Universal inclined plane milling tool equipment for excavator

A technology for tooling equipment and inclined milling, which is applied in metal processing equipment, manufacturing tools, metal processing, etc., can solve problems such as falling into threaded holes, poor practicability, and inconvenient sealing of threaded holes, so as to facilitate turning and milling and improve practicability , the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

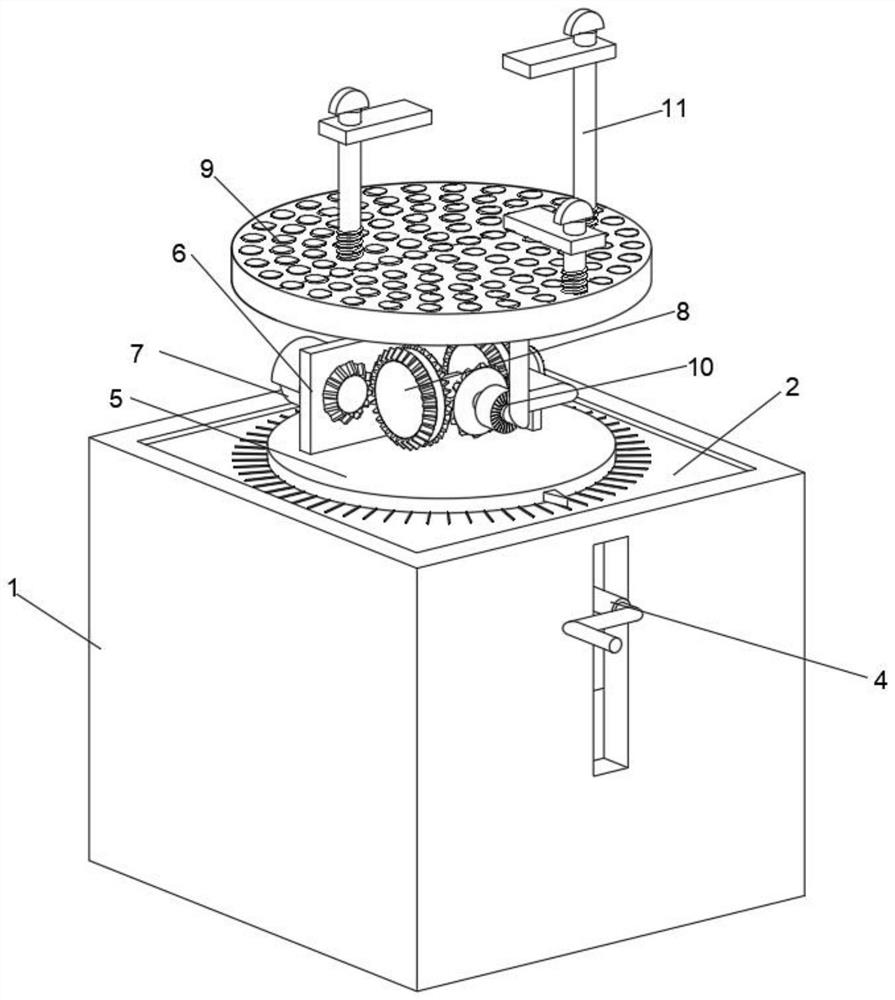

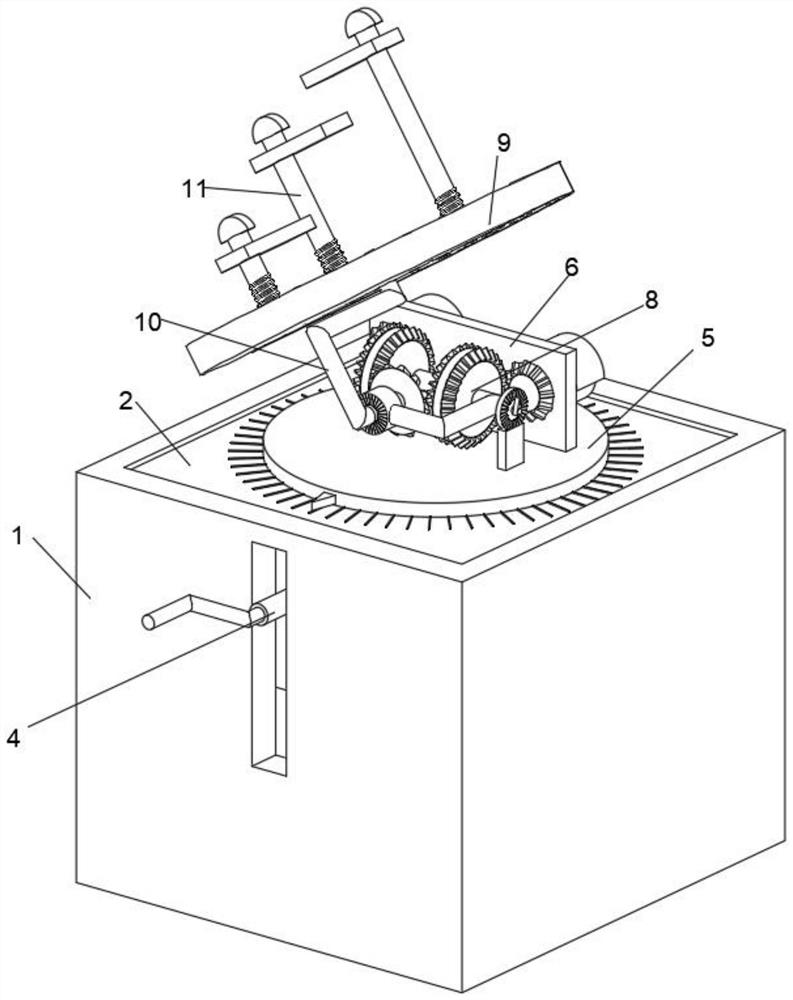

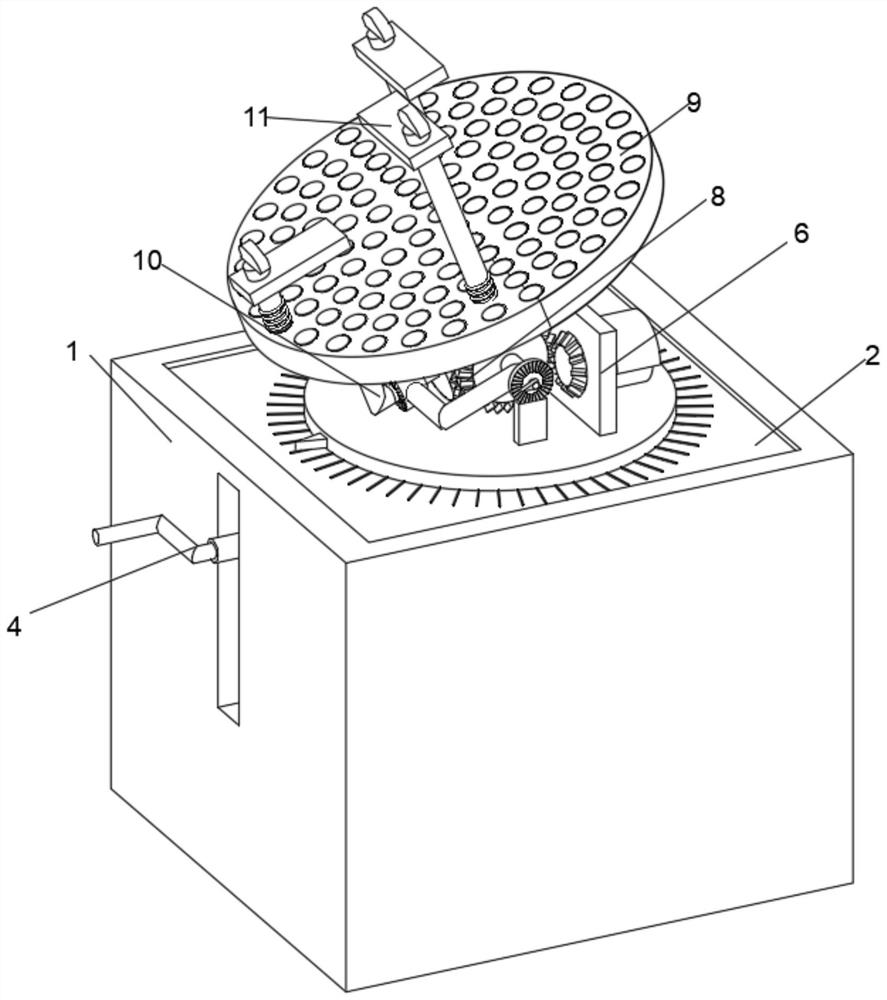

[0028] Please refer to Figures 1-6, the present invention provides a technical solution:

[0029] A universal milling inclined surface tooling equipment for excavators, comprising an equipment base 1, an equipment table 2 is arranged inside the upper side of the equipment base 1, a placement groove 3 is opened inside the equipment table 2, an adjustment component 4 is arranged in the placement groove 3, and the equipment table 2 The top surface is provided with an adjustment seat 5, the top surface of the adjustment seat 5 is provided with a fixed plate 6, the rear side of the fixed plate 6 is connected and fixed with two motors 7 in a symmetrical structure, the front side of the fixed plate 6 is provided with a transmission assembly 8, and the adjustment seat 5 A fixing seat 9 is arranged on the upper side, a transmission rod 10 is arranged on the lower side of the fixing seat 9 , and a plurality of clamping assemblies 11 are arranged on the top surface of the fixing seat 9 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com