Adjustable anti-oscillation and anti-oscillation device for transporting fluidized cargos in ship cargo hold

A transport flow, adjustable technology, which is applied in the field of anti-sloshing and swaying devices for the transport of fluidized cargo in adjustable ship cargo holds, can solve the problems of diversion treatment, poor safety, hull damage, etc., to avoid turbulence and ensure stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solutions in the embodiments of the present invention will be clearly and completely described below with reference to the accompanying drawings in the embodiments of the present invention.

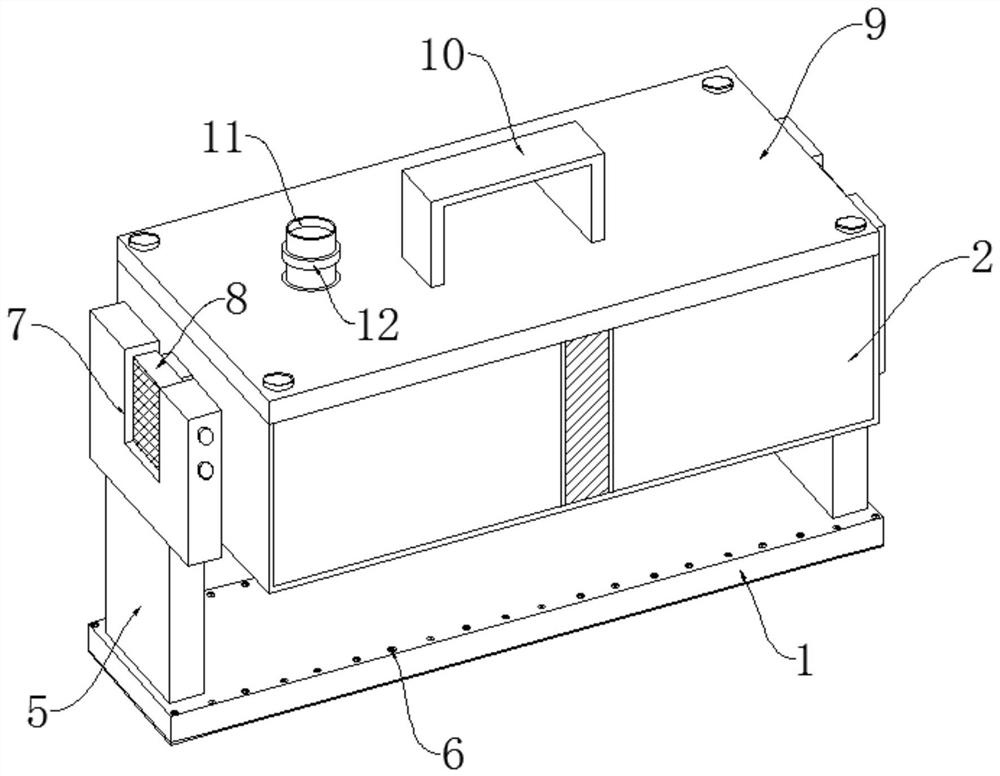

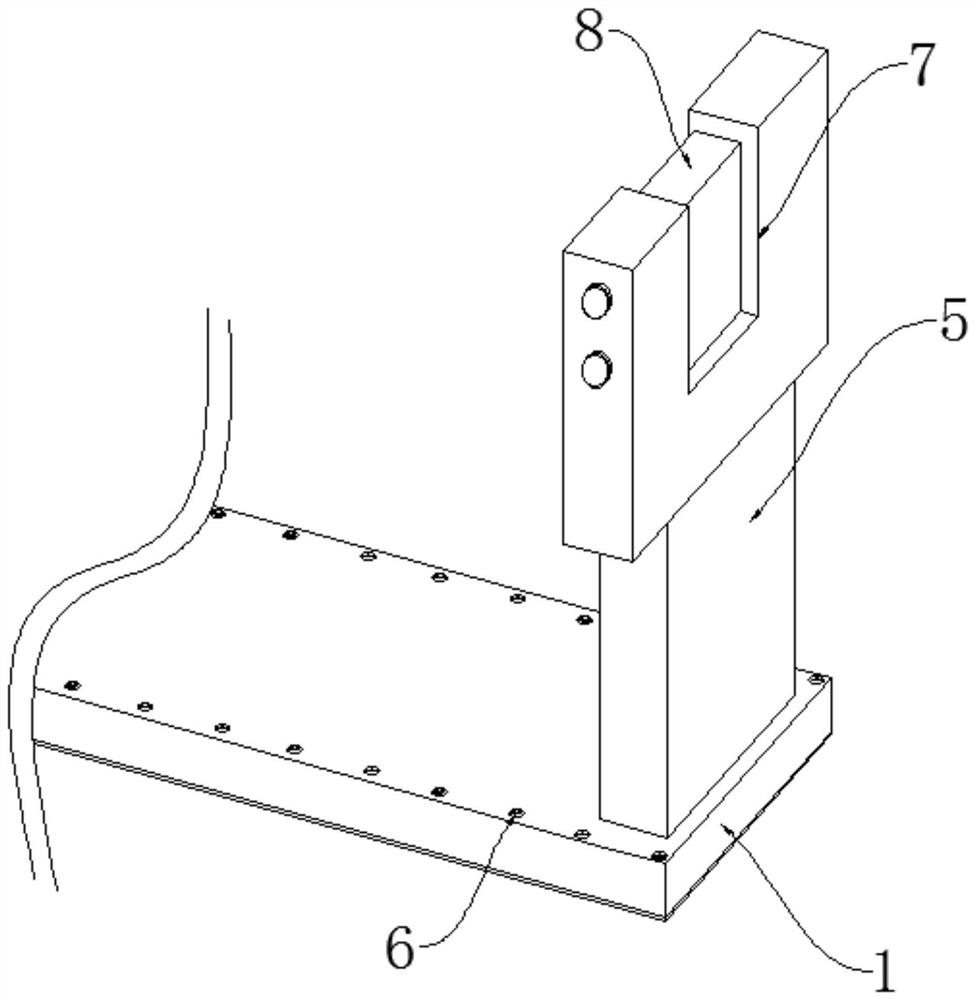

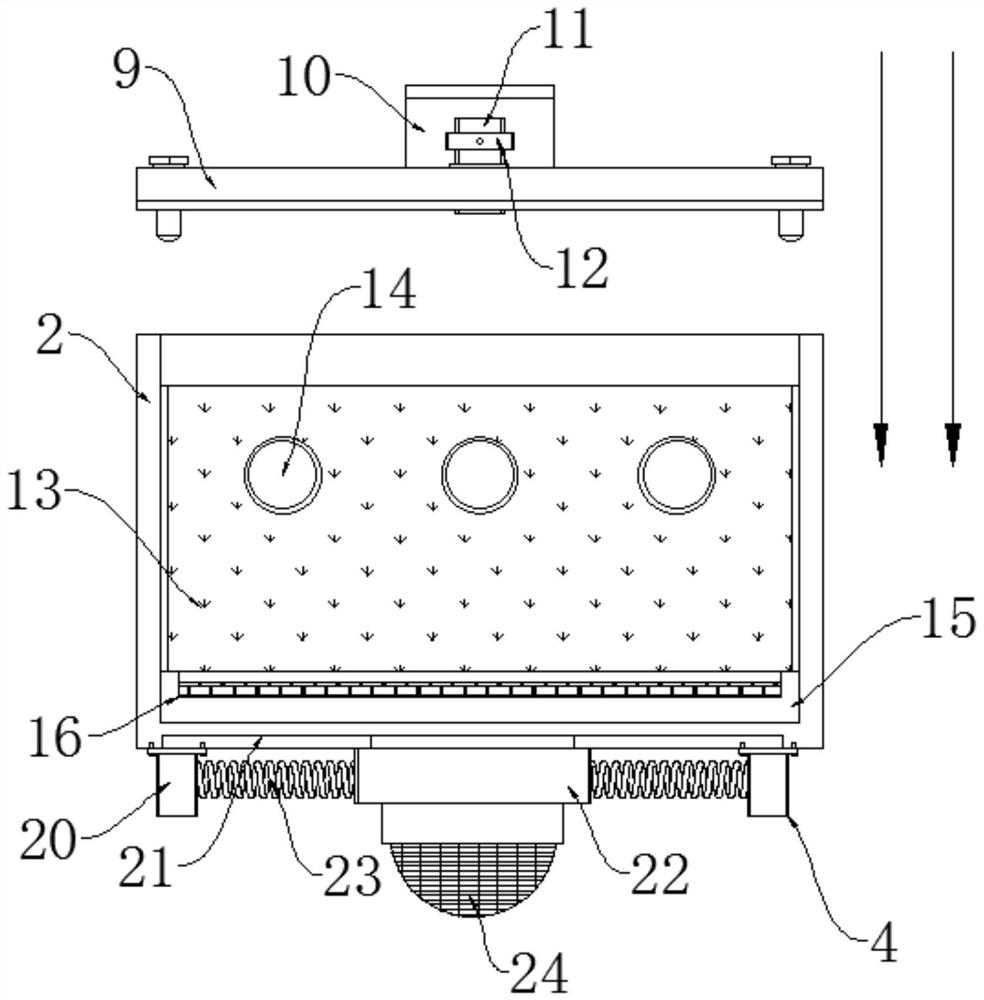

[0022] like Figure 1-5 As shown, the present invention provides a technical solution: an adjustable anti-sloshing device for transporting fluidized cargo in a ship's cargo hold, comprising a base 1, a storage box 2 with an opening on the top, an internal protection component 3 and a shock-absorbing component 4, Vertical plates 5 are welded in parallel on both sides of the upper surface of the base 1, the storage box 2 is installed between the vertical plates 5, the internal protection component 3 is installed in the storage box 2, and the shock absorption component 4 is matched and installed in The lower surface of the storage box 2.

[0023] In this embodiment, specifically: the lower surface of the base 1 is provided with an anti-skid pad, and a plurality of sets ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com