Saline water purification device and heavy metal removal method

A purification device and heavy metal technology, applied in chemical instruments and methods, alkali metal chlorides, water pollutants, etc., can solve problems such as excessive dosage of chemicals, increased energy consumption of salt water evaporation, and low purity of salt products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

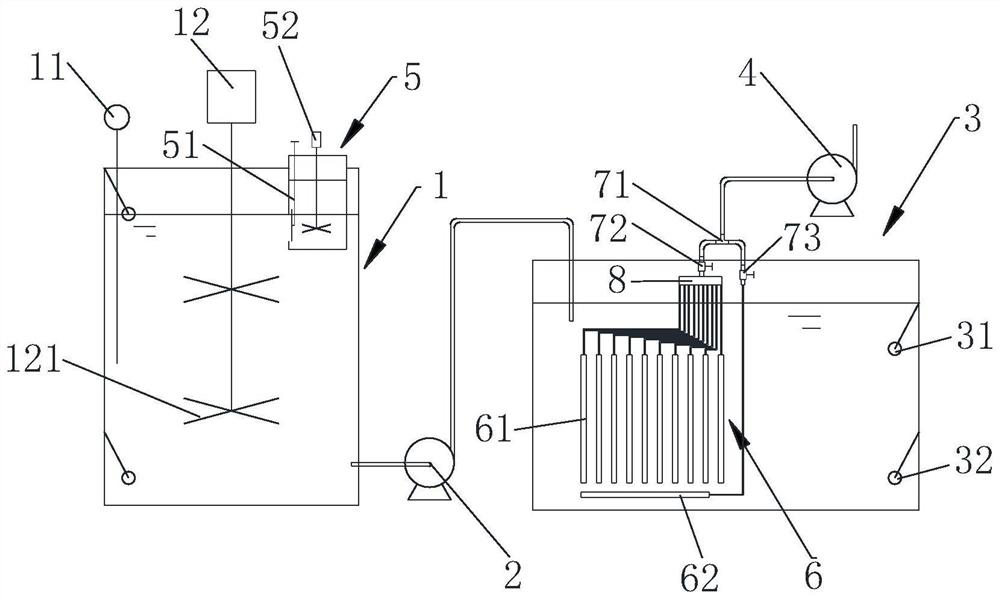

[0053] Example 1: Brine purification device

[0054] see figure 1 As shown in the figure, the structure of the salt water purification device of the present invention includes: a mixing barrel 1, a water pump 2, a filter barrel 3, and a self-priming pump 4 connected in sequence by pipelines; the upper opening of the mixing barrel 1 is equipped with a mixer 5 and a The electric mixer 12, the filter barrel 3 is provided with a flat membrane assembly 6; the three-way pipe 71 connects the self-priming pump 4 with the first electric ball valve 72 and the second electric ball valve 73, and the first electric ball valve 72 is connected with ten heads The flow divider 8 is connected to the water production port of the first flat membrane placed vertically through the pipeline, and the second electric ball valve 73 is connected to the water production port of the second flat membrane placed horizontally through the pipe joint and the pipeline.

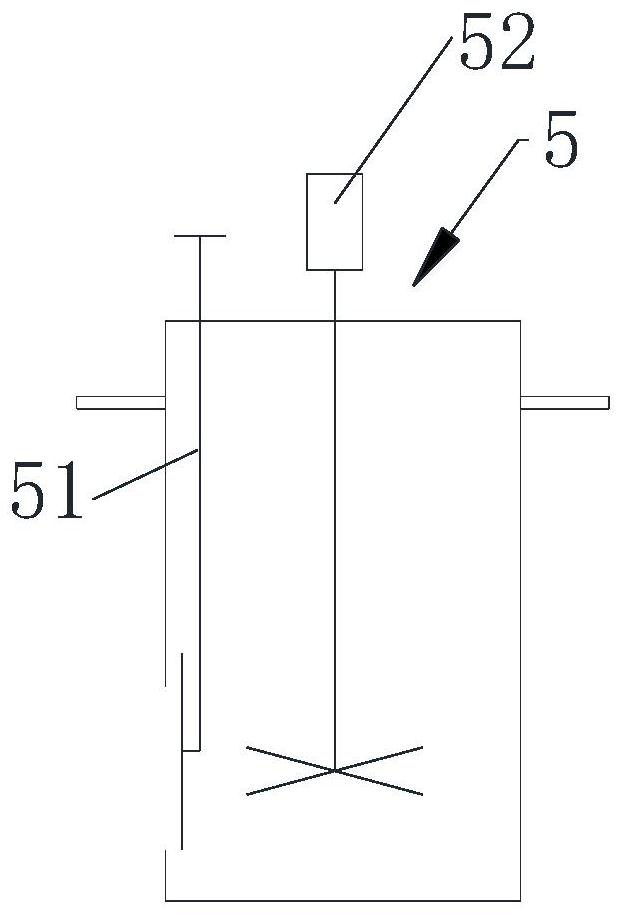

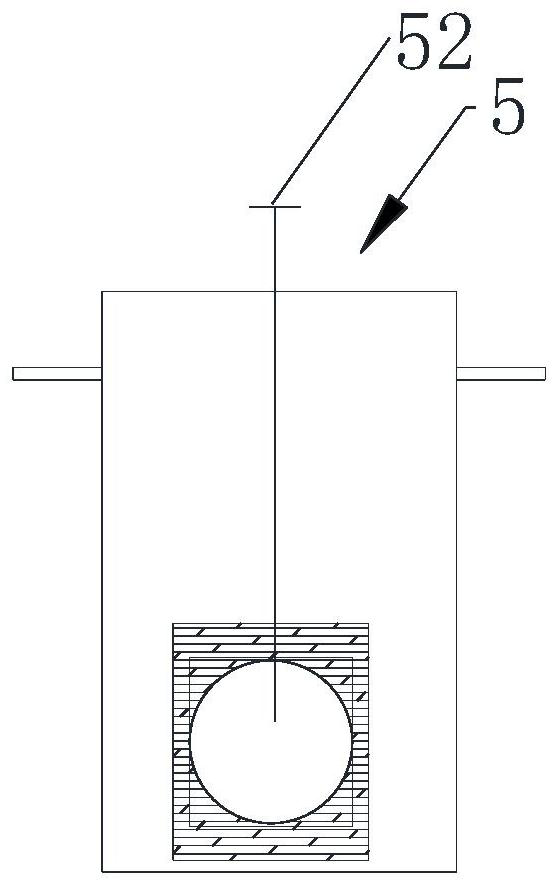

[0055] see figure 2 , image 3 As sh...

Embodiment 2

[0059] Example 2: Flat membrane filtration and cleaning of salt water purification device

[0060] The salt water containing heavy metal sediments that has been mixed and precipitated in the 1-ton mixing tank 1 is transported to the filter tank 3 by the water pump 2. The flat membrane module 6 in the filter tank 3 is composed of 10 vertically parallel flat membranes 61 and 1 horizontally placed The horizontal flat film 61 is placed under 10 vertical flat films 62. The distance between the top of the vertical flat membrane 61 and the upper part of the filter barrel 3 is 300 mm. The first float level gauge 72 controls the start and stop of the water pump 2 . When the liquid level and the upper part of the filter bucket 3 are less than 100mm, the water pump 2 stops working, and the salt water in the mixing bucket 1 will not enter the filter bucket 3 again. When the liquid level and the upper part of the filter bucket 3 are greater than 300mm, the water pump 2 is started, and th...

Embodiment 3

[0063] Example 3: Sodium chloride brine purification and acid adjustment

[0064] Adjust the pH value of the brine before removing heavy metals by using the brine purification device in Example 1, and adjust the pH of the brine from 11 to 6.5 by using concentrated hydrochloric acid. According to the beaker experiment, add 2.5ml of concentrated hydrochloric acid per liter of brine, when the mixer gate valve 51 It has been closed, the mixer 5 contains brine, and when the mixer 52 on the upper part of the mixer 5 is in a stirring state, it starts to add concentrated hydrochloric acid. According to the proportional enlargement of the beaker test, it is necessary to put 2.5L of concentrated hydrochloric acid into the stirring tank 1 of 1 ton of brine, and use a syringe (not shown in the figure) to inhale 1L of concentrated hydrochloric acid and inject it into the liquid injection port above the mixer 5 (not shown in the figure), After the injection is completed, wait for 1 minute, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com