Ventilation shaft assembly type steel structure anti-collapse shed frame in civil air defense construction

A technology for ventilation shafts and civil air defense projects, which is applied to building components, vertical pipes, building structures, etc. It can solve the problems of affecting city appearance and high height of anti-collapse scaffolding, so as to save time, reduce the pressure of dredging and maintenance, and improve the flexibility of use sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

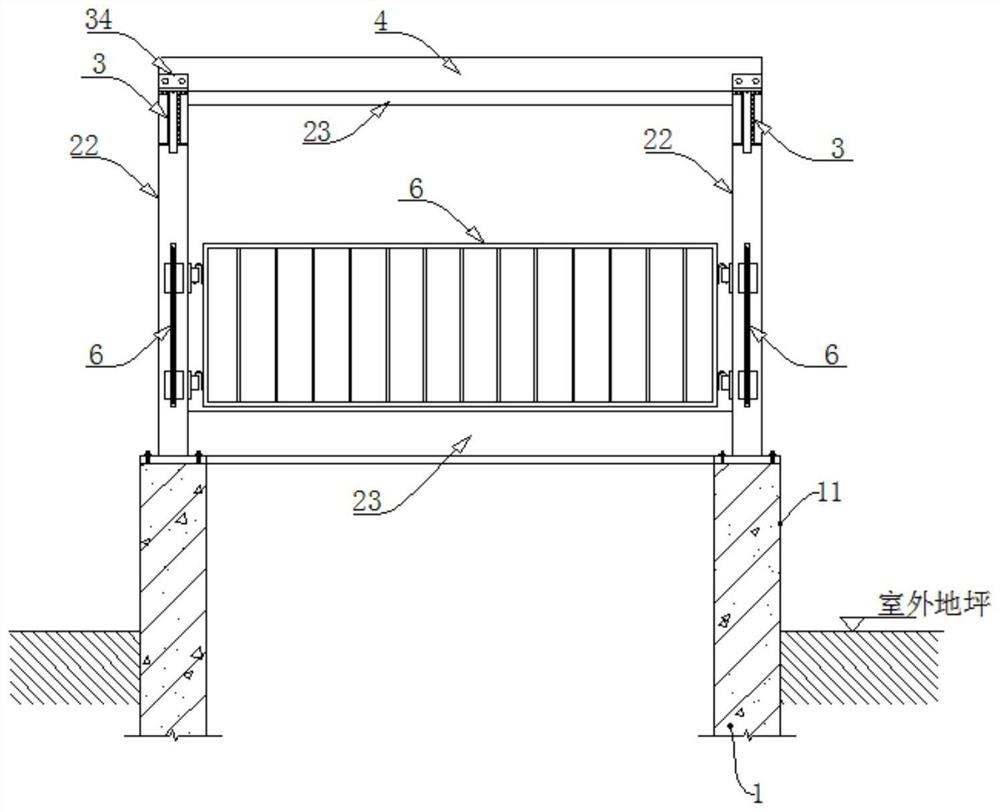

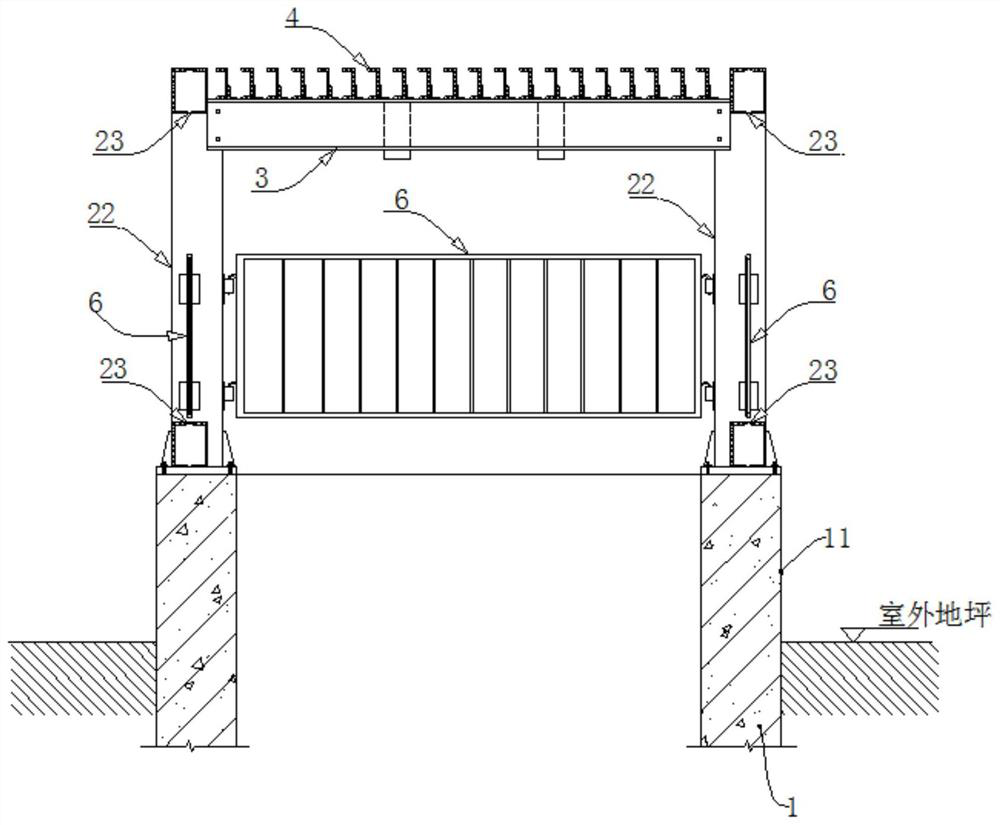

[0082] like Figure 1-3 As shown, a steel structure anti-collapse scaffolding for ventilation shafts in a civil air defense project includes a steel structure scaffolding and a cover plate structure.

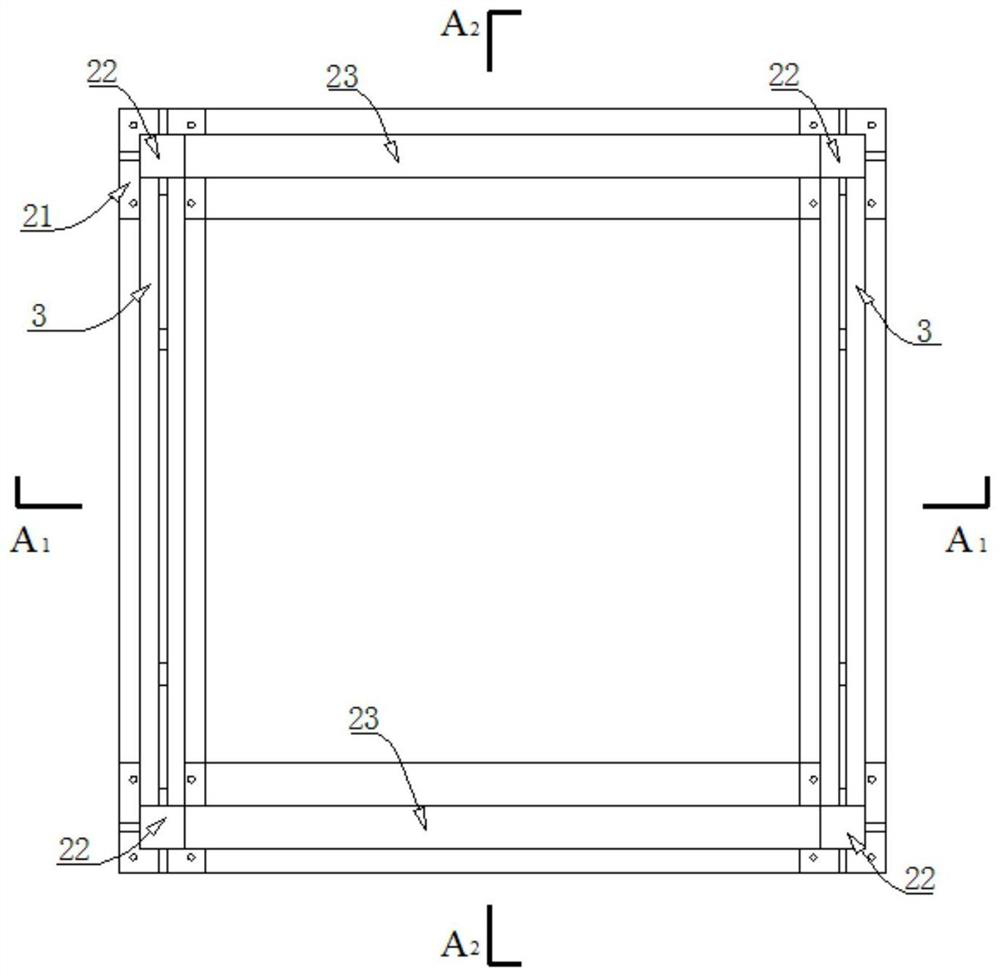

[0083] The steel structure scaffolding includes a support frame 2 , a main support rod 3 , a secondary support rod 4 , a rain tile 5 , and a protective railing 6 . figure 1 In the top view of the steel structure scaffold of this embodiment, in order to clearly show the positional relationship between the support frame 2 and the main support rod 3, the auxiliary support rod 4 and the rain-proof tile 5 are not shown.

[0084] like figure 1 As shown, at least two supporting frames 2 are arranged side by side. For the case where the lateral span is less than or equal to 2100mm, two supporting frames 2 can be arranged side by side; for the case where the lateral span is greater than 2100mm, multiple supporting frames need to be arranged side by side. The long sides of the support...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com