Train loading 3D model front-end assembly and display method

A display method and model technology, which is applied in the field of train loading, can solve the problems of inconvenient inspection and untrue and complete loading, and achieve the effect of convenient inspection and review of loading conditions and visual assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

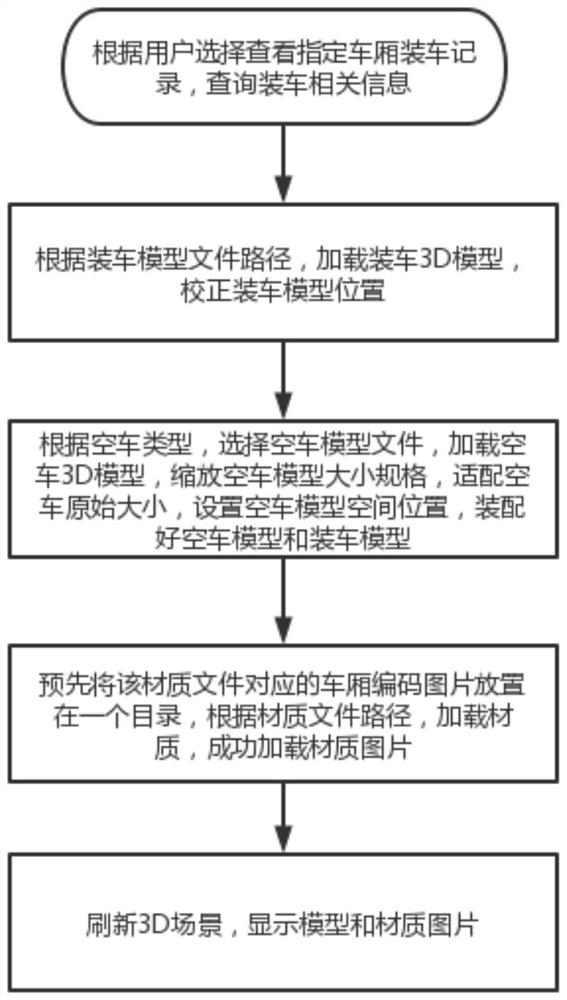

[0027] see figure 1 , the front-end assembly and display method of the train loading 3D model provided by this embodiment includes the following steps:

[0028] 1) Load the pre-generated loading 3D model, correct the position of the loading 3D model, and adjust the center of gravity of the loading 3D model to the origin;

[0029] 2) Obtain the empty car model according to the prefabricated model file, adjust the size and specification of the empty car model, and match it with the loading 3D model of step 1);

[0030] 3) Assemble the loaded 3D model and the empty model to obtain the overall model;

[0031] 4) Map the overall model in step 3) to obtain the final visualized model.

[0032] In the present embodiment, the concrete process of step 1) is:

[0033] 1.1) According to the file path of the loading model, use the PLYLoader module of the three.js engine to pre-load the generated loading 3D model, and determine the X-axis, Y-axis and Z-axis of the loading 3D model;

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com