Granulated asphalt mixture additive as well as preparation method and application thereof

An asphalt mixture and additive technology, applied in the field of road engineering materials, can solve the problems of hardening, inconvenient use, unstable quality, etc., and achieve the effects of preventing hardening and improving dispersion performance and stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0054] The preparation method of the granulated asphalt mixture additive provided by the present invention comprises the following steps:

[0055] Heat the base asphalt binder to a fluid state, and mix it with the asphalt mixture modifier uniformly to form a mixed asphalt, so that the softening point of the mixed asphalt is between 90°C and 130°C;

[0056] The mixed asphalt is maintained at a temperature of 40°C to 70°C above the softening point temperature for granulation to obtain mixed asphalt additive particles; in a specific temperature range above the softening point, the fluidity of the mixed asphalt can be maintained at a stable level suitable for granulation. While maintaining the level after granulation, there is no need for additional temperature control, and the softness of the granule surface is suitable for coating the release agent.

[0057] After granulation, the mixed asphalt additive particles are quickly coated with antiblocking agent, and cooled to obtain t...

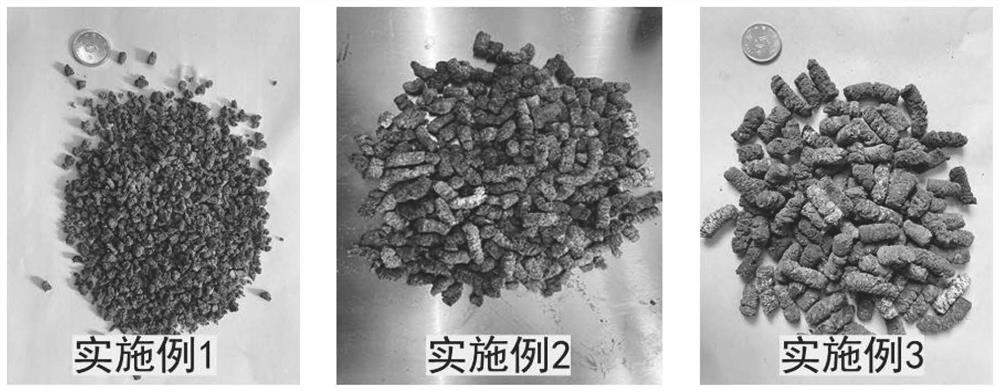

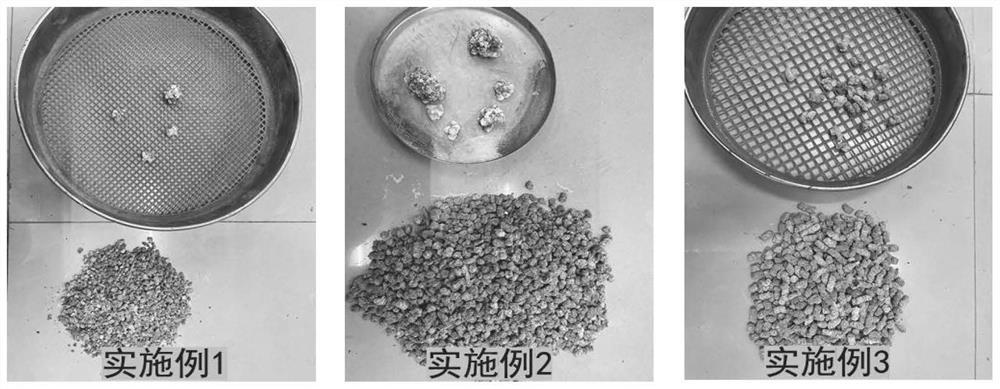

Embodiment 1 to 3

[0070] Embodiment 1 to 3 Heterogeneous phase asphalt mixture modifier and its preparation

[0071] The heterogeneous granulated asphalt mixture additive provided in this example includes asphalt modifier, base asphalt, and anti-blocking agent. The composition table is shown in the following table:

[0072]

[0073] The granulated asphalt mixture additives provided in the examples include asphalt modifiers and matrix asphalt, and the composition ratio table is shown in the following table:

[0074]

[0075]

[0076] The parameters of the release layer: Assuming that each particle is uniformly coated, the thickness of the release layer is obtained by dividing the mass of the release agent by the density of the release agent to obtain the volume of the release agent added, and then dividing the volume of the release agent by The N particle surface area yields the release agent thickness.

[0077]

[0078]

[0079] S k =2×πr 2 +2πr×L k

[0080] Where h is the t...

Embodiment 4 to 6

[0097] Embodiment 4 to 6 homogeneous phase asphalt mixture modifier and its preparation

[0098] The granulated asphalt mixture additive provided in this example includes asphalt modifier, base asphalt, and anti-blocking agent, and the composition table is shown in the following table:

[0099]

[0100]

[0101] The rubber powder used in this example is waste tire rubber powder with an average particle size of about 0.6 mm (passing through a 30-mesh sieve).

[0102] The granulated asphalt mixture additives provided in the examples include asphalt modifiers and matrix asphalt, and the composition table is shown in the following table:

[0103] Example Asphalt modifier base asphalt anti-sticking agent 4 50 50 0.2 5 60 40 0.2 6 70 30 0.2

[0104] The thickness of the release layer: Assuming that each particle is uniformly coated, the thickness of the release layer is obtained by dividing the mass of the release agent by the density ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com