Coaxial character rolling device of radio frequency connector

A radio frequency connector, coaxial technology, used in decorative arts, embossed decorative parts, etc., can solve the problems of uneven pressing force, waste of manpower and time, uneven font lines, etc., to ensure structural stability and improve uniformity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The following is a further detailed description of the present application.

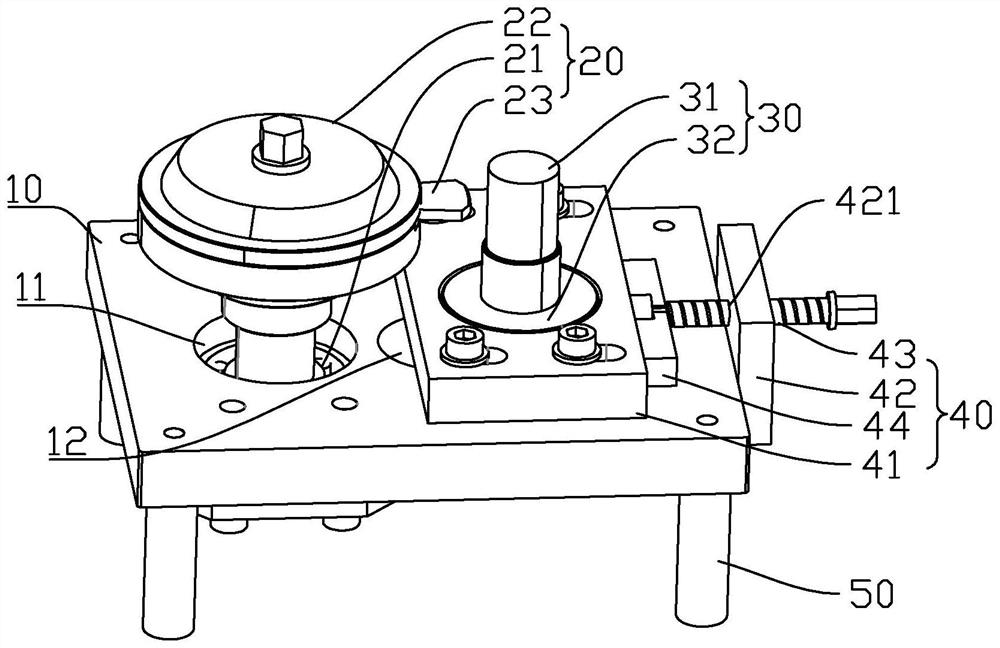

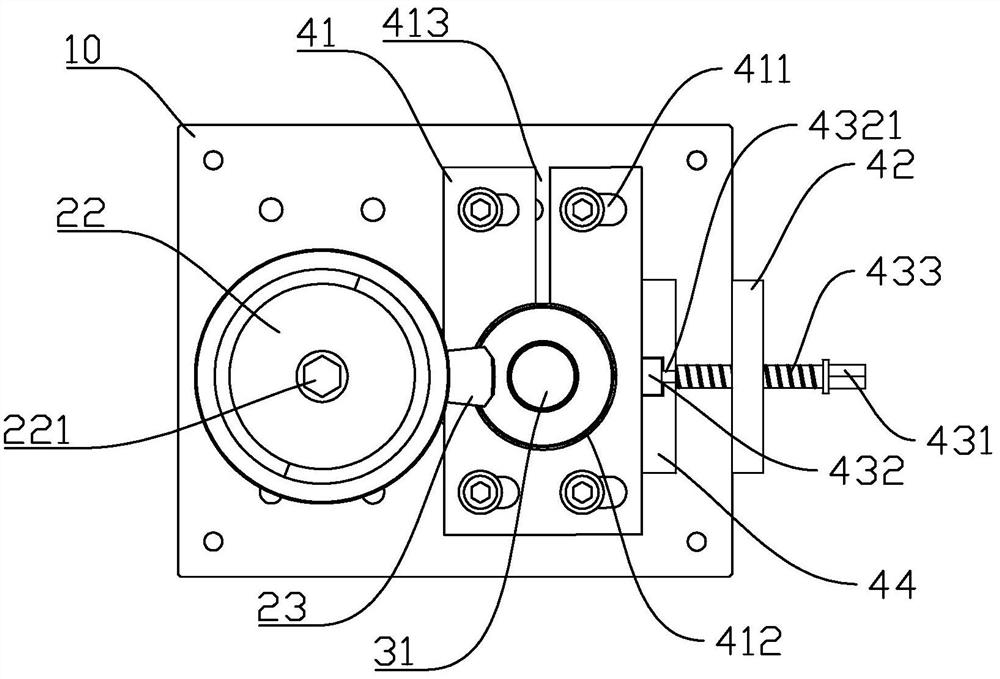

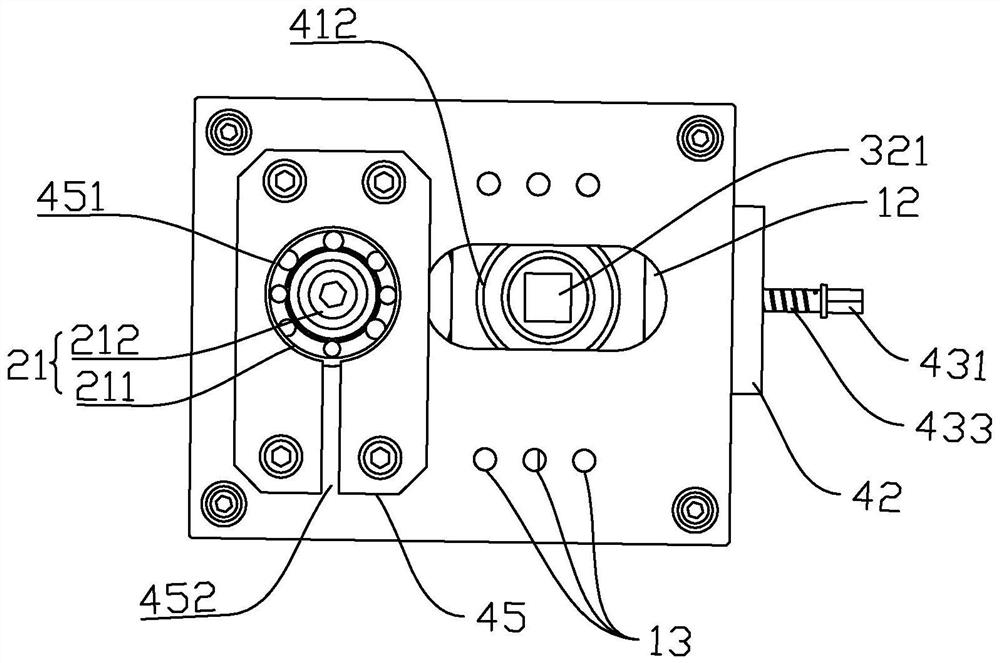

[0036] The embodiment of the present application discloses a coaxial roll-type device for a radio frequency connector. refer to figure 1 , the coaxial roller character device of the radio frequency connector includes: the machine 10, the printing press rotating shaft assembly 20 and the fixed assembly 30, the printing press rotating shaft assembly 20 and the fixed assembly 30 are relatively arranged on both sides of the table surface of the machine 10, and the printing press rotates The shaft assembly 20 rotates relative to the fixed assembly 30, and one end of the fixed assembly 30 is used to insert the workpiece to be processed for assembling the coaxial radio frequency connector. Of course, in another embodiment, the workpiece to be processed is not limited to the coaxial assembly part of the RF connector, but can also be other components that need to be formed.

[0037] Wherein, the mach...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com