Adjustable composite damping rubber pad

A shock-absorbing rubber pad and adjustable technology, applied in the field of rubber pads, can solve the problems of inconvenient processing, limited rigidity range, different rigidity requirements, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

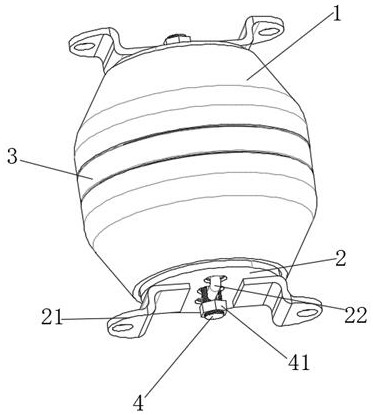

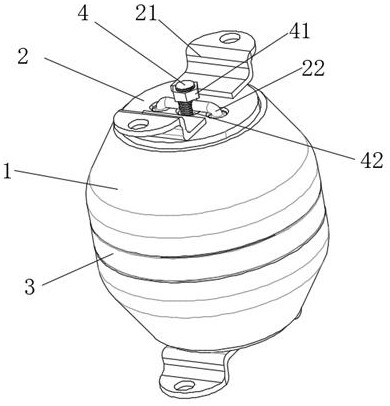

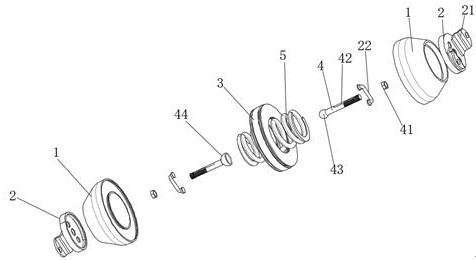

[0042] see Figure 1-9 , an adjustable compound shock-absorbing rubber pad, comprising two oppositely arranged rubber pads 1, a buffer device 3 is arranged between the two rubber pads 1, the buffer device 3 includes a flexible rubber sleeve 31, and the flexible rubber sleeve 31 is provided with Two groups of friction rings 32, the friction rings 32 are annular structures with an L-shaped cross-section, the two friction rings 32 are interlockingly arranged, and the sides away from the two friction rings 32 are respectively fixedly connected with the rubber pad 1, and the friction rings 32 A fixed magnetic ring 323 is provided on one side of the circular ring of the friction ring 32, and a cavity is provided on the other side of the circular ring of the friction ring 32. The sliding magnetic ring 33 is slidably connected in the cavity. The sliding magnetic ring 33 has the same magnetic properties as the fixed magnetic ring 323. A return spring 34 is sandwiched between the slidin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com