Dimming assembly, preparation method thereof and vehicle

A component and dimming technology, applied in vehicle parts, chemical instruments and methods, optics, etc., can solve problems such as unevenness and defective appearance of dimming glass, and achieve the effect of no Mura, avoiding bad appearance and good appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

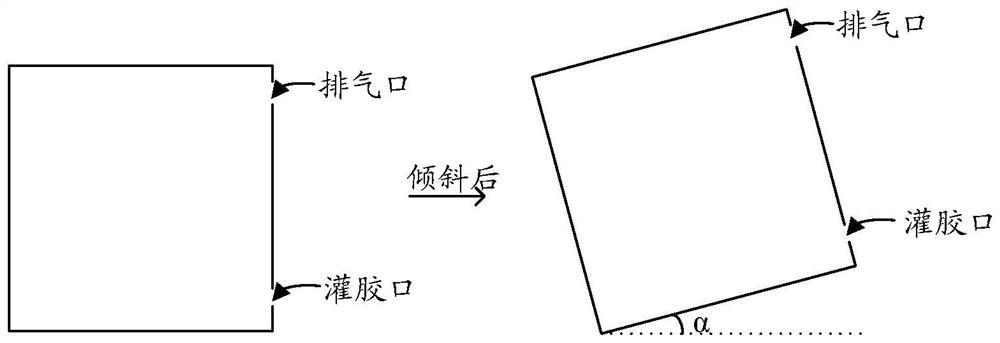

[0059] A second aspect of the present invention provides a method for preparing a dimming component in an embodiment, which is a method for preparing the dimming component in the above-mentioned embodiment, including the following steps:

[0060] Step S110: Laminate the first light-transmitting plate, the first adhesive layer and the light-adjusting film in sequence, and then perform lamination.

[0061] Wherein, the material of the first adhesive layer is non-liquid optical glue before preparing the dimming component. For example, before preparing the dimming component, the material of the first adhesive layer may be solid or solidified optical adhesive OCA, or may be polymer adhesive. In one embodiment, the material of the first adhesive layer is selected from one of PVB and EVA before preparing the light-adjusting component, and the edge of the light-adjusting film is opposite to the first light-transmitting plate and the inside of the first adhesive layer. shrink.

[006...

Embodiment 1

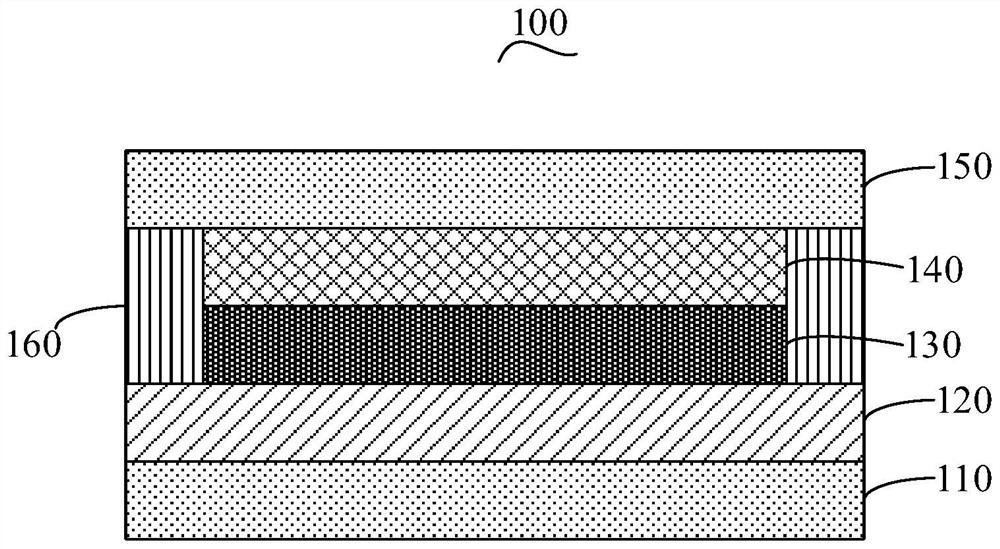

[0088] see figure 2 The present embodiment provides a dimming component, specifically a dimming glass 100, the dimming glass 100 includes: a first light-transmitting plate 110, a first adhesive layer 120, a dimming film 130, a second light-transmitting plate 110, a first adhesive layer 120, a dimming film 130, a second The adhesive layer 140 and the second light-transmitting plate 150 . The first light-transmitting plate 110 and the second light-transmitting plate 150 are both hyperbolic glass (the main curvature is: 2293-4900 mm, the secondary curvature is 4887-475778 mm, and the thickness is 2.1 mm). The first adhesive layer 120 is a PVB film with a thickness of 0.38 mm. Before preparing the dimming component, the material of the second adhesive layer 140 is liquid optical glue (specifically, US108 liquid optical glue), and the thickness is 0.4 mm. The dimming film 130 is an LC dimming film. The light-adjusting film 130 and the second adhesive layer 140 are retracted rel...

Embodiment 2

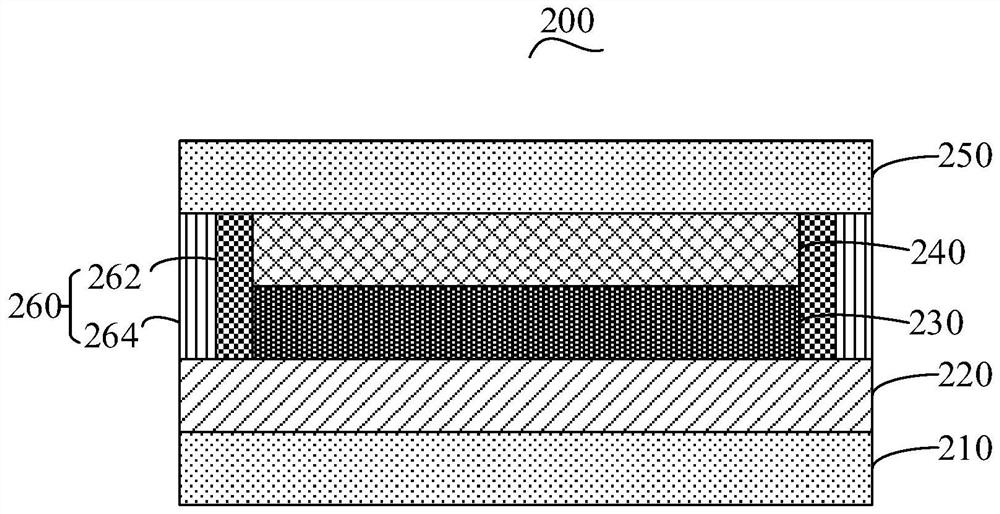

[0096] see image 3 The present embodiment provides a dimming component, specifically a dimming glass 200. The dimming glass 200 includes: a first light-transmitting plate 210, a first adhesive layer 220, a dimming film 230, a second light-transmitting plate 210, a first adhesive layer 220, a second The adhesive layer 240 and the second light-transmitting plate 250 . The first light-transmitting plate 210 and the second light-transmitting plate 250 are both hyperbolic glass (the main curvature is: 2293-4900 mm, the secondary curvature is 4887-475778 mm, and the thickness is 2.1 mm). The first adhesive layer 220 is a PVB film with a thickness of 0.38 mm. Before preparing the dimming component, the second adhesive layer 240 is made of liquid optical glue (specifically, US108 liquid optical glue), and the thickness is 0.4 mm. The dimming film 230 is an LC dimming film. The light-adjusting film 230 and the second adhesive layer 240 are retracted relative to the first light-tran...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com