Built-in heat dissipation fan structure for cascade type power electronic device

A technology of power electronic devices and heat dissipation fans, which is applied in the cooling/ventilation of substation/switchgear, substation/distribution device shell, substation/switch arrangement details, etc. Or problems such as large container volume and large overall size of the device cabinet, to achieve the effect of improving power density and space utilization, neat and generous appearance, and effective and reasonable noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below with reference to the accompanying drawings and embodiments.

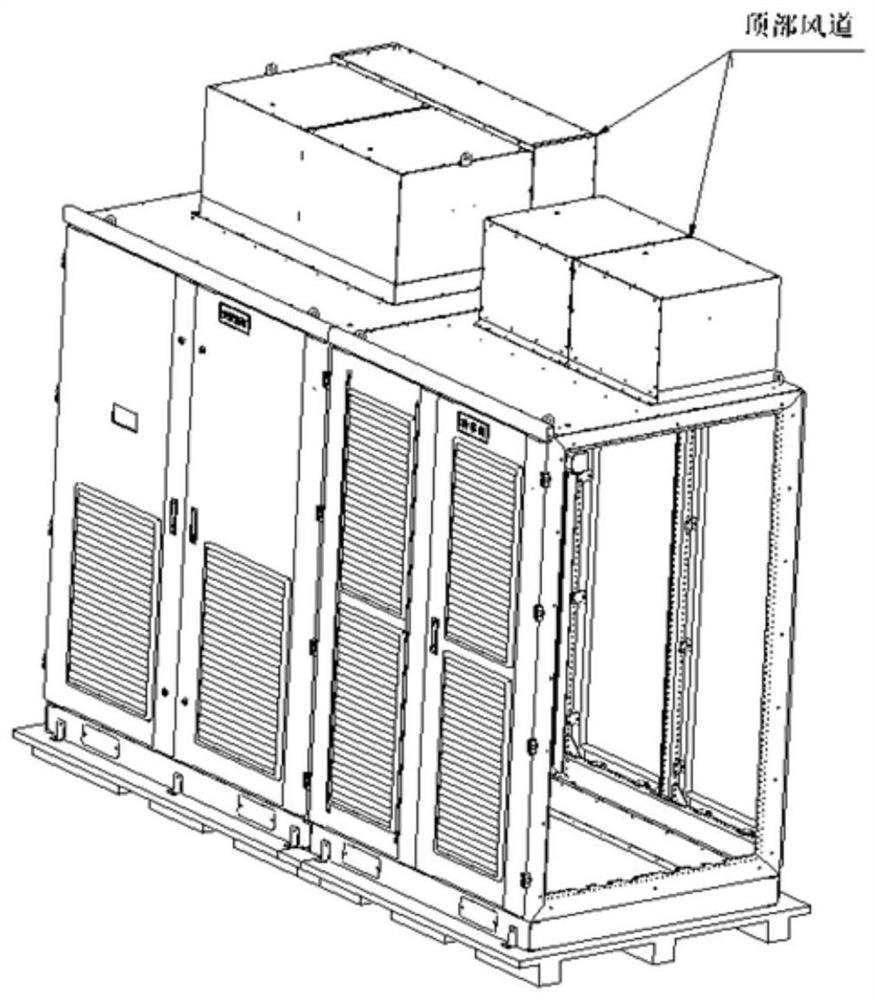

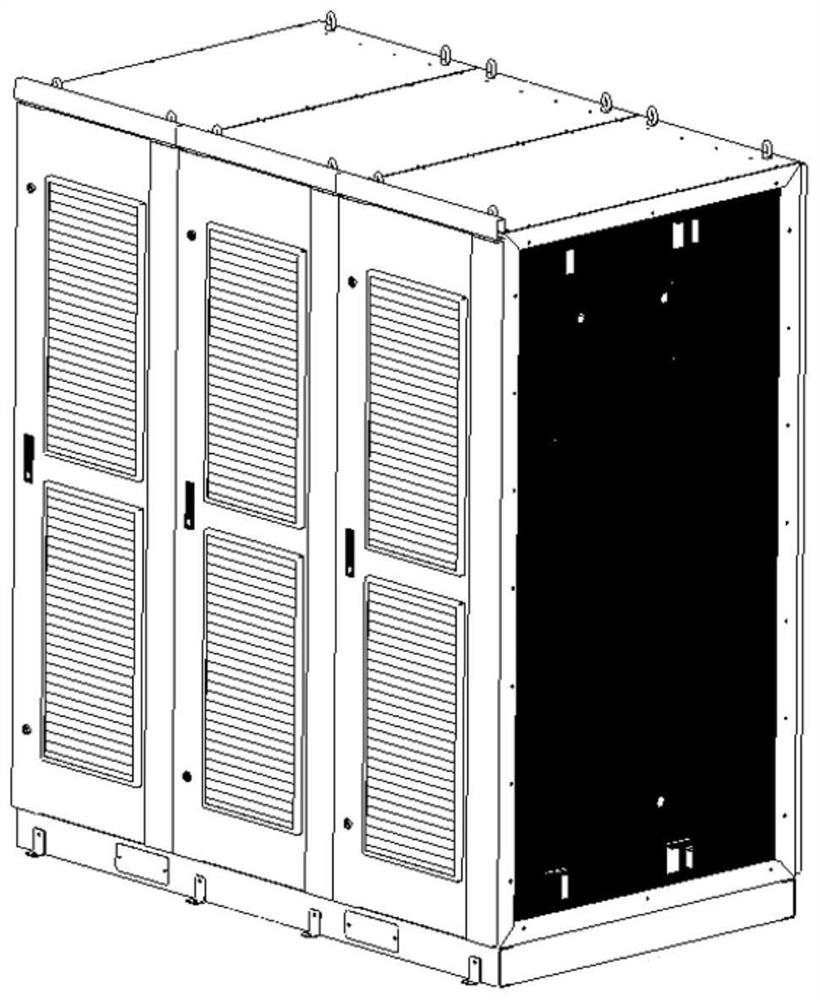

[0025] like Figure 2 to Figure 9 As shown in the figure, a built-in cooling fan structure for a cascaded power electronic device includes a built-in fan cabinet 1 of the cascaded power electronic device, a rear door panel 2 of the cascaded power electronic device cabinet, and a cascaded power electronic device. The honeycomb air outlet on the rear door panel of the electronic device 3, the cooling fan installation cover 4, the cooling fan 5, the cooling fan wind guide ring 6, the cooling air duct 7, the cooling air duct rear panel 8, the cooling air duct upper panel 9, Fastening bolt holes 10.

[0026] The inside of the built-in fan cabinet 1 of the cascaded power electronic device is provided with a plurality of cooling air cavities, the top of each cooling air cavity is provided with a cooling fan 5, and the rear is provided with a cooling air duct re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com