Mixed valve type magnetorheological damper

A magneto-rheological damper, hybrid technology, applied in the direction of shock absorber, shock absorber, spring/shock absorber, etc., can solve the problems of magnetorheological damper power supply limitation, etc., and achieve the improvement of adjustable damping range, The effect of expanding the safe working range and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

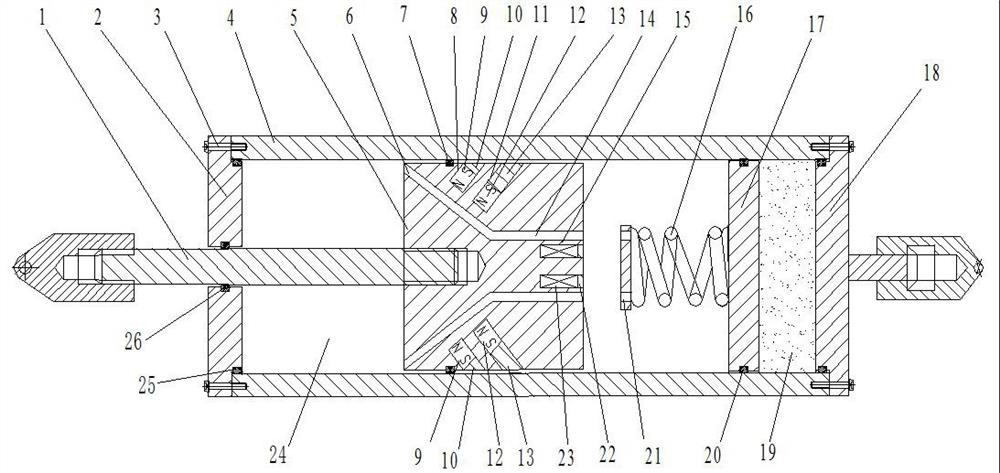

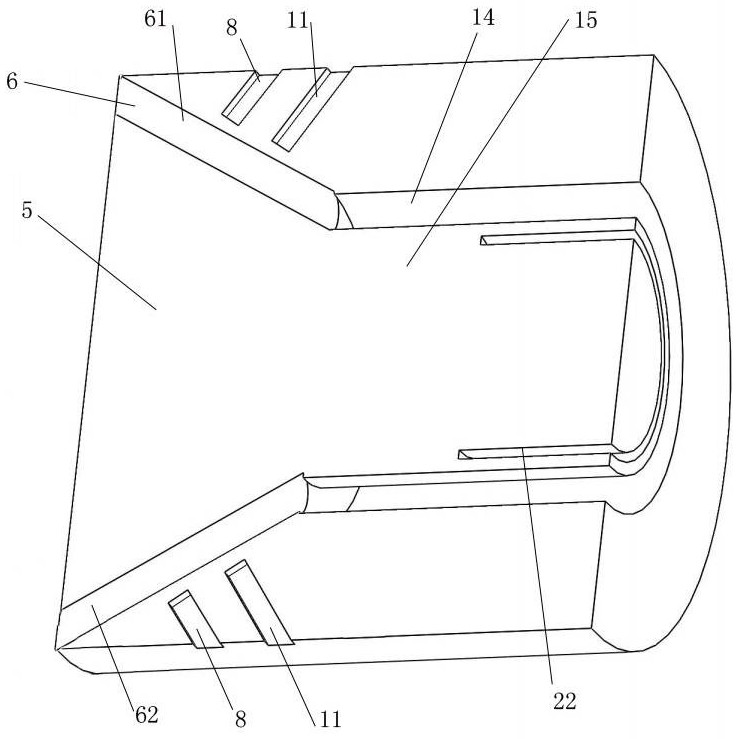

[0031] like Figure 1-2 As shown, the hybrid valve-type magnetorheological damper includes a piston rod 1, a left end cover 2, a cylinder block 4, a piston head 5, and a coil 23;

[0032] The magnetorheological fluid 24 is injected into the inner space of the cylinder block 4; the right end of the piston rod 1 enters the cylinder block 4 through the piston hole in the middle of the left end cover 2, and can slide relative to the piston rod hole; the The right end of the piston rod 1 is fixedly connected to the middle of the top surface of the left end of the piston head 5;

[0033] The right end surface of the piston head 5 is provided with a ring groove 14, the inner top surface of the ring groove 14 is provided with a cylindrical body 15, and the right end surface of the cylindrical body 15 is provided with a coil ring groove 22. The coil 23 is arranged in the coil ring groove 22, and is sealed by the magnetic conductive material;

[0034] The left end of the piston head 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com