Purification device with oil stain self-adsorption function for oil fume waste gas treatment

A technology for waste gas treatment and purification devices, which is applied in the fields of oil fume removal, application, household stoves, etc., can solve the problems of clogging of purification devices, troublesome disassembly operations, and difficult to clean up, and achieves the effect of preventing clogging, reducing maintenance costs, and ensuring normal use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

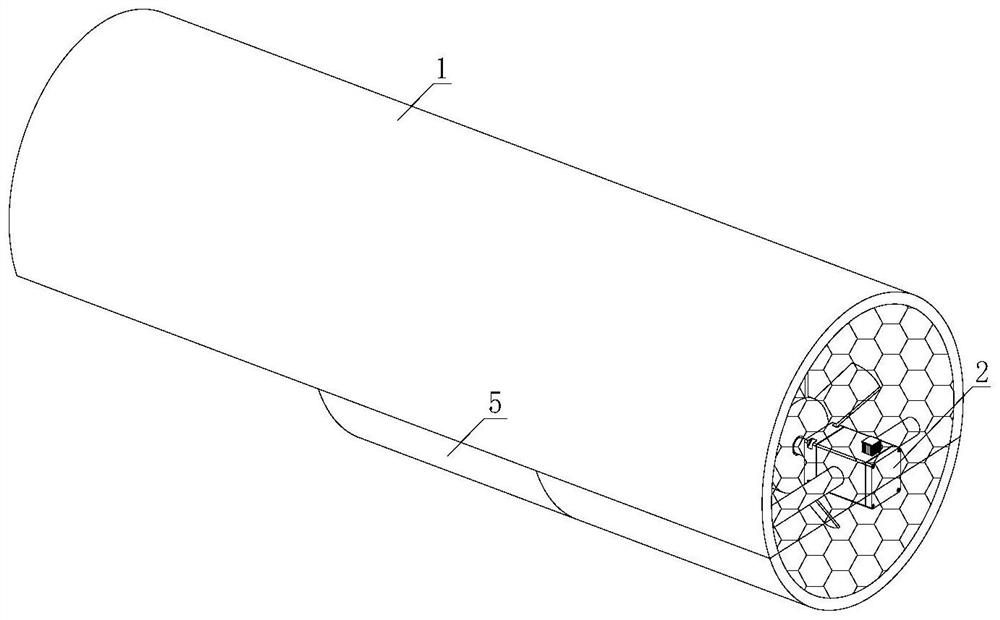

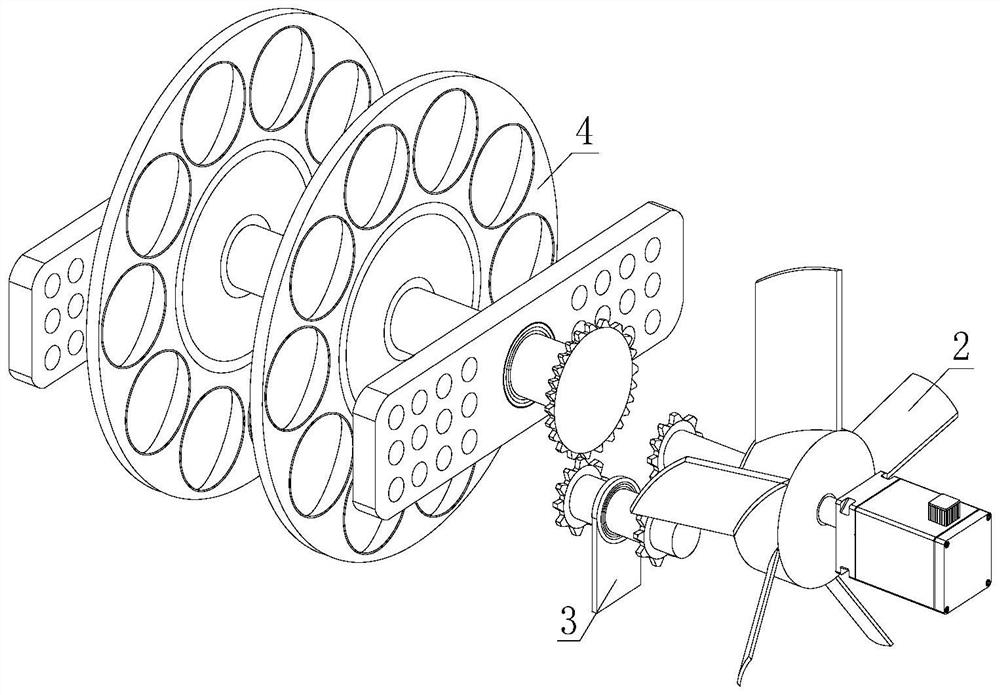

[0030] see Figure 1-2 , A purification device with oil pollution self-adsorption for oil fume exhaust gas treatment, including equipment main pipe 1, driving mechanism 2, transmission mechanism 3, adsorption filtering mechanism 4 and cleaning mechanism 5, and the driving mechanism 2 is fixedly arranged at the air outlet of the equipment main pipe 1 , the lower end of the transmission mechanism 3 is fixedly connected with the inner lower end of the equipment main pipe 1, and one end of the upper end is engaged with the drive mechanism 2, and the other end of the upper end is engaged with one end of the adsorption filter mechanism 4, and the two ends of the adsorption filter mechanism 4 are fixedly set Inside the equipment main pipe 1 , the cleaning mechanism 5 is located at the lower end of the adsorption filtering mechanism 4 and is arranged at the lower end of the equipment main pipe 1 .

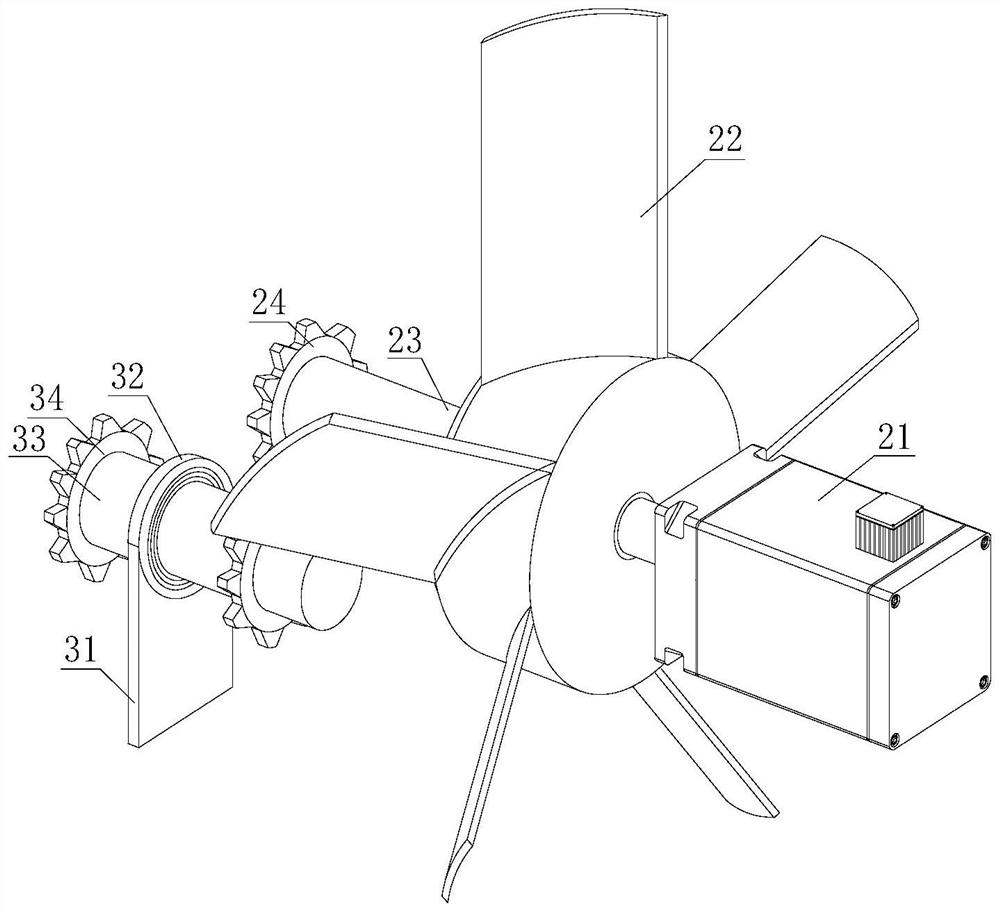

[0031] see image 3 , a purification device with oil self-adsorption for oil fume and...

Embodiment 2

[0037] see Figure 1-2 , A purification device with oil pollution self-adsorption for oil fume exhaust gas treatment, including equipment main pipe 1, driving mechanism 2, transmission mechanism 3, adsorption filtering mechanism 4 and cleaning mechanism 5, and the driving mechanism 2 is fixedly arranged at the air outlet of the equipment main pipe 1 , the lower end of the transmission mechanism 3 is fixedly connected with the inner lower end of the equipment main pipe 1, and one end of the upper end is engaged with the drive mechanism 2, and the other end of the upper end is engaged with one end of the adsorption filter mechanism 4, and the two ends of the adsorption filter mechanism 4 are fixedly set Inside the equipment main pipe 1 , the cleaning mechanism 5 is located at the lower end of the adsorption filtering mechanism 4 and is arranged at the lower end of the equipment main pipe 1 .

[0038] see image 3 , a purification device with oil self-adsorption for oil fume and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com