Saline-alkali soil conditioner as well as preparation method and application thereof

A soil conditioner and a technology for saline-alkali land, applied in the agricultural field, can solve problems such as unsatisfactory improvement effect and inability to comprehensively improve soil structure, and achieve the effects of increasing content, increasing crop yield, and reducing soil compaction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The present invention also provides the preparation method of the described saline-alkali soil conditioner, comprising the following steps:

[0036] (1) mixing animal manure, crop straw, rice husk and EM bacterial inoculum to obtain fermentation material, and stacking and fermenting the fermentation material for 20-30 d to obtain decomposed clinker;

[0037] (2) mixing the decomposed clinker with biochar, fly ash, humic acid, polypeptide amino acid, and ferrous sulfate, and granulating to obtain a saline-alkali soil conditioner.

[0038] In the present invention, the water content of the fermentation material during the stacking fermentation is 61-65%, preferably 63%; the central temperature of the fermentation stack during the stacking fermentation is 30-60°C, preferably 40-50°C, and further Preferably, the temperature is 45°C; the stacking fermentation time is preferably 25d; when the central temperature of the fermentation stack is >60°C, the stack is turned over imm...

Embodiment 1

[0048] Take 25kg of chicken manure, 25kg of duck manure, 40kg of soybean straw, 25kg of rice husk and 0.02kg of EM bacterial agent, and then pile and ferment for 25d under the condition of water content of 62% to obtain decomposed clinker. During the stacking fermentation, the core temperature of the fermentation pile should not exceed 60°C. Once it exceeds 60°C (including 60°C), the pile should be turned over immediately. The obtained decomposed clinker was mixed with 18kg of biochar, 10kg of fly ash, 10kg of humic acid, 2kg of polypeptide amino acid, and 3kg of ferrous sulfate in a granulator to obtain a soil conditioner for saline-alkali soil.

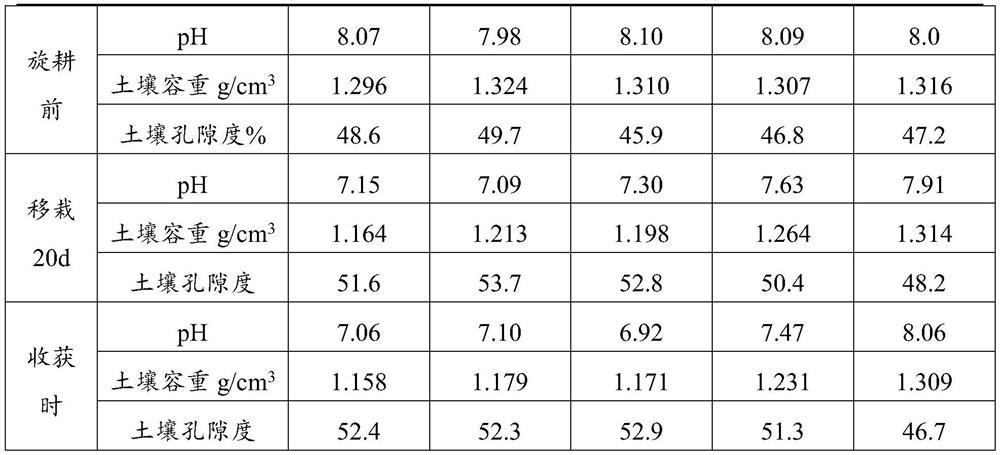

[0049] During the rotary tillage on April 18, 2020, the saline-alkali soil conditioner was applied in the amount of 1kg / mu, and the rice seedlings were transplanted on May 7 according to the plant-row spacing of 4cm. After transplanting, manage according to conventional methods. The pH, soil bulk density, and soil porosity of the s...

Embodiment 2

[0052] Take 60kg of chicken manure, 10kg of corn stalk, 20kg of peanut straw, 28kg of rice husk and 0.01kg of EM bacterial agent, and then pile and ferment for 20 days under the condition of water content of 65% to obtain decomposed clinker. During the stacking fermentation, the core temperature of the fermentation pile should not exceed 60°C. Once it exceeds 60°C (including 60°C), the pile should be turned over immediately. The obtained decomposed clinker was mixed with 15kg of biochar, 8kg of fly ash, 8kg of humic acid, 4kg of polypeptide amino acid, and 2kg of ferrous sulfate in a granulator to obtain a soil conditioner for saline-alkali soil.

[0053]During the rotary tillage on April 18, 2020, the saline-alkali soil conditioner was applied in the amount of 2 kg / mu, and the rice seedlings were transplanted on May 7 according to the plant-row spacing of 4 cm. After transplanting, manage according to conventional methods. The pH, soil bulk density, and soil porosity of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com