System and method for detecting internal cracks of prebaked anode carbon block

A technology for detecting system and internal cracks, which is applied in the direction of measuring devices, processing detection response signals, instruments, etc., can solve the problems of increased free vibration damping, more labor occupation, and a large number of inspection personnel, so as to improve accuracy and high operating efficiency , the effect of reducing interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0091] In order to make those skilled in the art better understand the technical solutions of the present invention, the present invention will be further described in detail below with reference to the accompanying drawings.

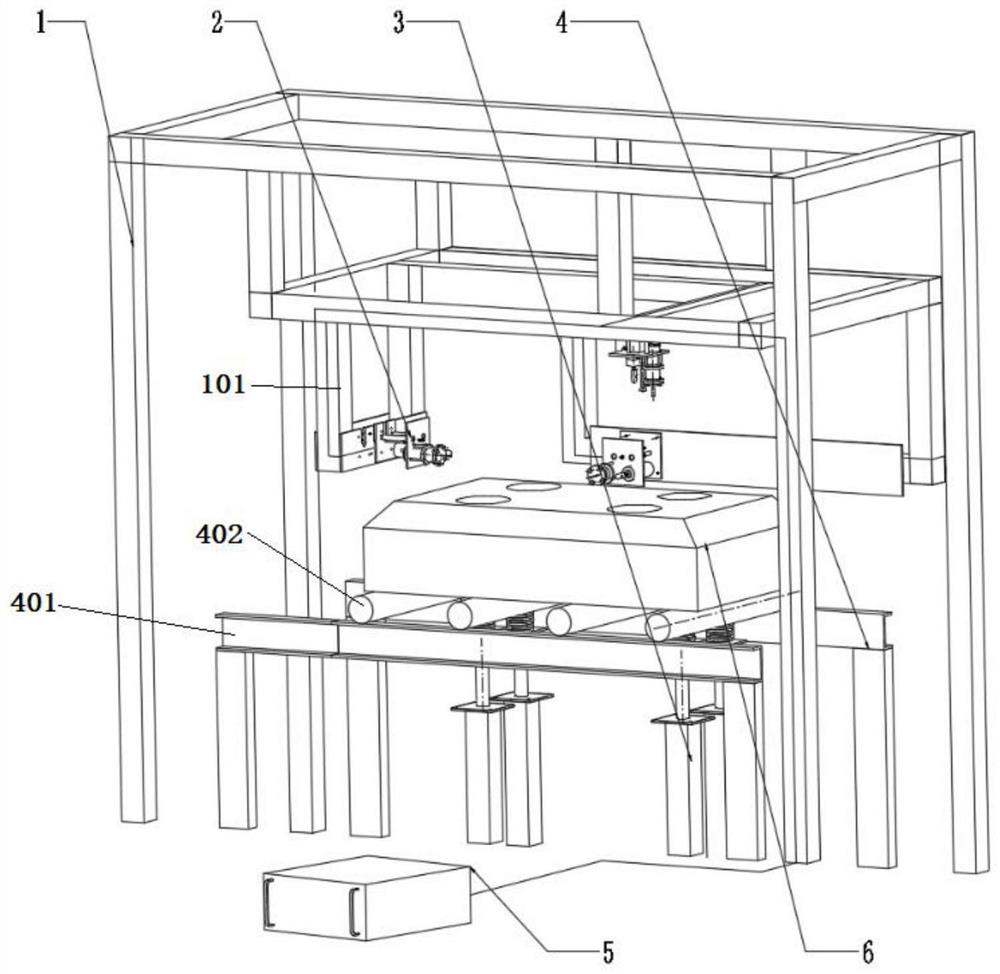

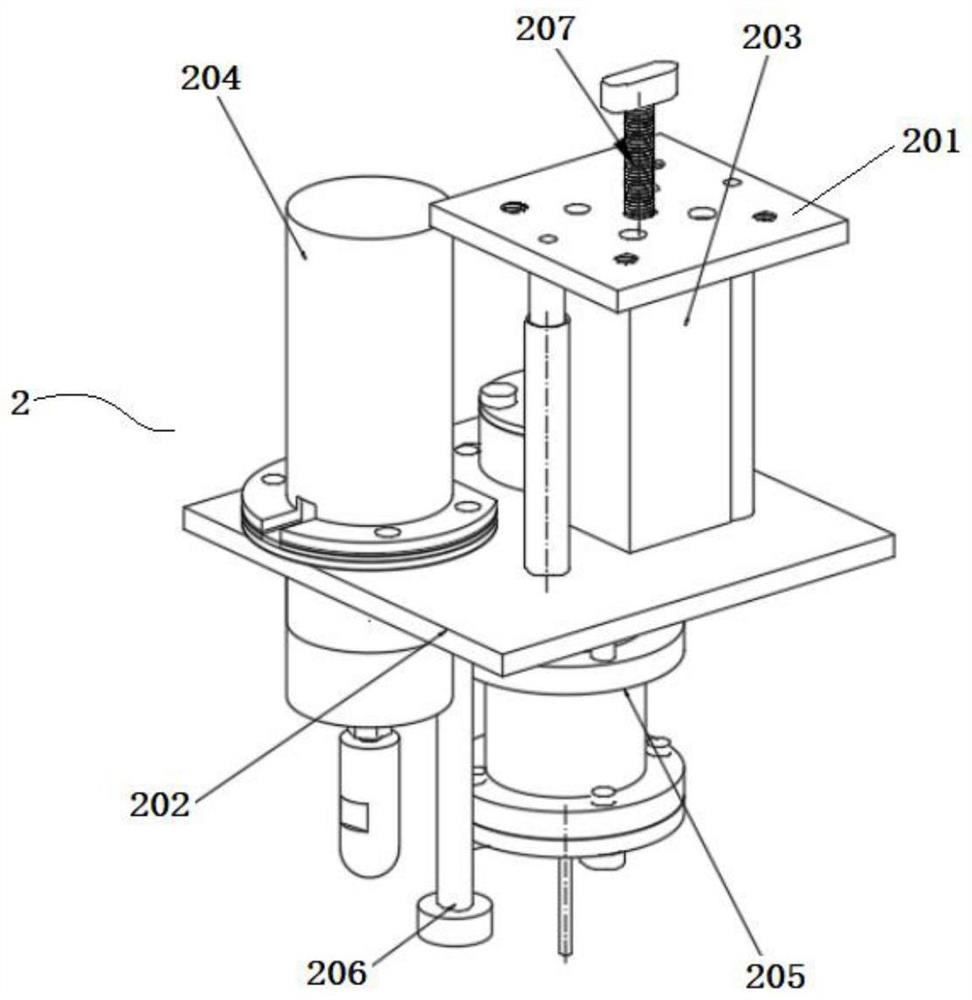

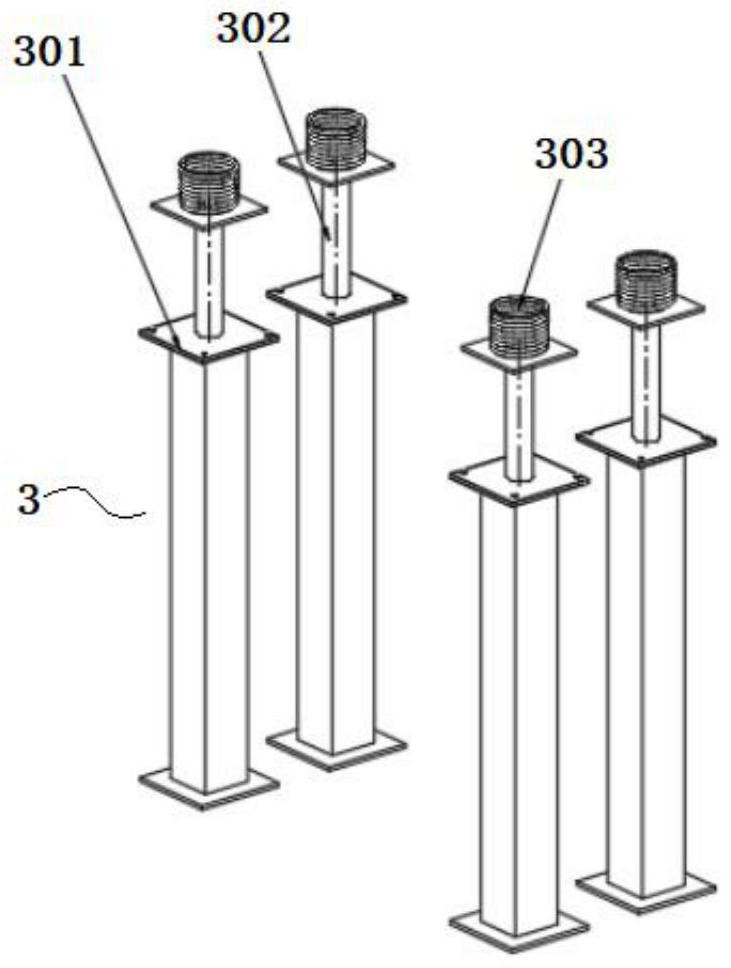

[0092] see Figure 1 to Figure 5 shown;

[0093] A system for detecting internal cracks in a prebaked anode carbon block of the present embodiment, the detection system includes:

[0094] support frame 1;

[0095] a conveying mechanism 4 for conveying the carbon blocks 6; and

[0096] The knocking mechanism 2 capable of knocking the carbon block 6;

[0097] There is a jacking mechanism 3 below the support frame 1, and the jacking mechanism 3 can support the carbon block 6 and drive the carbon block away from the conveying mechanism 4;

[0098] The knocking mechanism 2 is configured into multiple groups, and the multiple groups of knocking mechanisms 2 knock on different sides of the carbon block 6 respectively;

[0099] The detection system also in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com