Benomyl wettable powder and preparation method thereof

A technology of wettable powder and benomyl, which is applied in the field of pesticides, can solve the problems of bag swelling and agglomeration, and achieve the effect of solving bag swelling, good fluidity, and reducing the risk of pesticide damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

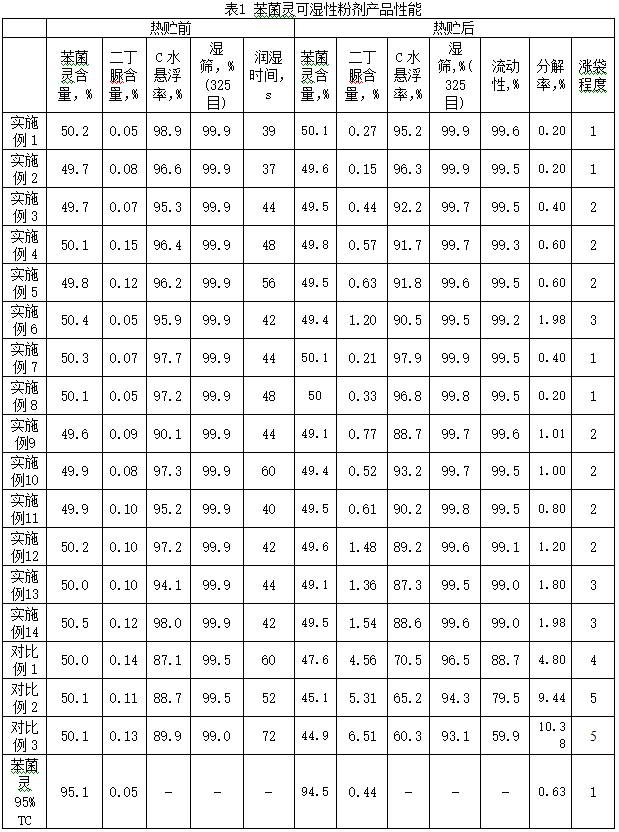

Examples

Embodiment 1

[0035] A benomyl wettable powder, its formula is (wt%): benomyl 50.0%, dispersant calcium lignosulfonate 3.75%, polycarboxylate sodium salt 1.25%, wetting agent sodium lauryl sulfate 1.5%, filler sucrose 25.0%, ordinary silica 2.5%, fumed silica 0.5%, anhydrous sodium sulfate supplement 100%.

[0036] The preparation method is as follows: the original drug of benomyl is pulverized to a particle size of 15-30 μm by an air-jet pulverizer; the dispersant, wetting agent and various fillers are mixed uniformly, and then pulverized to a particle size of 15-30 μm by an air-jet pulverizer; The pulverized auxiliary agent is mixed with the pulverized original drug for a second time, and the benomyl wettable powder is obtained after mixing evenly.

Embodiment 2

[0038] A benomyl wettable powder, the formula of which is (wt%): benomyl 50.0%, dispersant calcium lignosulfonate 4.5%, sodium polycarboxylate 1.5%, wetting agent sodium lauryl sulfate 2.0%, filler sucrose 25.0%, ordinary silica 2.5%, fumed silica 0.5%, and modified corn starch supplement 100%.

[0039] The preparation method is the same as in Example 1.

Embodiment 3

[0041] A benomyl wettable powder, the formula of which is (wt%): benomyl 50.0%, dispersant calcium lignosulfonate 5.0%, wetting agent sodium lauryl sulfate 1.5%, filler sucrose 25.0%, Ordinary silica 2.5%, fumed silica 0.5%, and anhydrous sodium sulfate make up 100%.

[0042] The preparation method is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com