Multipurpose liquid cargo tank pipeline system and control method thereof

A pipeline system and cargo tank technology, applied in the field of clean fuel supply for ships, can solve the problems of not being able to make full use of different fuels from different gas sources, fixing the way of connecting pipelines, etc., so as to improve operation safety, flexible design and convenient operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

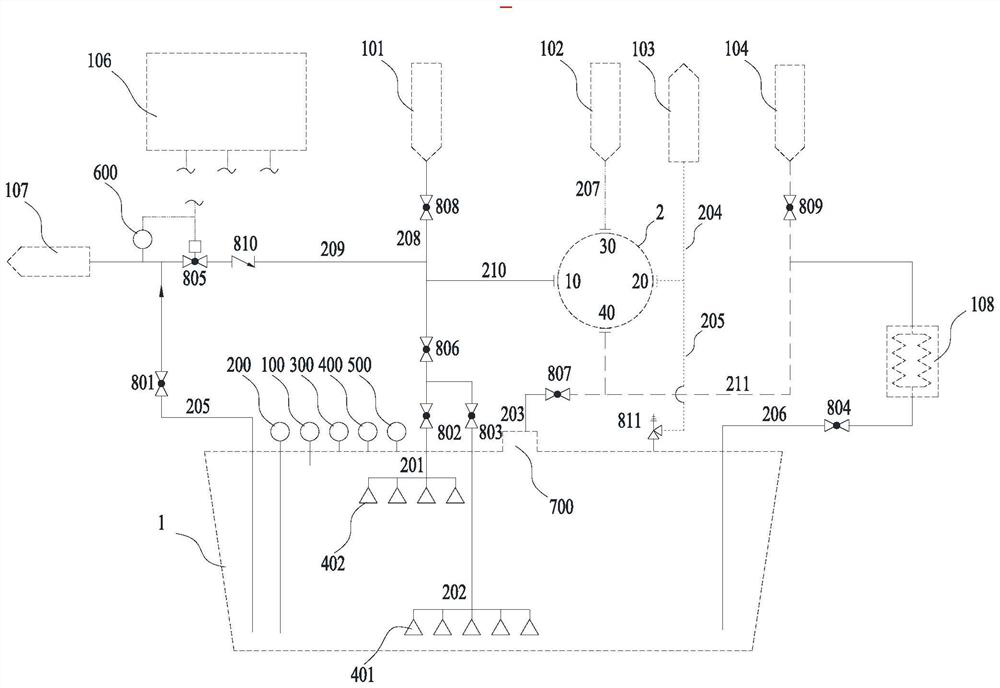

[0041] A multi-purpose cargo tank piping system for volume ≤ 1500m 3 and cargo tanks (1) with working pressure ≥ 4 barg, such as figure 1 As shown, it includes a cargo tank 1 at the lower end, a blow-off gas source 102 at the upper end, a vent mast 103, and an annular four-way connecting pipe 2; the multi-purpose cargo tank 1 pipeline system also includes connecting pipelines and equipment A valve on the connecting pipeline, and a bilge nozzle assembly 401 located at one end of the connecting pipeline and located at the bottom of the cargo tank 1, and a top nozzle assembly 402 located at the top of the cargo tank 1;

[0042] The molecular weight of the inert gas is smaller than the molecular weight of air, that is, when the inert gas is nitrogen, the inert gas starts from the purge gas source 102 and enters the cargo tank 1 from the top of the cargo tank 1; the air discharged from the bilge Starting from the nozzle assembly 401, it is discharged through the connecting pipelin...

Embodiment 2

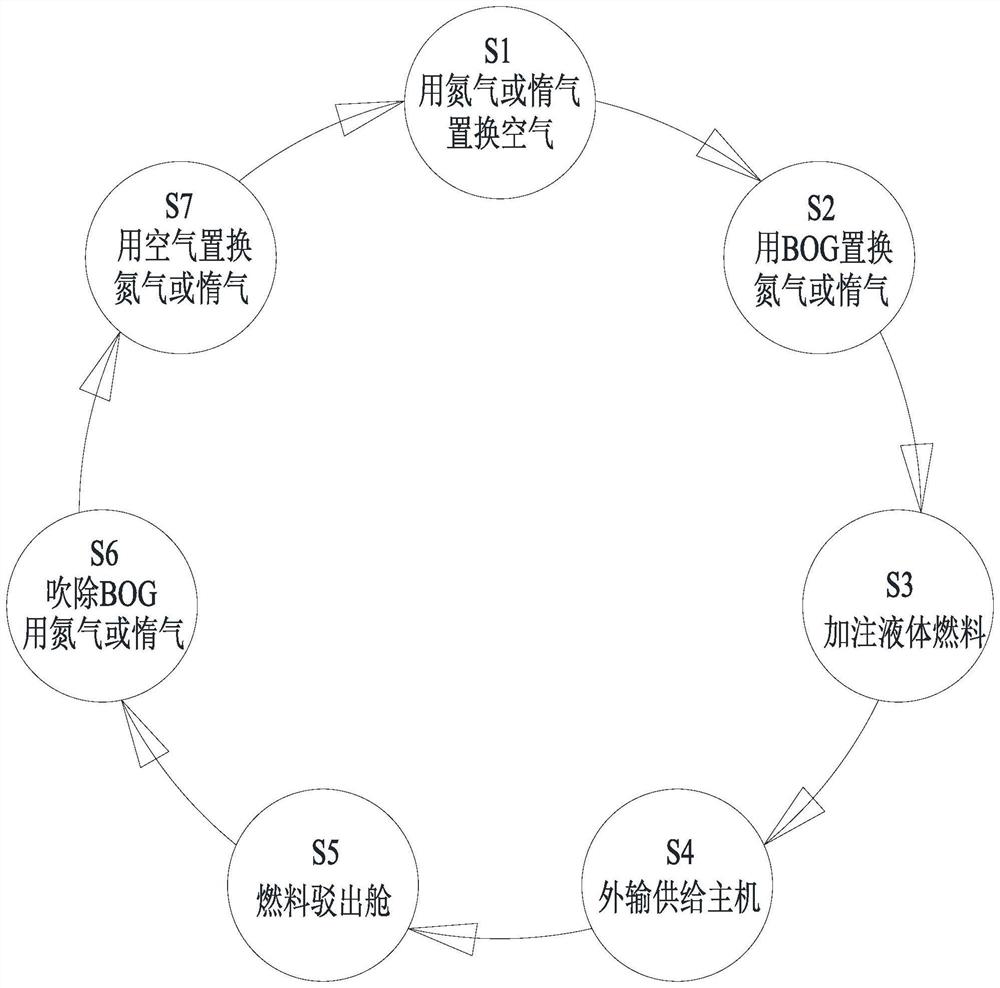

[0055] The present invention is aimed at the cargo tank 1 with a volume of ≤1500m3 and a working pressure of ≥4barg. Figure 1 to Figure 3 As shown, its control method is:

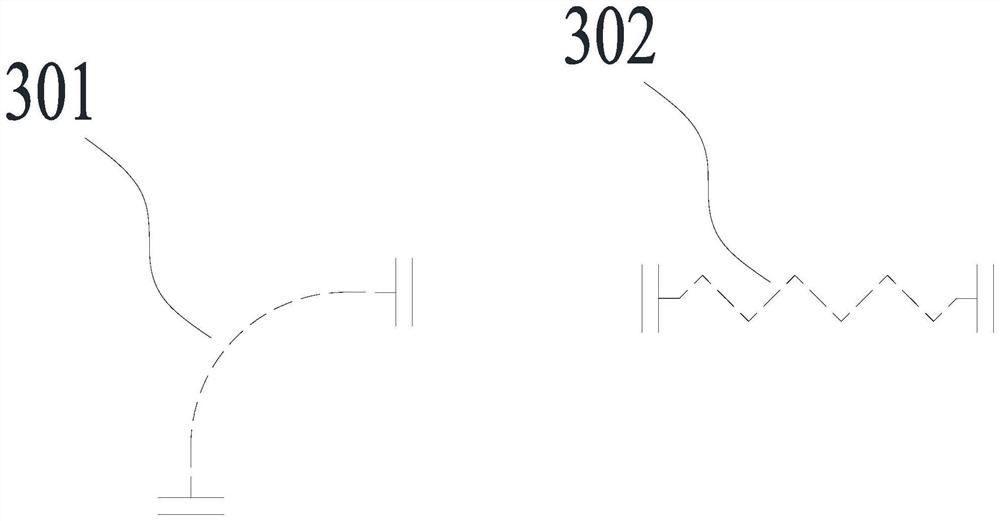

[0056] S1: Before filling tank 1, replace the air in the tank with nitrogen or inert gas. Such as nitrogen, install the detachable straight pipe 302 to connect the third nozzle 30 and the fourth nozzle 40. The nitrogen source starts from the seventh pipeline 207 and enters the cargo tank 1 through the seventh control valve 807 and the third pipeline 203. For purging, the displaced air is connected through the nozzle of the bilge nozzle assembly 401, the second pipeline 202, the sixth control valve 806, the tenth pipeline 210, the first nozzle 10 and the second nozzle 20 (can be installed by Remove the straight pipe 302), and then discharge it to the vent mast 103 through the fourth pipeline 204, and the completion signal is: the low-level detector 200 detects that the oxygen concentration in the bilge is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com