Strip steel cold rolling pickling parameter optimization method

An optimization method and pickling technology, which is applied in the field of cold rolling, can solve the problems that the pickling parameters cannot achieve the best strip pickling effect, and achieve the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

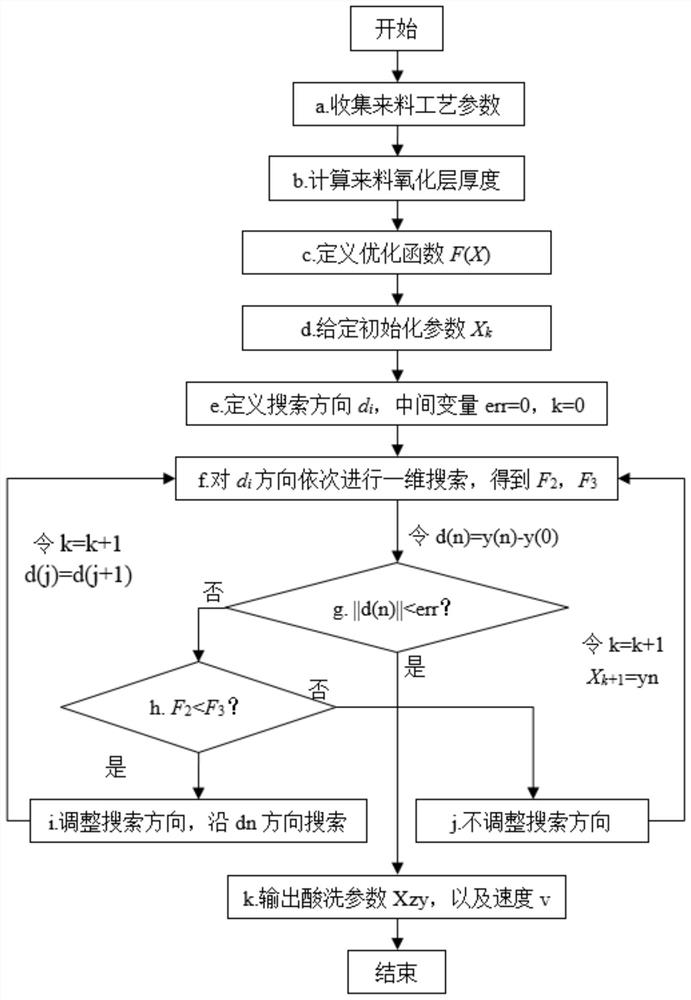

[0028] like figure 1 As shown, the embodiment of the present invention provides a method for optimizing the pickling parameters of strip cold rolling, including the following steps executed by a computer:

[0029] (a) Collect incoming process parameters;

[0030] (b) Calculate the thickness h of the incoming oxide layer: because there is a functional relationship between the thickness of the incoming iron oxide scale and the incoming process parameters, h=f(P, C, Si, Mn, T j ), where P is the strip steel grade, T j is the coiling temperature; the incoming iron oxide scale is calculated according to the collected incoming process parameters;

[0031] (c) Define the optimization function F(X)=f(h,X);

[0032] (d) Given initialization parameter X;

[0033] (e) define the search direction;

[0034] (f) Perform a one-dimensional search in the search direction: let y0=X(k), perform a one-dimensional search along d0, d1, d2, d3 in turn, for all j=1, 2, 3, 4, denote f(y (j-1)+λ(...

Embodiment 2

[0045] like figure 1 As shown, the embodiment of the present invention provides a method for optimizing the pickling parameters of strip cold rolling, including the following steps executed by a computer:

[0046] (a) Collection of incoming process parameters: randomly collect a group of incoming process parameters of a certain grade of strip steel, mainly including incoming grade A510L, C content of 0.155%, Si content of 0.9%, Mn content of 1.85% and coiling temperature of 500°C;

[0047] Subsequently, in step (b), the thickness h of the incoming oxide layer is calculated: because there is a functional relationship between the thickness of the incoming iron oxide scale and the incoming process parameters, h=f(P,C,Si,Mn,T j ), where P is the strip steel grade, T j is the coiling temperature. According to the collected incoming process parameters, the incoming iron oxide scale is calculated, and the calculated result is 22 μm;

[0048] Then, in step (c), define an optimizati...

Embodiment 3

[0057] like figure 1 As shown, the embodiment of the present invention provides a method for optimizing the pickling parameters of strip cold rolling, including the following steps executed by a computer:

[0058] (a) Collection of incoming process parameters: randomly collect a group of incoming process parameters of a certain grade of strip steel, mainly including incoming grade JSH440W, C content 0.17%, Si content 1.35%, Mn content 2.1% and coiling temperature 500 ℃;

[0059] Subsequently, in step (b), the thickness h of the incoming oxide layer is calculated. Since there is a functional relationship between the thickness of the incoming iron oxide scale and the incoming process parameters, h=f(P,C,Si,Mn,T j ), where P is the strip steel grade, T j is the coiling temperature. According to the collected process parameters, the incoming iron oxide scale is calculated, and the calculated result is 24 μm;

[0060] Then, in step (c), define an optimization function F(X)=f(h,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com