Electrode sealing device

A sealing device and electrode technology, which is applied in the field of cabin penetration sealing, can solve the problems of affecting the experimental process, high cost, and experimental failure, and achieve the effect of simple replacement operation, simple structure, and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

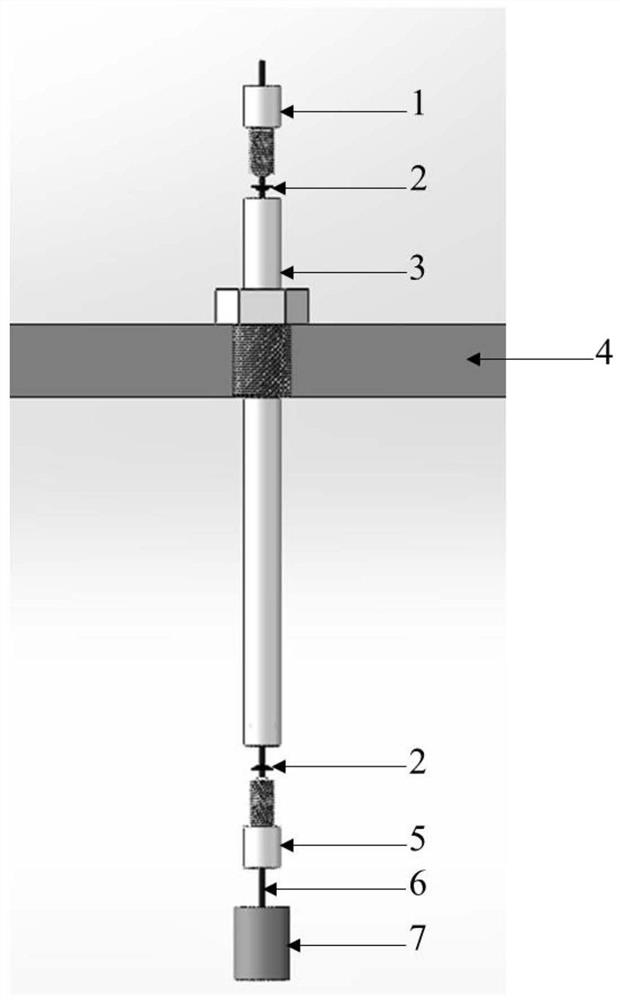

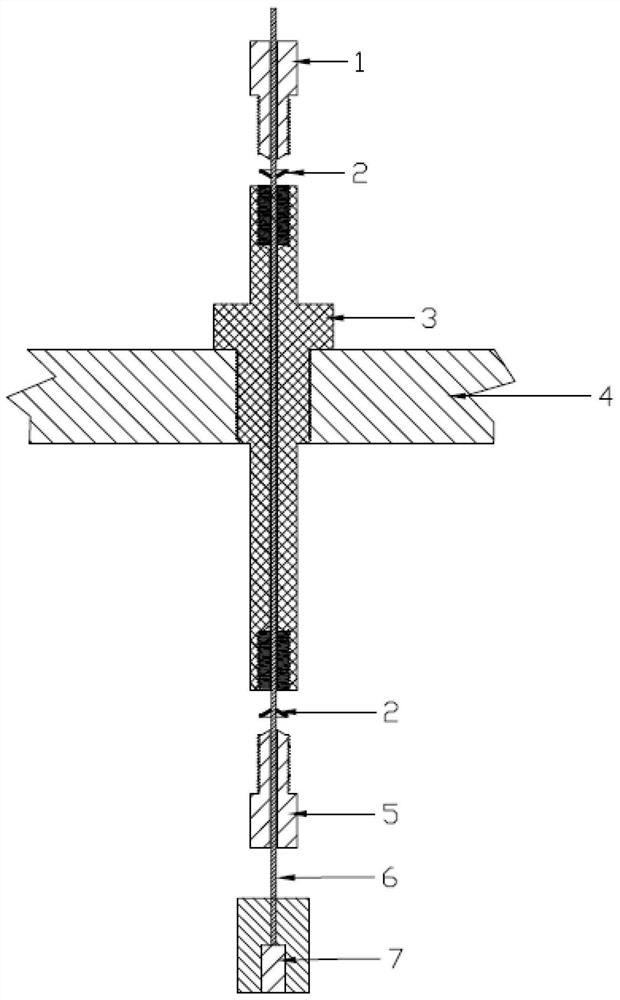

[0012] The main structure of the electrode sealing device involved in this embodiment includes an upper compression coil 1 , a sealing member 2 , a cabin penetration pipe 3 , a lower compression coil 5 , a wire 6 , and an electrode 7 ; the pressure kettle 4 is provided with a penetration chamber. Pipe fitting 3, a wire 6 is threaded through the cabin fitting 3, the upper end of the wire 6 is sleeved with an upper compression coil 1, the lower end of the wire 6 is sleeved with a lower compression coil 5, and the wire 6 and the upper compression coil are sleeved A seal 2 is arranged between 1 and the lower compression solenoid 5. The top end of the wire 6 extends out of the upper compression coil 1, and the bottom end of the wire 6 extends out of the lower compression coil 5 and is connected to the electrode 7.

[0013] The sealing member 2 involved in this embodiment is a hollow conical sealing ring; the gap between the inner diameter of the cabin-penetrating pipe member 3 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com