Full-automatic product printing and dyeing production line and production process thereof

A production process and fully automatic technology, applied in the field of printing and dyeing, can solve problems such as time-consuming, insufficient dyeing uniformity, poor curing effect, etc., to achieve the effect of improving curing effect and reducing printing and dyeing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

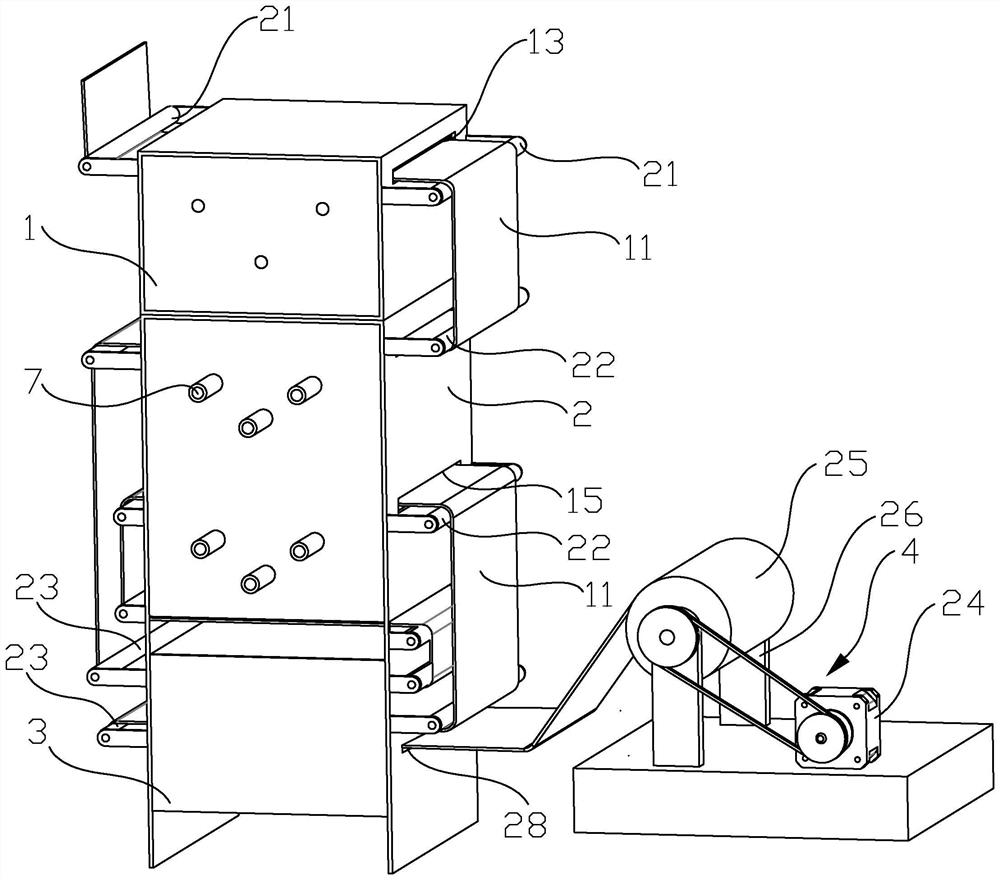

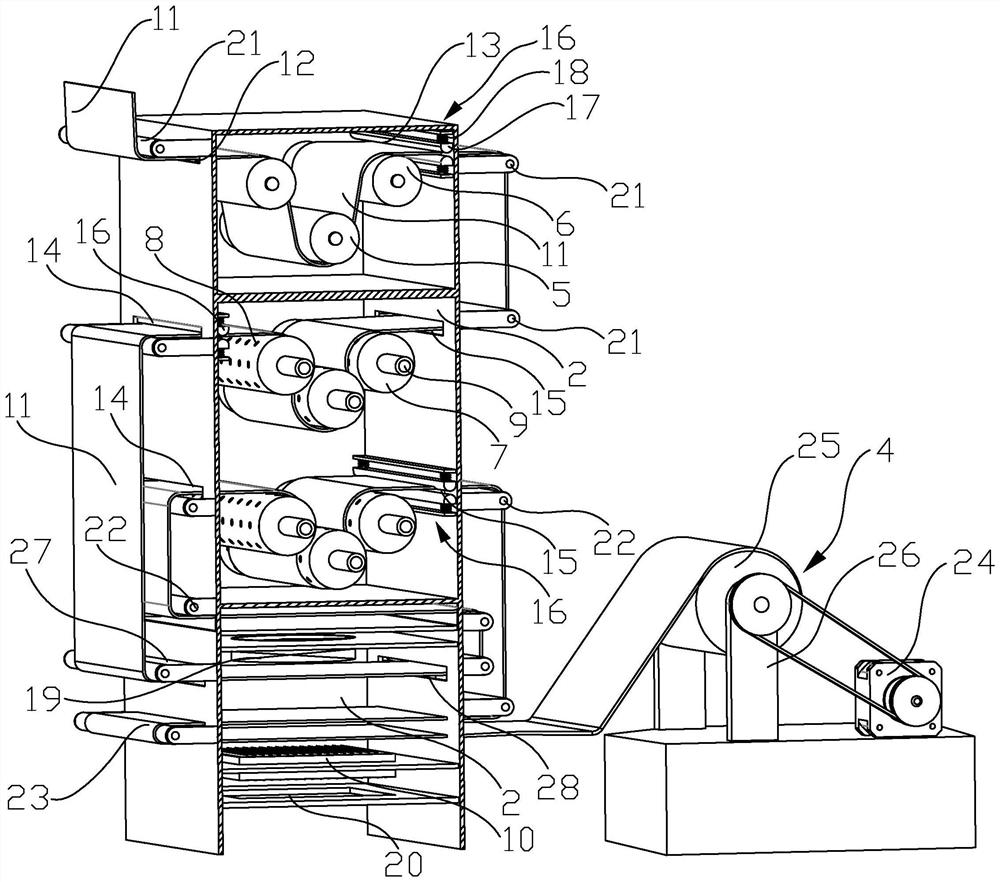

[0031] This embodiment discloses a fully automatic product printing and dyeing production line, see figure 1 and figure 2 , The automatic product printing and dyeing production line includes a water immersion box 1, a printing and dyeing box 2, a drying box 3 and a winding mechanism 4. The water immersion box 1, the printing and dyeing box 2 and the drying box 3 are arranged in order in the vertical direction, and the printing and dyeing box 2 rotates horizontally. A plurality of staggered and offset dyeing rolls 7 are installed. The dyeing roll 7 is a hollow structure, and the roll surface of the dyeing roll 7 is distributed with a plurality of injection holes 8 that communicate with its inner cavity 9. The inner cavity 9 of the dyeing roll 7 passes through the slurry. The pipe is communicated with the outlet of the grouting pump, and there is a feeding pipe between the bottom of the printing and dyeing box 2 and the inlet of the grouting pump; an electric heating element 10...

Embodiment 2

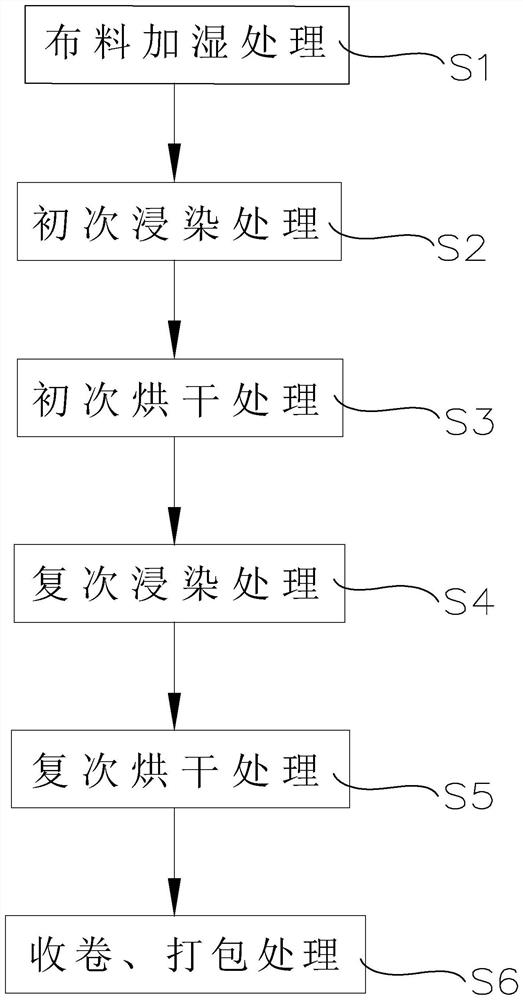

[0039] This embodiment discloses a fully automatic product printing and dyeing production process, see figure 2 and image 3 , the fully automatic product printing and dyeing production line used to implement the production process, the specific process steps are as follows:

[0040] S1, the cloth 11 is humidified, the cloth 11 to be dyed is immersed in clean water through the soaking roller 5, the water pressing roller 6 squeezes the water on the surface of the cloth 11 to be dyed to the inside, and then squeezes the cloth to be dyed through the extrusion mechanism 16. Excessive moisture adhered to 11;

[0041] S2, the initial dispersing treatment, the material injection hole 8 on the surface of the dispersing roller 7 sprays the dye liquor on the surface of the cloth 11 to be dyed, and the dye liquor is rolled to the inside of the cloth 11 through the dispersing rollers 7 of the upper layer dispersing roller 7 group, and then Extrude the excess dye liquor adhering to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com