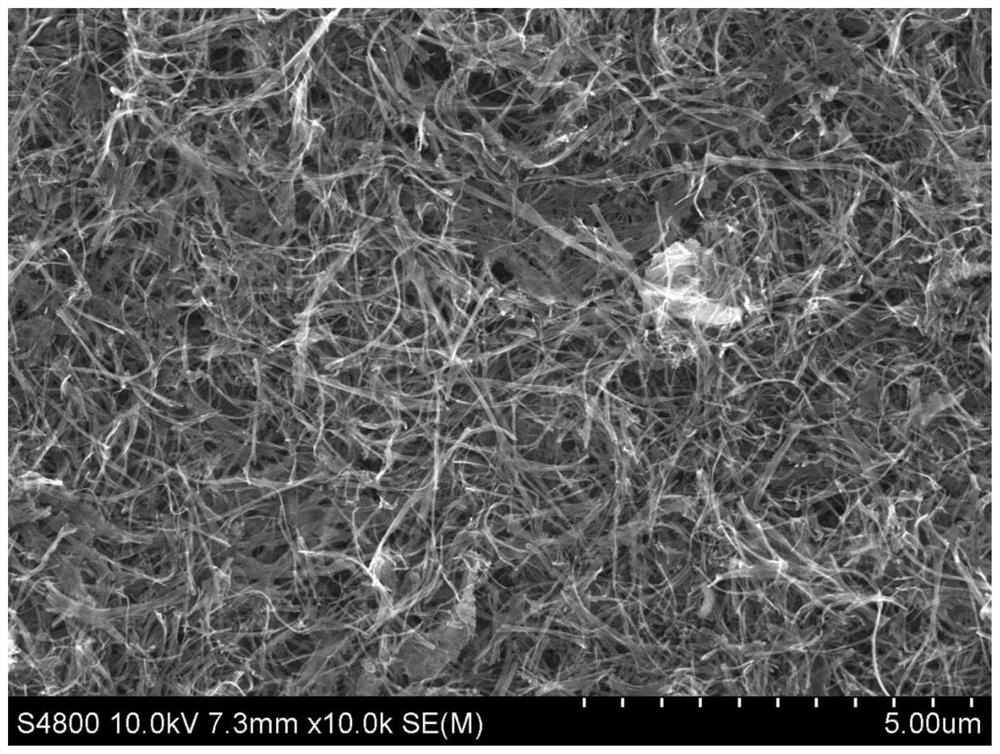

Carbon fiber aerogel protected bismuth nanocluster and preparation method thereof

A carbon fiber aerogel, bismuth nanotechnology, applied in separation methods, chemical instruments and methods, dispersed particle separation, etc., can solve the problems of limited CDI system application, inapplicability of wet chemical methods, lack of research, etc., and achieve excellent cycle stability. The effect of stability and stability of ultrafast desalination cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A preparation method of carbon fiber aerogel-protected bismuth nanoclusters, comprising the following steps:

[0032] 1) Take the BC hydrogel (4×4×1cm) and wash it with deionized water to pH 6.5;

[0033] 2) The washed BC hydrogel was placed in 200 mL of Bi(NO) with a concentration of 20 wt%. 3 ) 3 Soak in aqueous solution for 48 hours to make bismuth ions (Bi 3+ ) was immersed in the BC skeleton, and the immersed BC hydrogel was frozen at minus 40 °C for 48 hours in an ultra-low temperature refrigerator, and then placed in a freeze dryer for 48 hours under the condition of pressure < 10Pa to obtain a composite aerogel. glue;

[0034] 3) Put the composite aerogel prepared in step 2) in a tube furnace at 10°C for min -1 The temperature was raised to 520 °C for high temperature carbonization for 1 hour, followed by 5 °C min -1 The heating rate was increased to 800 °C for 2 h under temperature-controlled gasification to obtain carbon fiber aerogel-protected bismuth na...

Embodiment 2

[0036] A preparation method of carbon fiber aerogel-protected bismuth nanoclusters, comprising the following steps:

[0037] 1) Take the BC hydrogel (4×4×1cm) and wash it with deionized water to pH 6.5;

[0038] 2) The washed BC hydrogel was placed in 200 mL of Bi(NO) with a concentration of 30 wt%. 3 ) 3 Soak in aqueous solution for 48 hours to make bismuth ions (Bi 3+ ) was immersed in the BC skeleton, and the immersed BC hydrogel was frozen at minus 40 °C for 48 hours in an ultra-low temperature refrigerator, and then placed in a freeze dryer for 48 hours under the condition of pressure < 10Pa to obtain a composite aerogel. glue;

[0039] 3) Put the composite aerogel prepared in step 2) in a tube furnace at 10°C for min -1 The temperature was raised to 520 °C for high temperature carbonization for 1 hour, followed by 5 °C min -1 The heating rate was increased to 800 °C for 2 h under temperature-controlled gasification to obtain carbon fiber aerogel-protected bismuth na...

Embodiment 3

[0041] A preparation method of carbon fiber aerogel-protected bismuth nanoclusters, comprising the following steps:

[0042] 1) Take the BC hydrogel (4×4×1cm) and wash it with deionized water to pH 6.5;

[0043] 2) The washed BC hydrogel was placed in 200 mL of Bi(NO) with a concentration of 40 wt%. 3 ) 3 Soak in aqueous solution for 72 hours to make bismuth ions (Bi 3+ ) was immersed in the BC skeleton, and the immersed BC hydrogel was frozen in an ultra-low temperature refrigerator below minus 40 °C for 48 hours, and then placed in a freeze dryer for 48 hours under the condition of a pressure <10Pa to obtain a composite gas. gel;

[0044] 3) Put the composite aerogel prepared in step 2) in a tube furnace at 10°C for min -1 The temperature was raised to 520 °C for high temperature carbonization for 1 hour, followed by 5 °C min -1 The heating rate was increased to 800 °C for 2 h under temperature-controlled gasification to obtain carbon fiber aerogel-protected bismuth nan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com