-shaped sealing rings 14 is beneficial to prevent the leakage of gas. At least one plug post 21 is provided on the docking male seat 2 which is adapted to the plug hole 13, and the docking male seat 2 is fixed on the base 3. The automatic locking mechanism 4 includes a resettable horizontal striker 41, a power transmission mechanism 42 and a rotating lock tongue 43. T...

Embodiment 2

[0043] like Figure 8 As shown, a docking method provided in this embodiment is used for the automatic docking mechanism used in the above-mentioned gas-fired hot water device detection equipment, and the docking method includes a locking operation and an unlocking operation of automatically locking the docking mechanism. The locking operation of the automatic locking docking mechanism is carried out as follows:

[0044]S10: The controller 8 sends the first cylinder driving command to the male seat driving cylinder 5, and the male seat driving cylinder 5 drives the docking male seat 2 to move to the locking target position after receiving the first cylinder driving command, and makes the docking female seat 1 inserted In the docking male seat 2, the target locking position usually refers to the position where one end of the resettable horizontal striker 41 touches the travel switch 7, so that the controller 8 generates the locking control in the lock control signal according t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com