Seamless integrated weaving method for down jacket fabric

A down jacket fabric, seamless technology, applied in the field of fabric weaving, can solve the problems of residual down at the filling mouth, easy to open glue, and wrinkles on the edge of the fabric, etc., and achieve the effect of improving the washing resistance and anti-drilling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

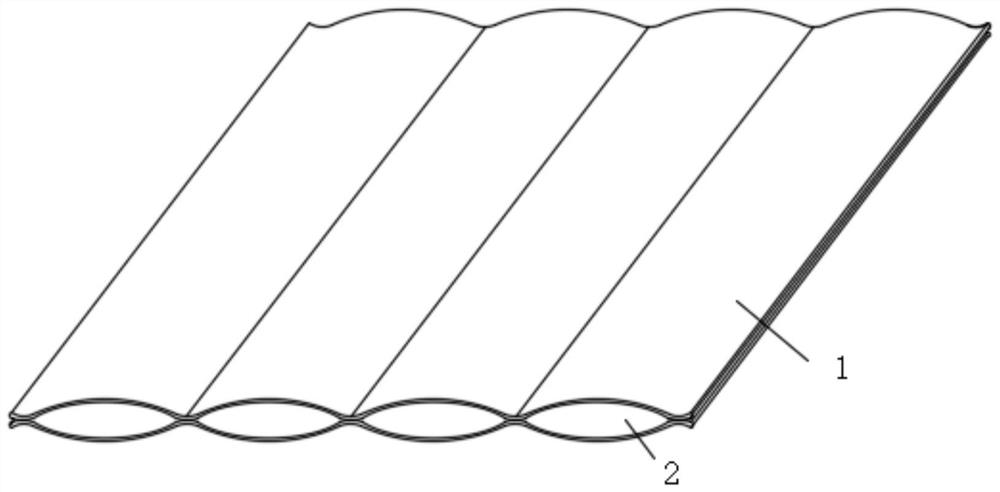

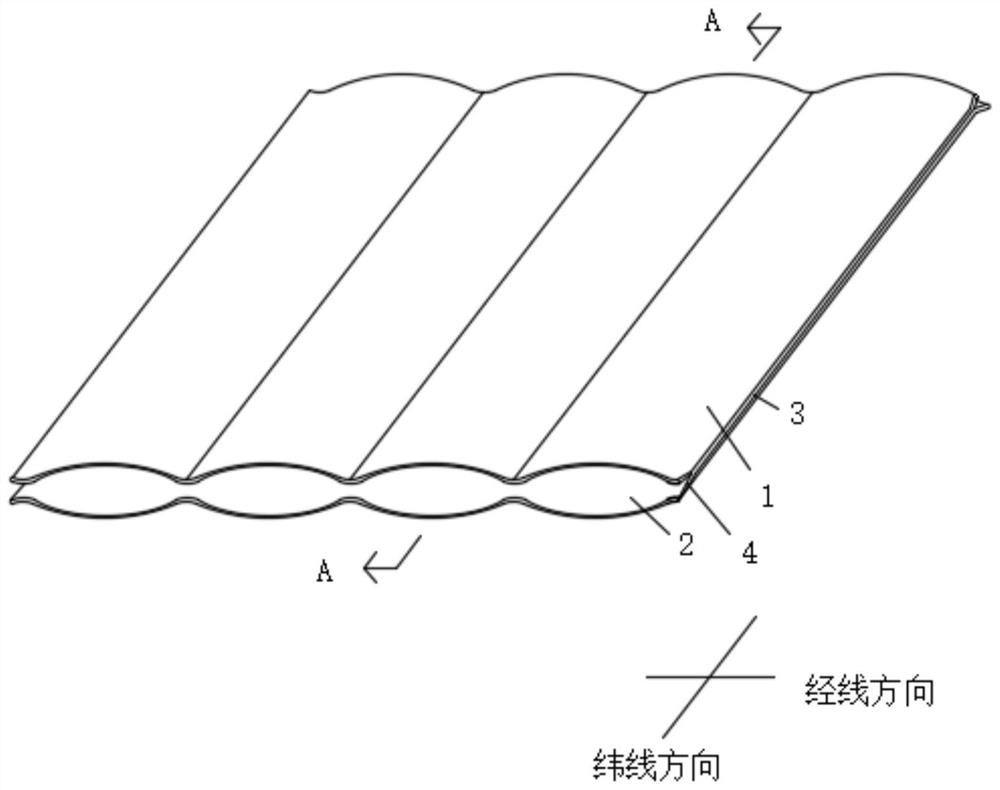

[0025] like Figure 2-4 As shown, a seamless integrated weaving method of down jacket fabric includes the following steps:

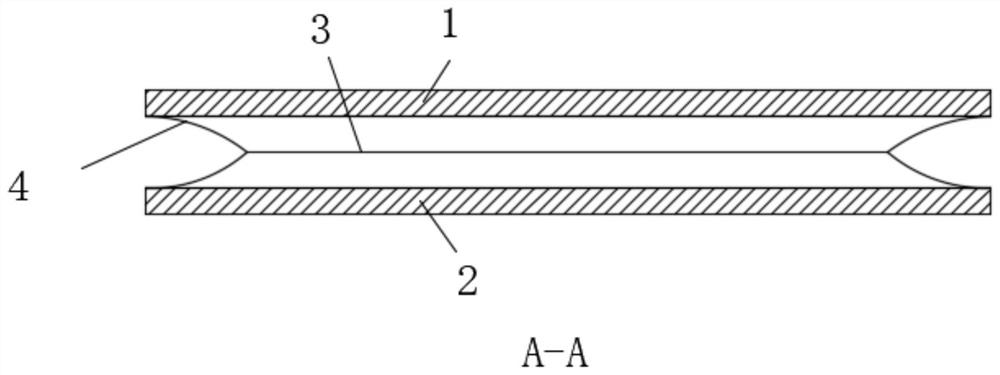

[0026] S1: The surface fabric 1 and the inner fabric 2 are woven in parallel and synchronously by weaving. During the weaving process, the wefts of the surface fabric 1 and the inner fabric 2 bypass each other's warp threads, so that the surface fabric 1 and the inner fabric 2 are cross-connected to each other to form a joint part 3, wherein the length of the joint part 3 is shorter than the width of the surface layer fabric 1 and the lining 2, so that the two sides of the surface fabric 1 and the lining 2 form a gap 4;

[0027] S2: Sew the filling strip 5 to make the filling strip 5 in the shape of a long strip and fit the shape of the gap 4, and use the thermocompression bonding technology to bond the filling strip 5 to the gap 4 on one side through the adhesive 6;

[0028] S3: Fill the compartment between the surface fabric 1 and the lining 2 from th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com