Superlattice phase change structure, manufacturing method thereof and phase change memory

A phase-change storage and superlattice technology, applied in semiconductor devices, electric solid-state devices, electrical components, etc., can solve the problems of large RESET current, less cycle times, and low SET speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

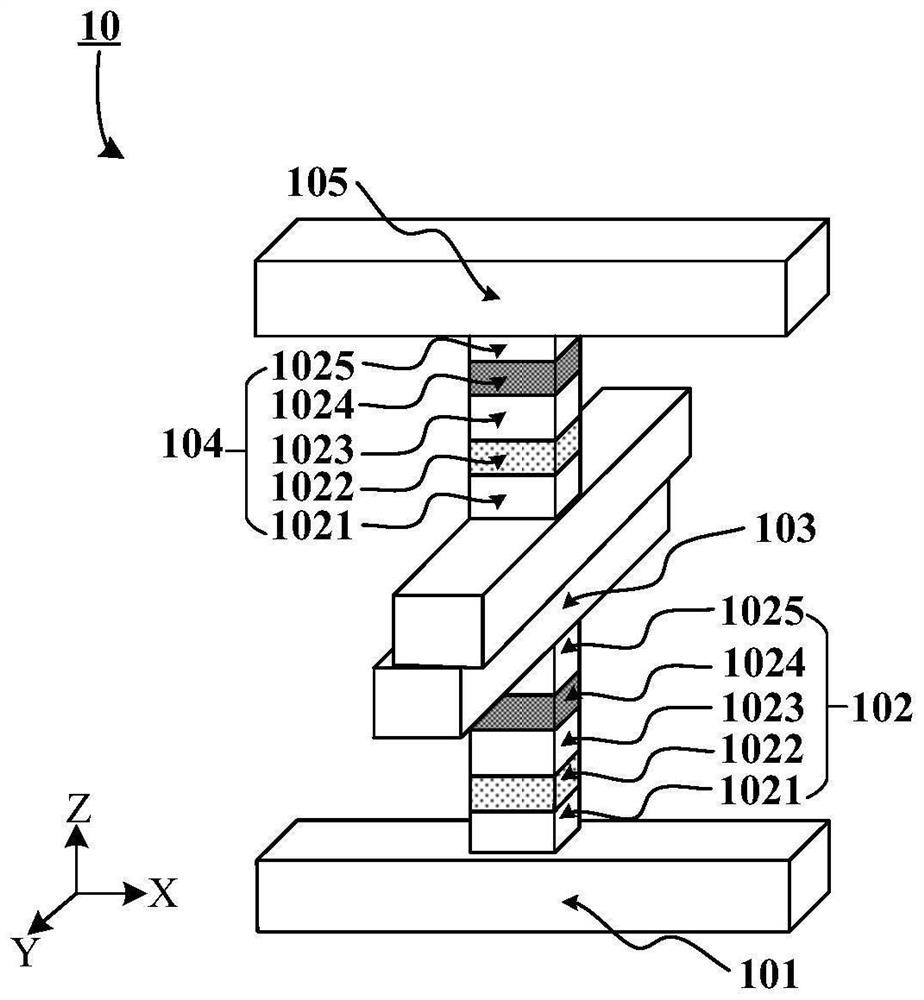

[0030] The technical solutions of the present application will be further elaborated below with reference to the accompanying drawings and embodiments. While exemplary implementations of the present application are shown in the drawings, it should be understood that the present application may be implemented in various forms and should not be limited by the embodiments set forth herein. Rather, these embodiments are provided so that a more thorough understanding of the present application will be provided, and will fully convey the scope of the present application to those skilled in the art.

[0031] Embodiments of the present application are described in more detail by way of example in the following paragraphs with reference to the accompanying drawings. Advantages and features of the present application will become apparent from the following description and claims. It should be noted that, the accompanying drawings are all in a very simplified form and use inaccurate sca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com