Trunk tool box, trunk assembly and vehicle

A technology for luggage and tool boxes, which is applied in vehicle parts, sustainable manufacturing/processing, climate sustainability, etc., can solve the problems of tool box compression deformation, inconvenient maintenance, and poor practicability, so as to meet the needs of use and prolong the use Longevity and the effect of improving the supporting force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

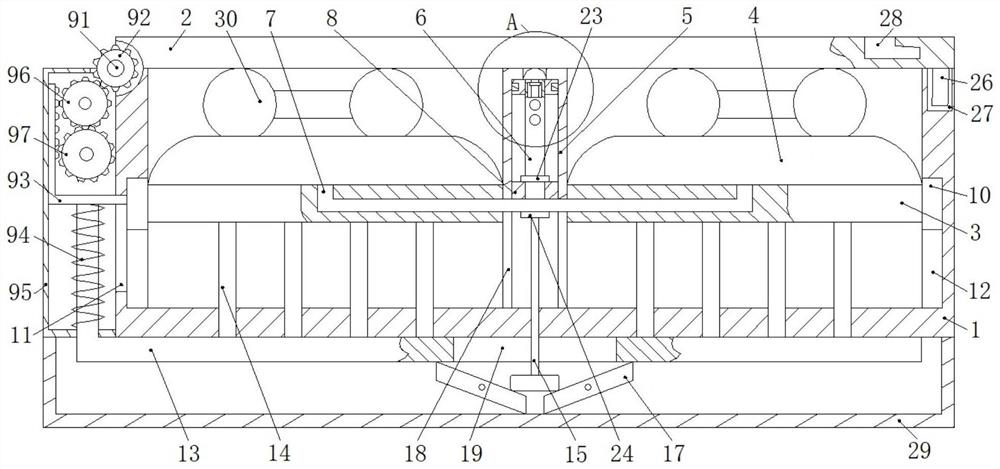

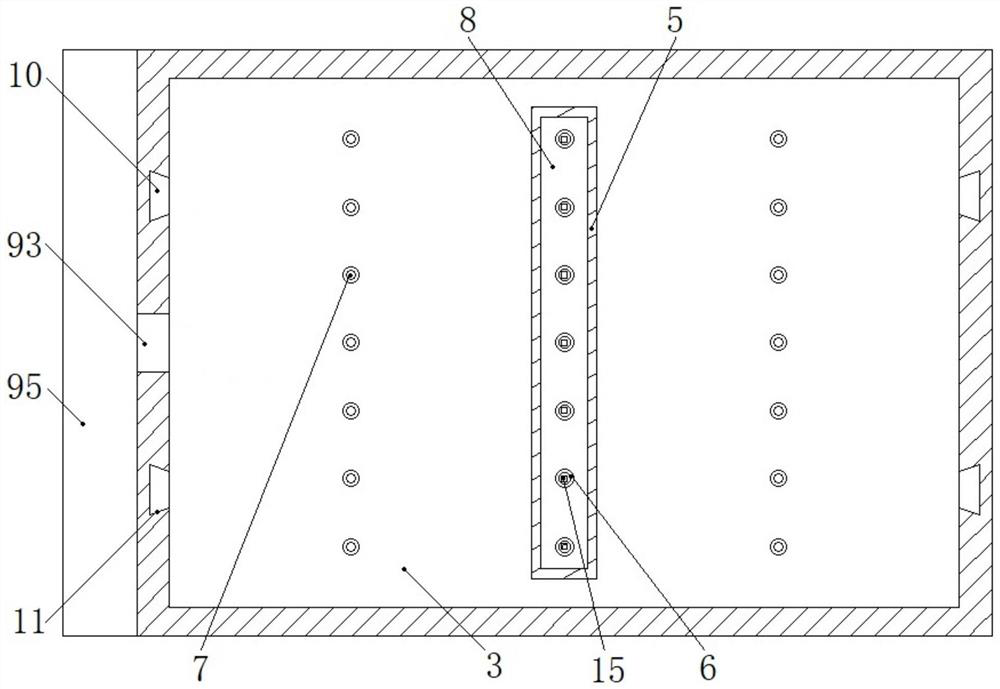

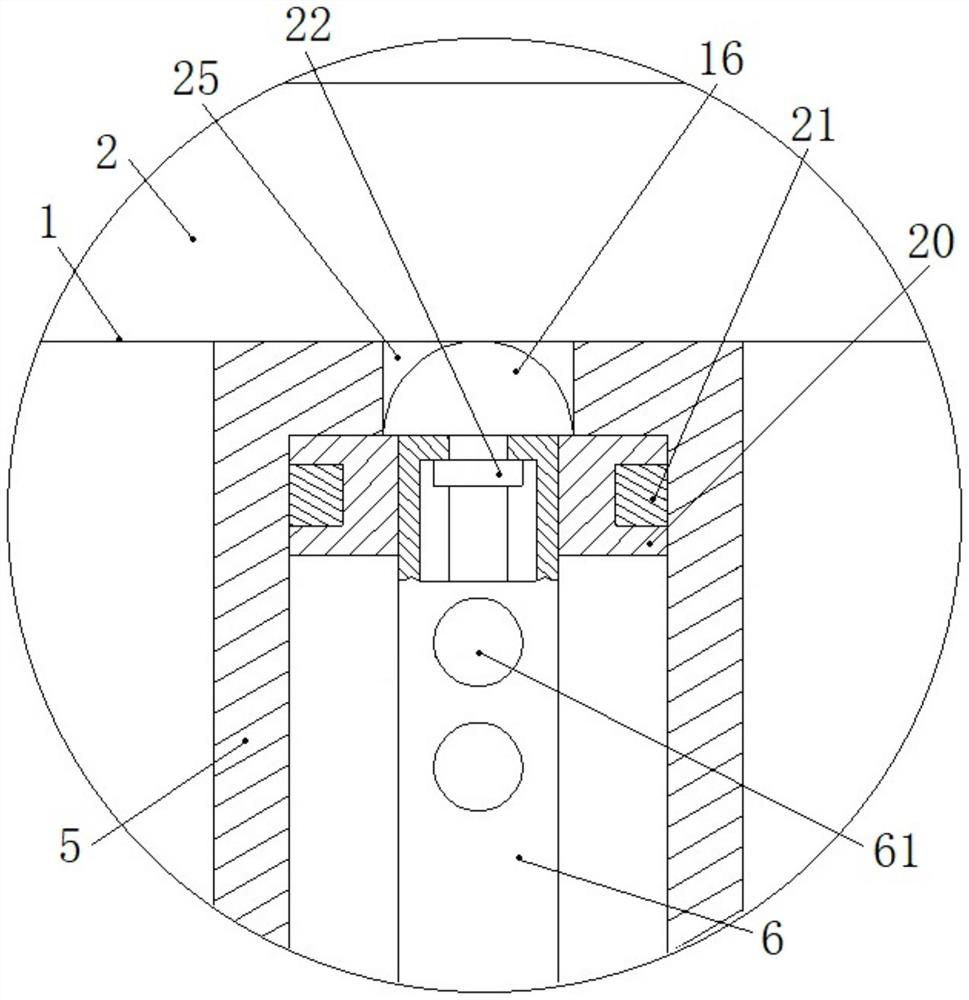

[0028] As a preferred embodiment of the present invention, one side of the cover plate 2 is hingedly fixed with the upper end of the box body 1 through the rotating shaft 91, and the other side is fixed with a positioning member 26 adapted to the positioning groove 27 on the box body 1, The assembly accuracy between the cover plate 2 and the box body 1 is guaranteed. In order to improve the matching relationship between the positioning member 26 and the positioning groove 27, a U-shaped rubber is fixed in the positioning groove 27. On the one hand, the U-shaped rubber plays a guiding role, so that the positioning member 26 can be smoothly inserted into the positioning groove 27. On the other hand, the U-shaped rubber is deformed under pressure after the positioning member 26 is inserted, and fills the positioning groove, thereby preventing the positioning member 26 from shaking.

[0029] A gear 92 is fixed on the rotating shaft 91 , and a rack 93 meshing with the gear 92 is pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com