Soil sampling device for testing compactness of roadbed for engineering supervision

A technology of earth-taking device and compaction degree, which is applied in the field of soil-taking device for engineering supervision to test the degree of subgrade compaction, and can solve the problems of time-consuming and labor-intensive

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

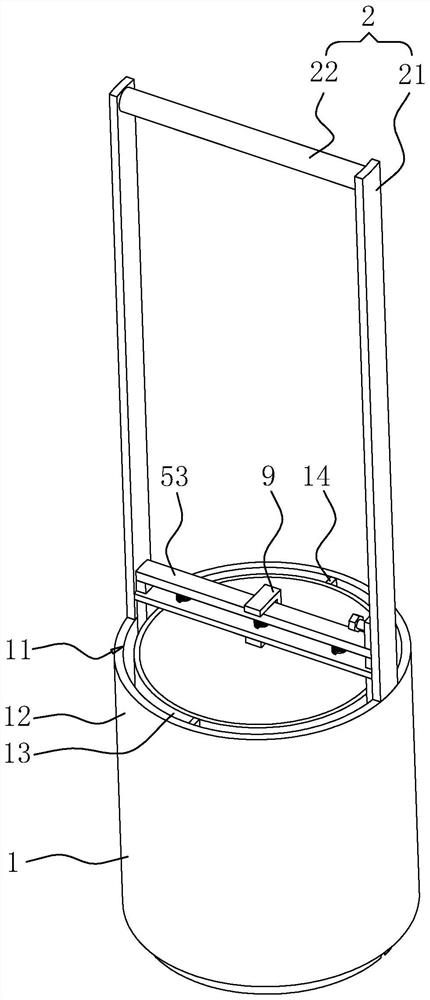

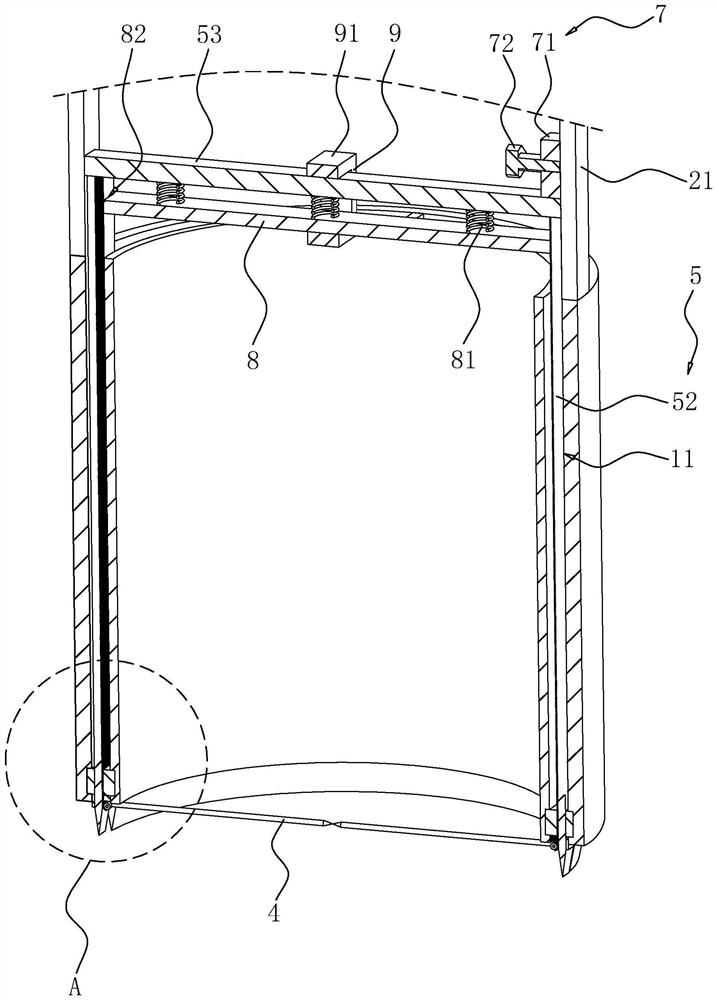

[0032] Attached to the following Figure 1-4 This application will be described in further detail.

[0033] The embodiment of the present application discloses a soil borrowing device for a roadbed compaction degree test for engineering supervision. refer to figure 1 , the soil extraction device includes an annular knife 1, the upper surface of the annular knife 1 is fixedly connected with a fixing frame 2, and the fixing frame 2 includes two fixed rods 21 and a connecting rod 22 fixed between the two fixed rods 21. Each fixed rod 21 are all arranged parallel to the axis of the annular knife 1 .

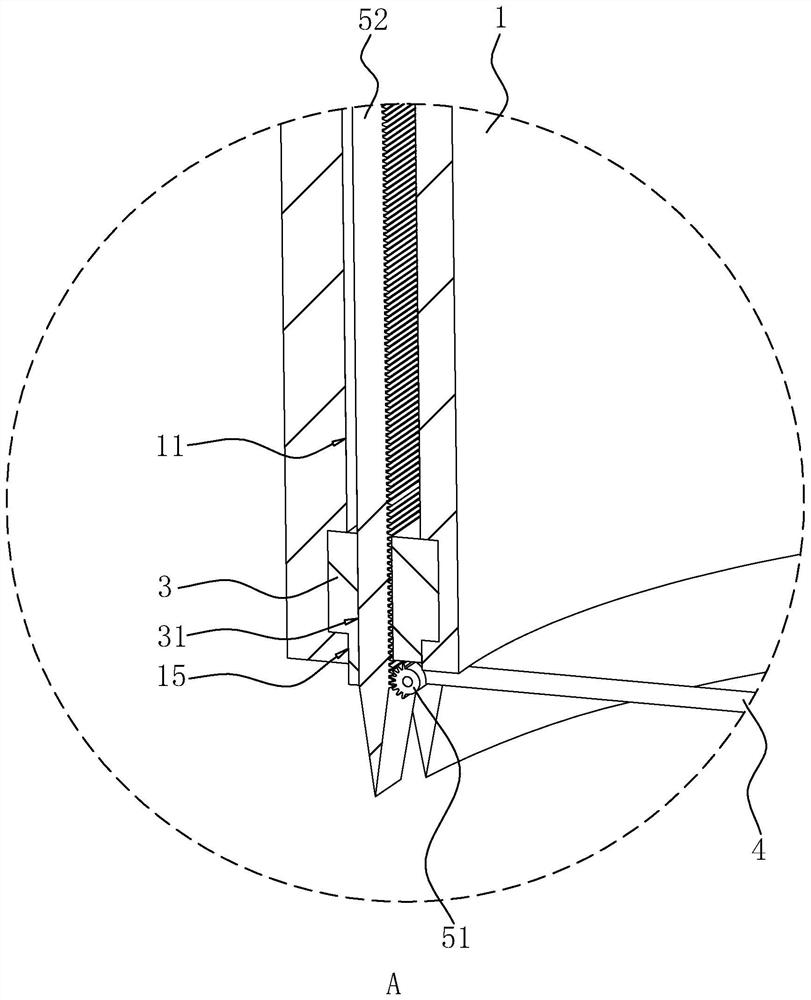

[0034] refer to figure 2 and image 3 , the bottom end of the annular knife 1 is slidably connected with two sliding blocks 3 , and the two sliding blocks 3 rotate around the axis of the annular knife 1 . The bottom end of each sliding block 3 is rotatably connected with a dividing needle 4 arranged vertically downward, and a driving assembly 5 is commonly connected to the two ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com