Distributed multi-stage precise coal blending and mixing coal bunker based on mixing of multiple coal formulas

A distributed, coal technology, applied in mixers, solid and solid mixing, mixers with rotary stirring devices, etc. Easy to stick to each other and other problems, to ensure orderly operation, ensure intelligent operation, and prevent mutual adhesion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

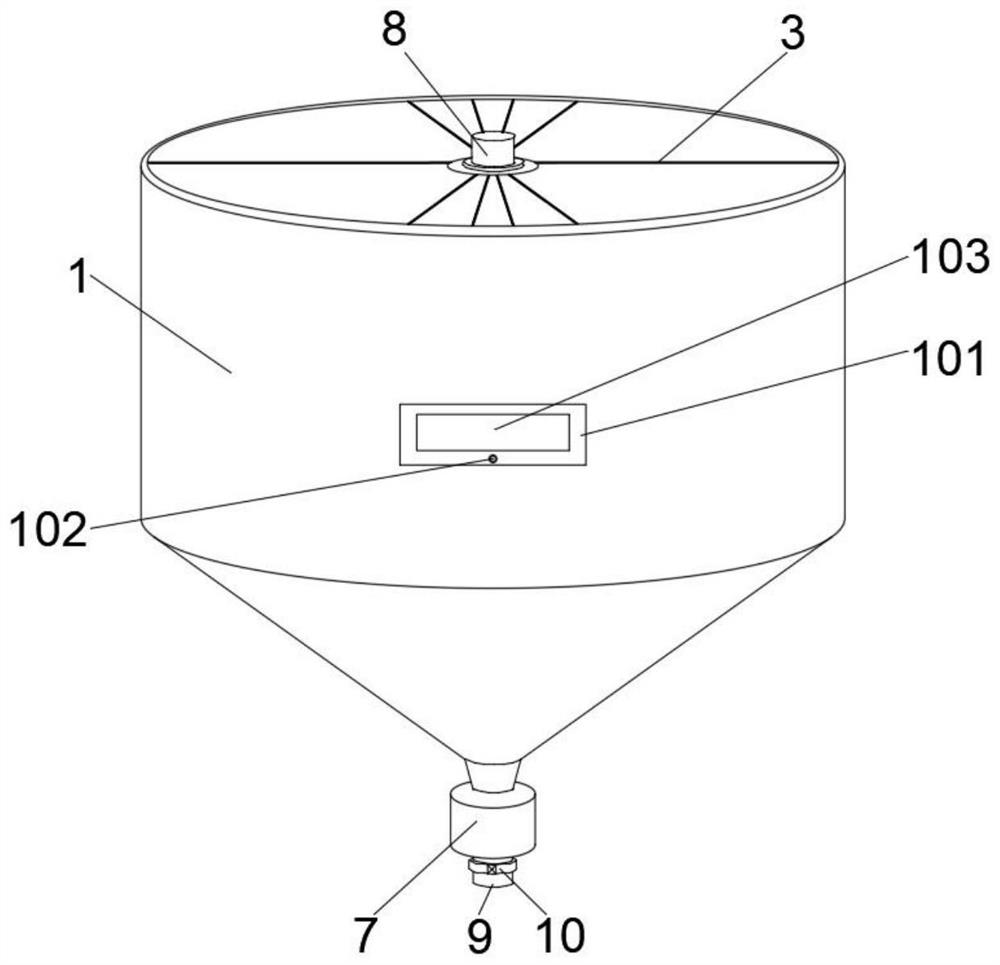

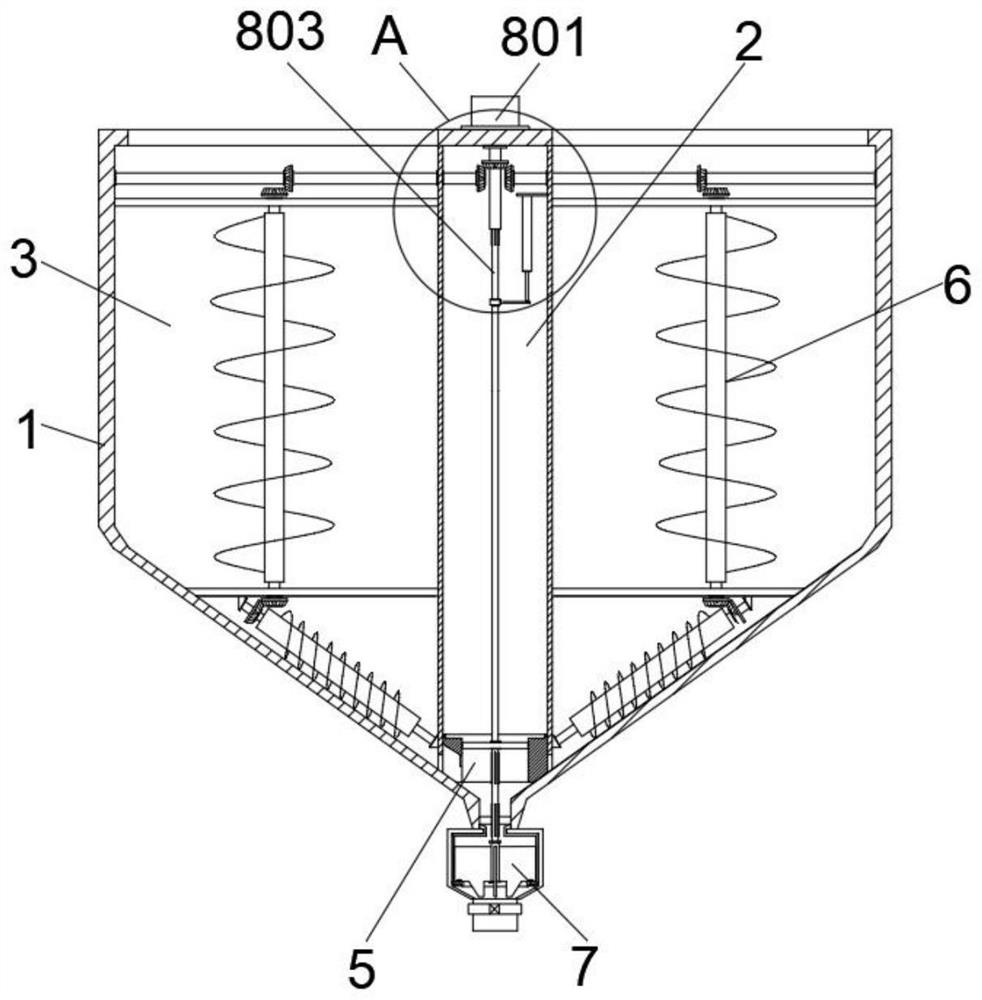

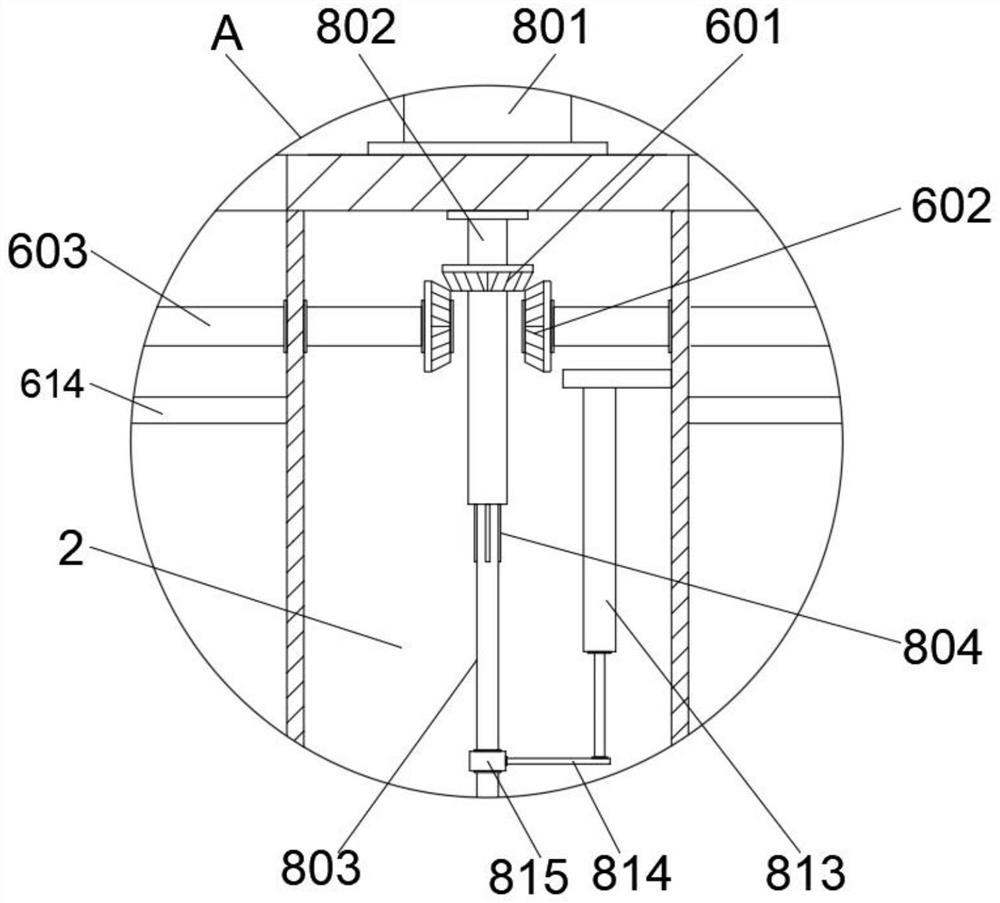

[0038] like Figure 1-7 As shown, the distributed multi-stage precise coal blending mixed coal bunker based on the mixing of various coal formulations includes an outer ring coal shell 1, the bottom of the outer ring coal shell 1 shrinks inwardly into a V shape, and the outer ring coal shell 1 There is an inner ring coal hull 2, a partition partition 3 is arranged between the inner ring coal hull 2 and the outer ring coal hull 1, and the bottom end of the inner ring coal hull 2 is fixedly connected with the bottom inner wall of the outer ring coal hull 1, and the partition The two sides of the partition plate 3 are respectively fixedly connected with the outer wall of the inner ring coal hull 2 and the inner wall of the outer ring coal hull 1, and there are multiple partition partition plates 3, and the center of the partition partition plate 3 is the center of the inner ring coal hull 2. And distributed in a circular array, two partitions and 3 gaps are arranged to form...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com