Energy-saving concrete pouring and curing device and method

A concrete and energy-saving technology, applied in the field of concrete, can solve the problems of limited movement range of sponge pads, poor maintenance effect of concrete pouring, etc., and achieve the effect of maintaining water absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0047] A curing method for a concrete cast body, using the curing device in Example 1, comprises the following steps;

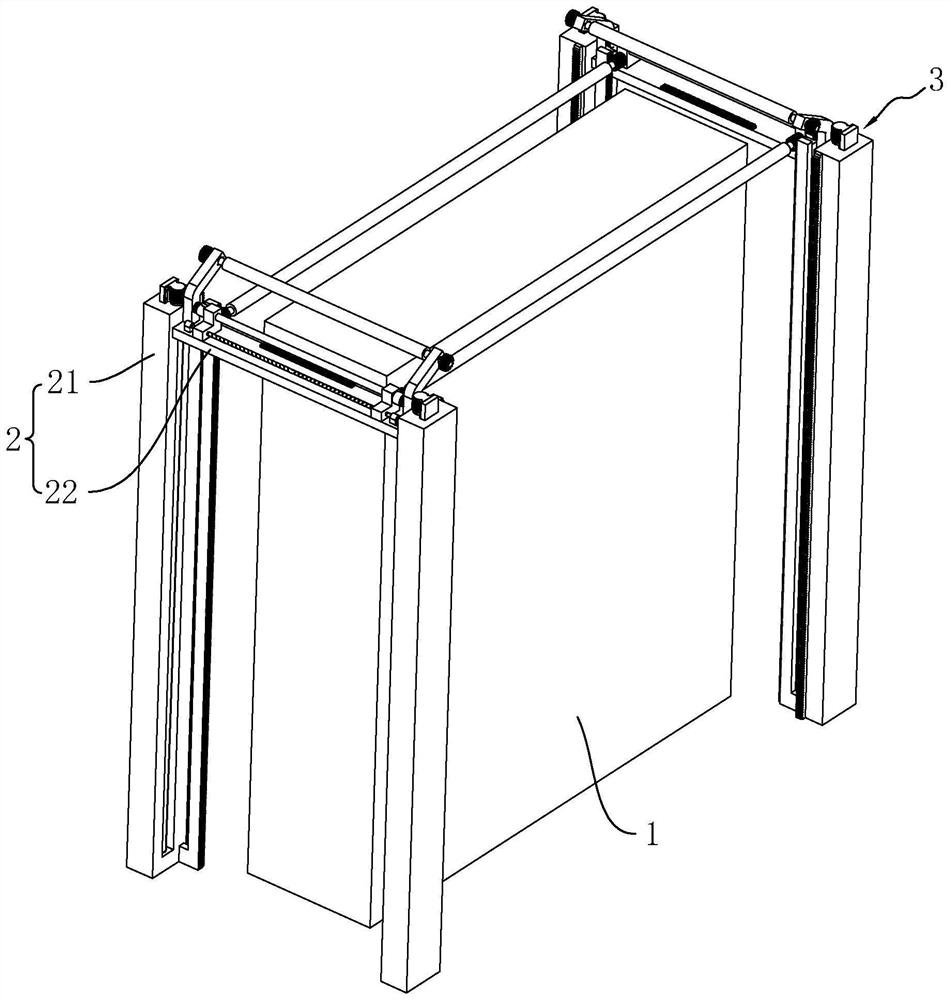

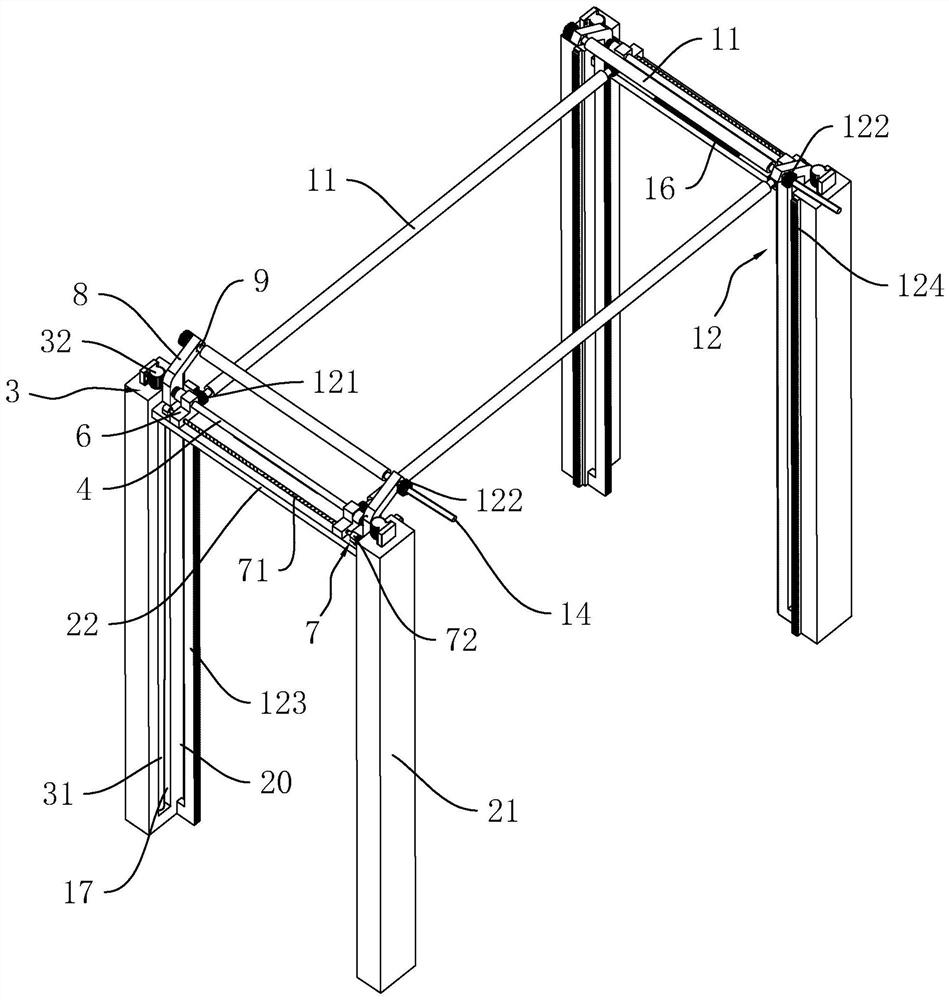

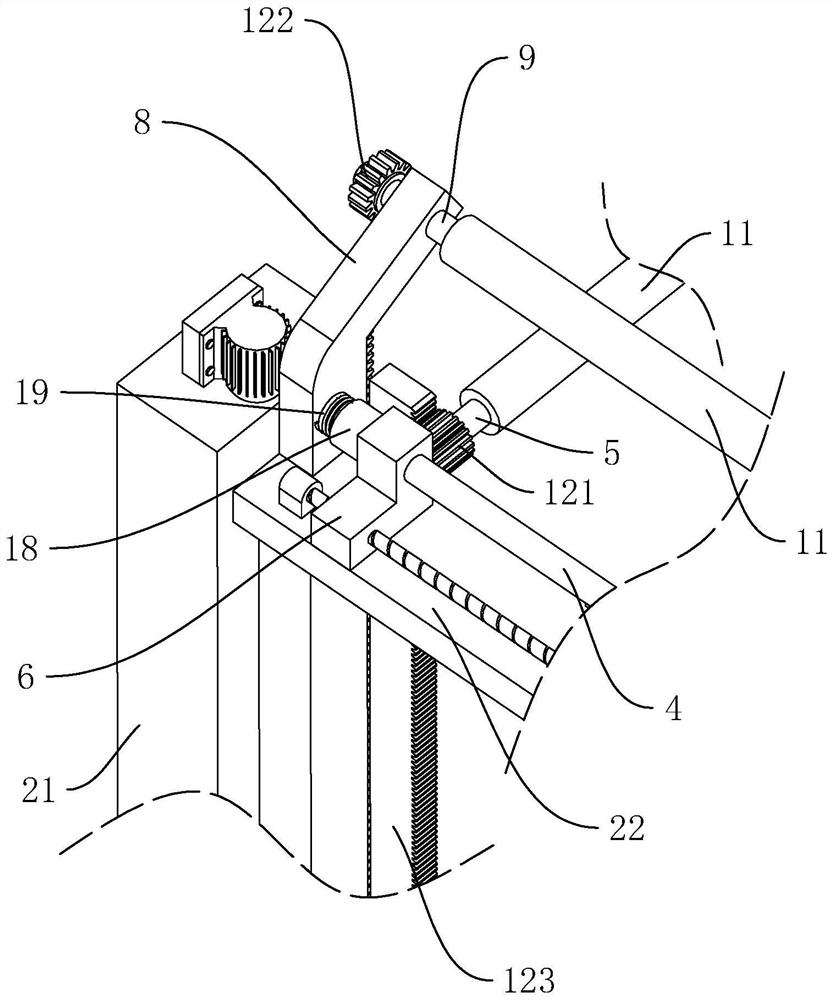

[0048] S1. The concrete cast body to be cured is placed between the two groups of support frames 2, and when the first rotating roller 5 and the second rotating roller 9 move up and down, the sponge layer 11 can abut the side wall of the concrete cast body ;

[0049] S2. After the concrete casting body is placed, drive the mounting plate 22 to move up and down through the driving member 3, the first gear 121 meshes with the first rack 123, the second gear 122 can mesh with the second rack 124, and the side wall of the concrete casting body After curing, the mounting plate 22 is driven to move to the upper end of the concrete casting body by the driving member 3, and the sliding bases 6 are driven to approach each other by the power member 7, at this time, the first gear 121 can mesh with the third gear.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com