Arrangement structure for PHC tubular pile shear test

A technology for PHC pipe piles and layout structure, which is applied in the direction of applying stable shear force to test material strength, measuring devices, instruments, etc. interference, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with accompanying drawing.

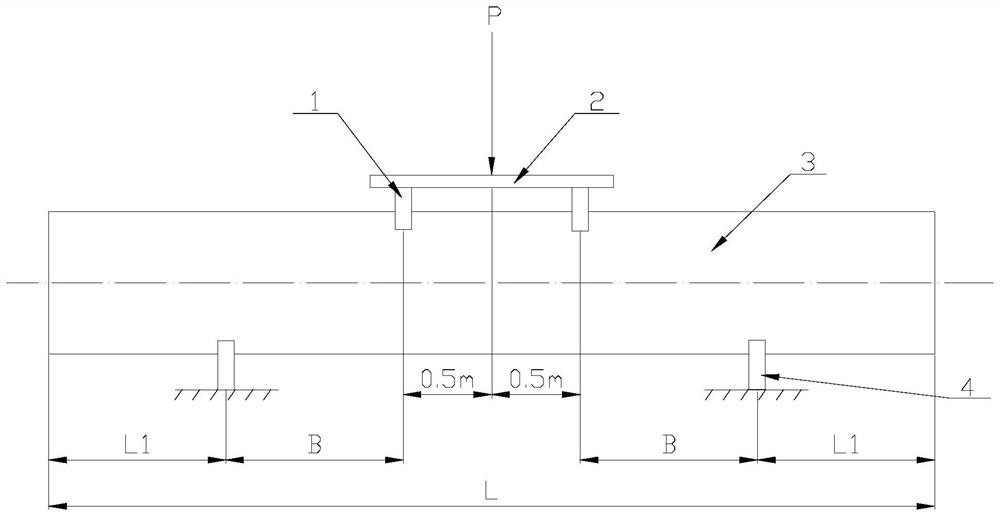

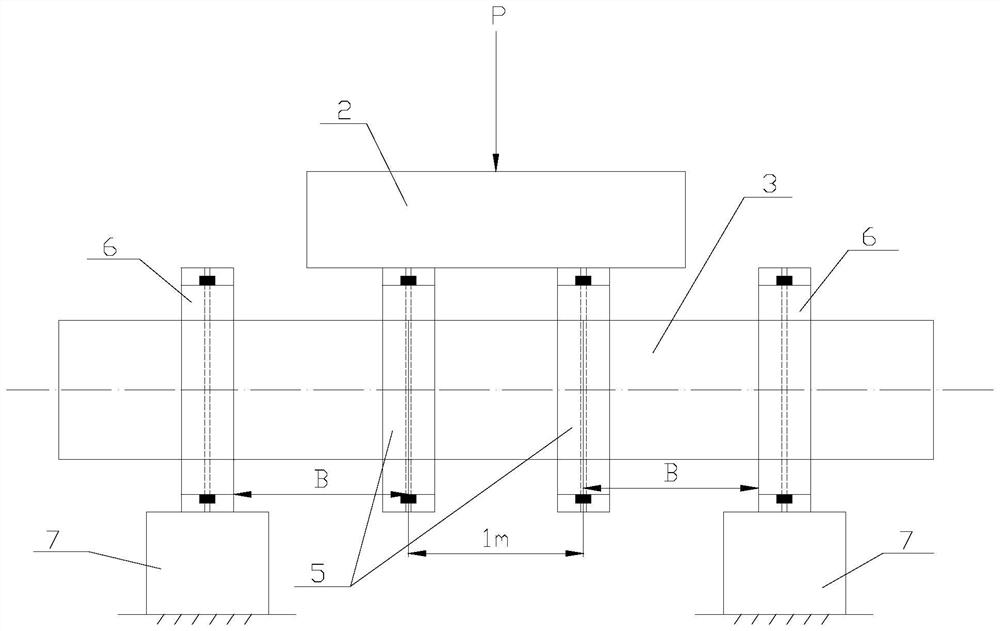

[0026] see Figure 2 to Figure 5 , the layout structure of the PHC pipe pile shear test of the present invention, including the test PHC pipe pile 3, two inner clamping supports 5, two outer clamping supports 6, distribution beam 2 and two piers 7; wherein, the PHC pipe pile 3 for the test is arranged horizontally; the two inner clamping supports 5 are symmetrically arranged at 0.5m on both sides of the length center of the PHC pipe pile 3 for the test, and the two outer clamping supports 6 are symmetrically arranged at 0.5m+shear span B on both sides of the length center of the test PHC pipe pile 3; the distribution beam 2 is arranged on the top surface of the two inner clamping supports 5; On the bottom surface of the two outer clamping supports 6 .

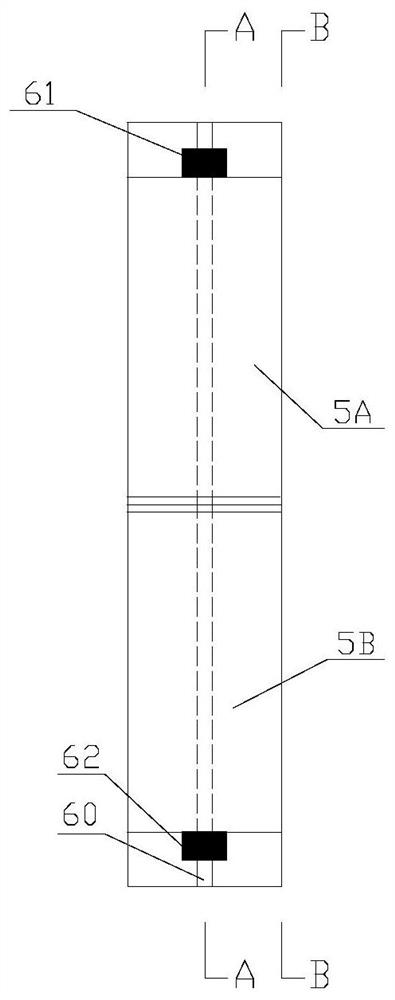

[0027] The inner clamping support 5 and the outer clamping support 6 have the same structure and include an upper half c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com