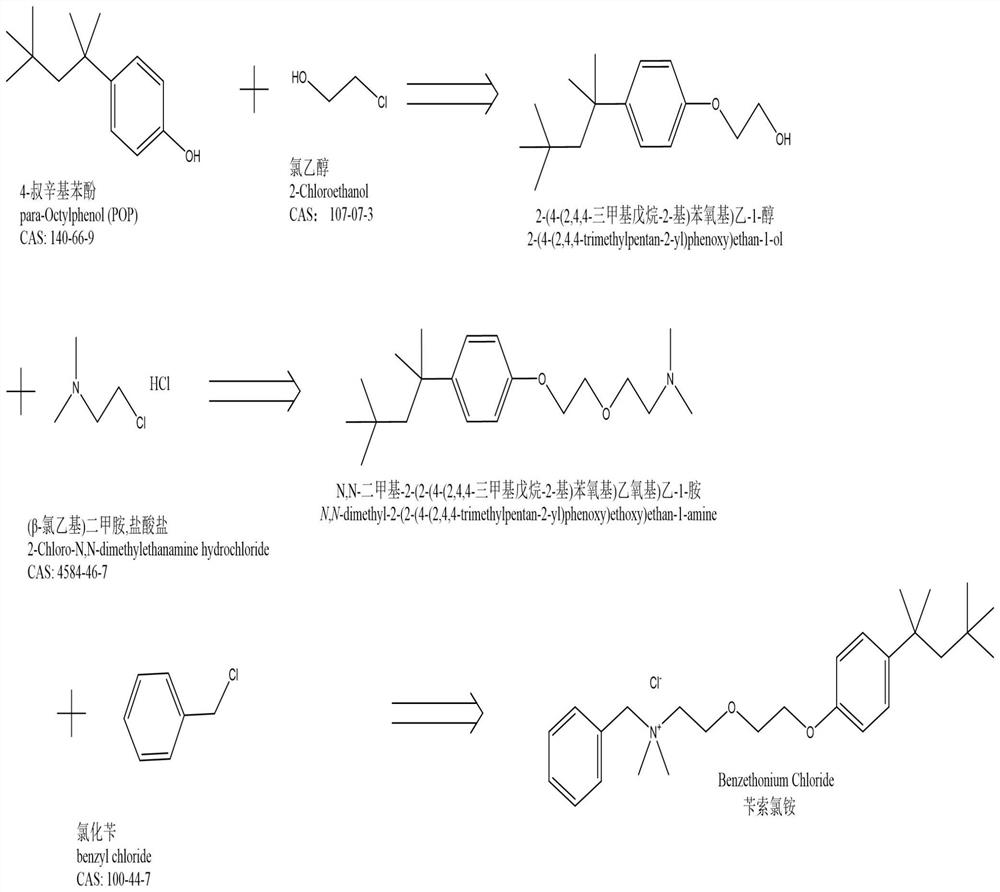

Production and preparation process of benzethonium chloride

A kind of benzethonium chloride, the technology of preparation process, is applied in the field of preparation of benzethonium chloride, can solve the problem such as high reaction temperature, achieve the effect of good purity, few by-products, low volatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0021] Weigh 210 grams of 4-tert-octylphenol and dissolve it in 85 grams of chloroethanol, stir and heat to about 65 ° C, and react for 4 hours, then slowly add 145 grams of (β-chloroethyl) dimethylamine, hydrochloride and 200 grams of 20% sodium hydroxide solution, after the dropwise addition is completed, slowly rise to 80 °C at a rate of 10 °C per hour, react under reflux for 6 hours, then cool and stand for stratification. Phase layer, wash the organic layer twice with ethyl acetate, and filter to obtain N,N-dimethyl-2-(2-(4-(2,4,4-trimethylpentan-2-yl)) Phenoxy)ethoxy)ethan-1-amine. It weighed 315.8 grams after drying.

[0022] Weigh 300 grams of the prepared N,N-dimethyl-2-(2-(4-(2,4,4-trimethylpentan-2-yl)phenoxy)ethoxy)ethane-1 - The amine was dissolved in 500ml of ethyl acetate solution, 100g of benzyl chloride was added dropwise at a rate of 2 drops per second, the temperature was raised to 80°C after the dropwise addition was completed, the reaction was stopped fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com