HMI master control system using additive and subtractive all-in-one machine and control method

A main control system, adding and subtracting material technology, applied in the direction of general control system, computer control, control/regulation system, etc., can solve the problems of long product development cycle, many processing links, long cycle of parts forming process, etc., to save programming and simulation analysis time, the improvement of internal structure organization performance, and the effect of shortening the development cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] The present invention will be further described below in conjunction with the accompanying drawings. Obviously, the described embodiments are some, but not all, embodiments of the present invention. Based on the embodiments of the present invention, all other embodiments obtained by those of ordinary skill in the art without creative efforts shall fall within the protection scope of the present invention.

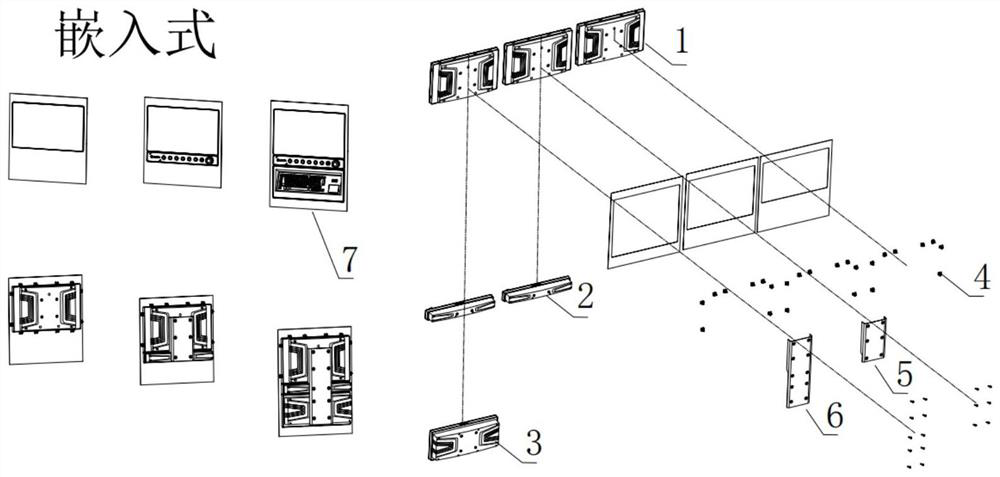

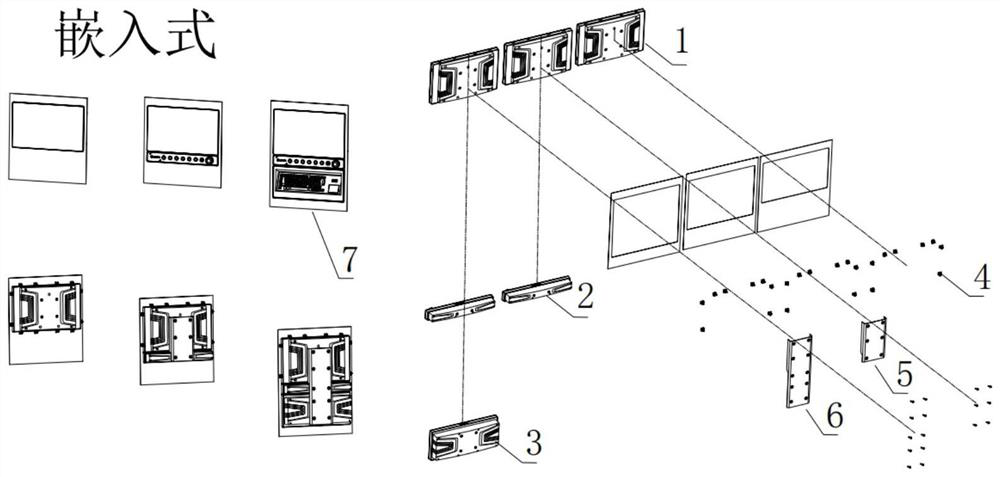

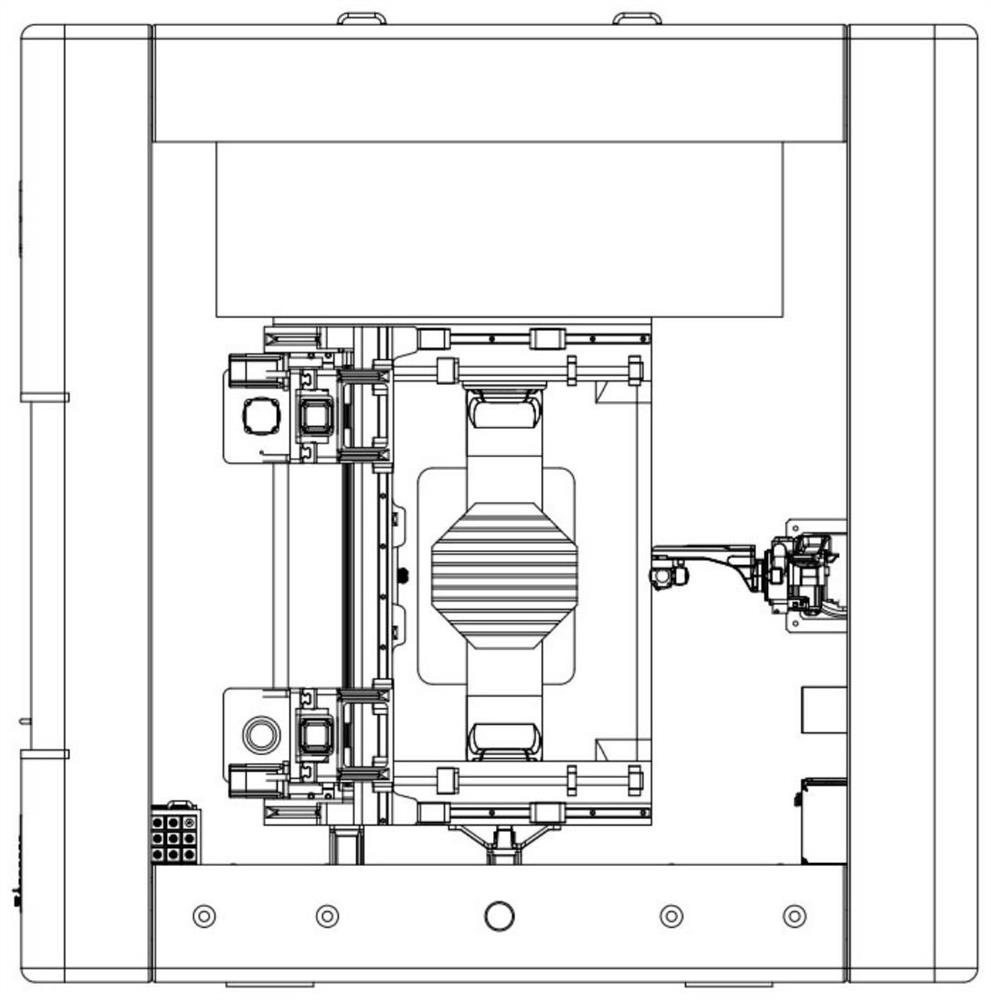

[0060] The invention aims to provide an integrated arc additive system, a five-axis machining center subtraction system, a Haoken precision subtraction system, and an industrial camera vision system that integrates the HMI main control equipment components and systems to command the entire machine to operate uniformly. There is no need to open molds, reduce the processing links of existing precision metal parts on the market, and shorten the development cycle of metal parts. The elimination rate of residual stress of metal parts reaches 80-100%, and it can also gener...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com