Sliding plate chassis sealing structure

A sealing structure and chassis technology, applied in the directions of transportation and packaging, sustainable transportation, climate sustainability, etc., can solve the problems of low mileage, low space efficiency, high vehicle cost, etc., and achieve the effect of low cost and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below with reference to the accompanying drawings.

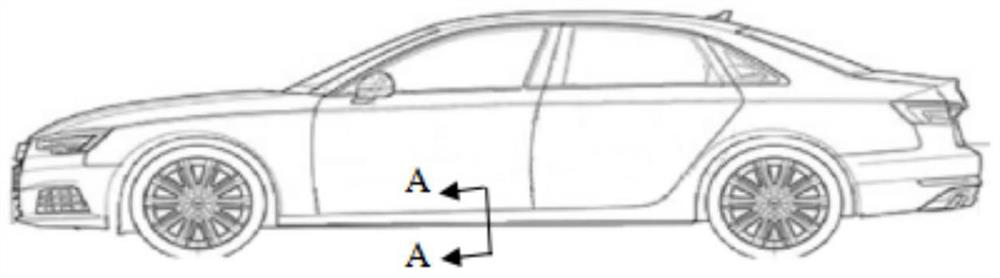

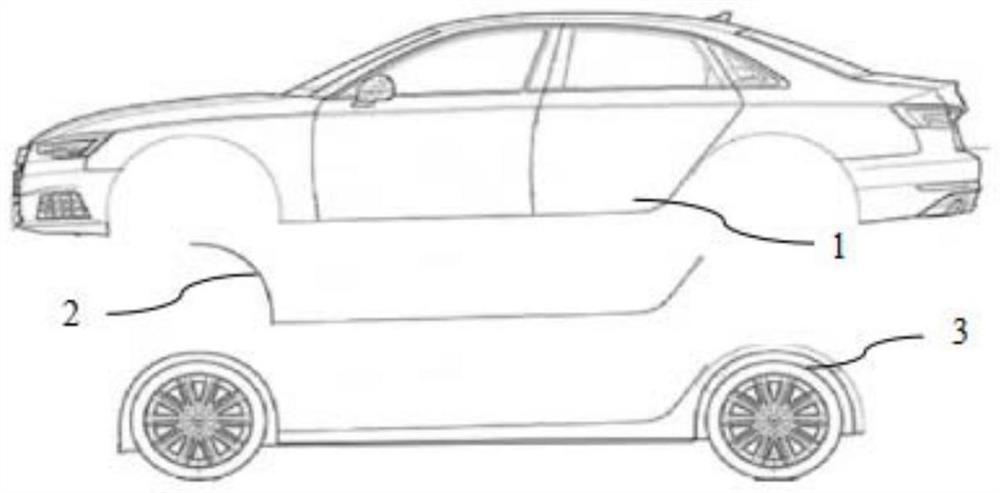

[0026] like figure 1 Shown is a perspective view of the entire vehicle, and the location of the schematic section A-A. figure 2 The exploded view of the whole vehicle is shown, showing the body 1, the skateboard chassis 3, and the skateboard sealing strip 2 arranged between the body 1 and the skateboard chassis 3.

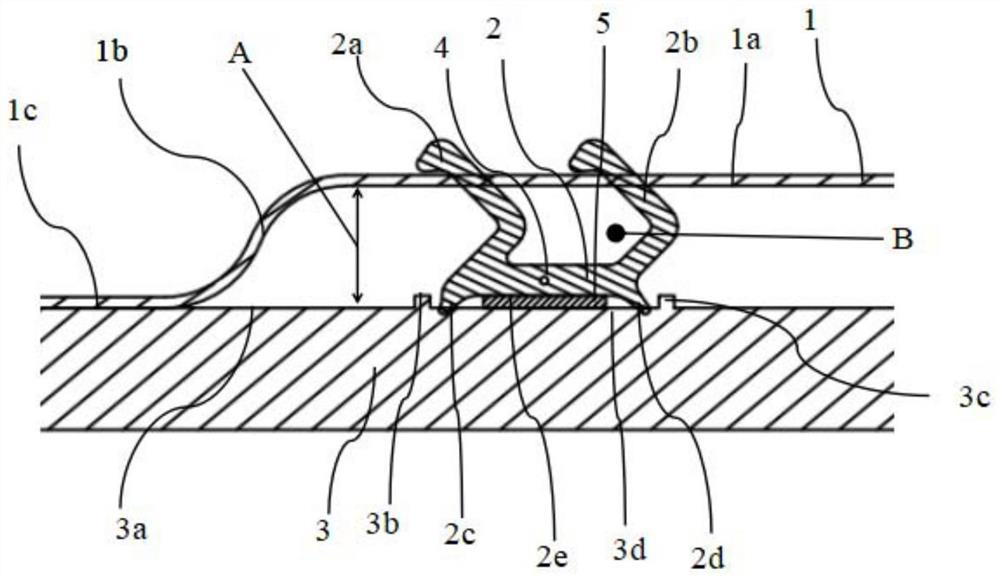

[0027] like image 3 As shown, a metal wire 4 is arranged in the sealing strip 2 of the skateboard chassis to prevent the sealing strip from shrinking in the length direction and increase the length stability of the sealing strip. Double-sided tape 5 is attached to the mounting surface 2e of the sealing strip of the skateboard chassis, and the double-sided tape 5 is attached to the mounting surface 3d of the sealing strip of the skateboard chassis. The skateboard chassis weather strip mounting surface 3d is disposed between the raised features 3b, 3c of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com