Device and method for testing cast-rolled blank of aluminum foil for power battery

A power battery and testing device technology, applied in sorting and other directions, can solve the problems of unqualified batteries, waste of working time and work efficiency, and untargeted processing, etc., and achieve the effect of convenient separation and accurate detection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

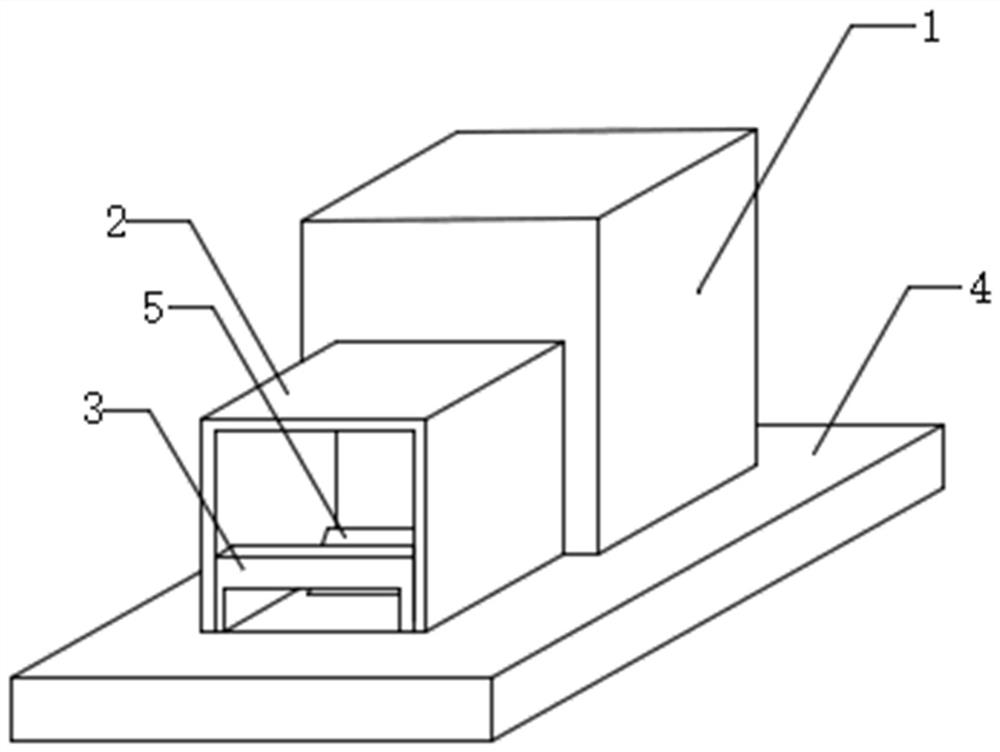

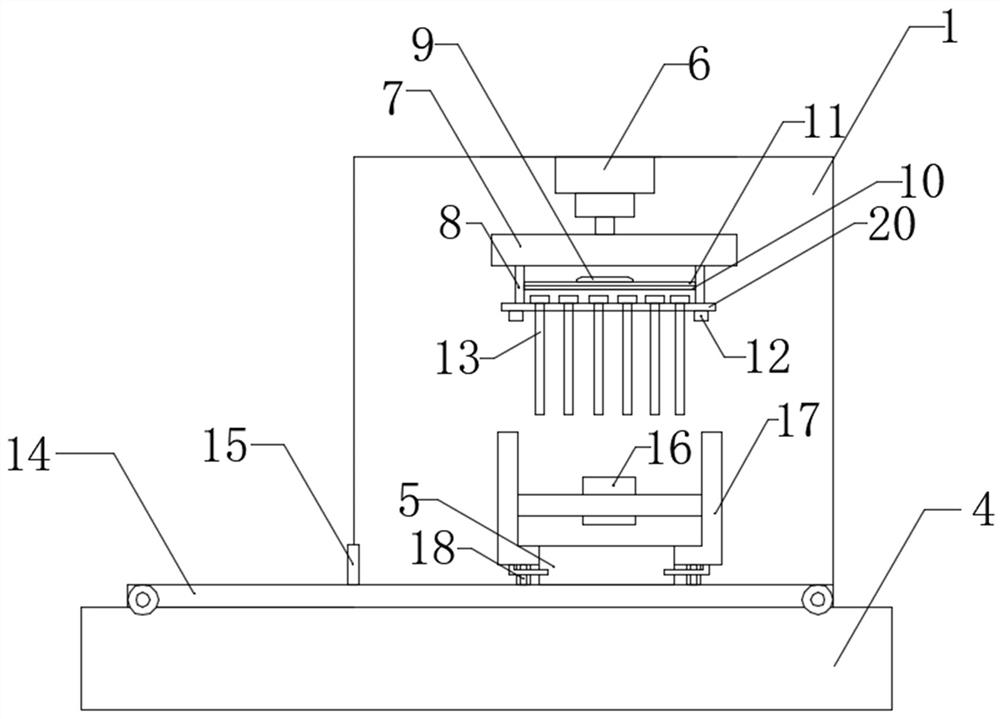

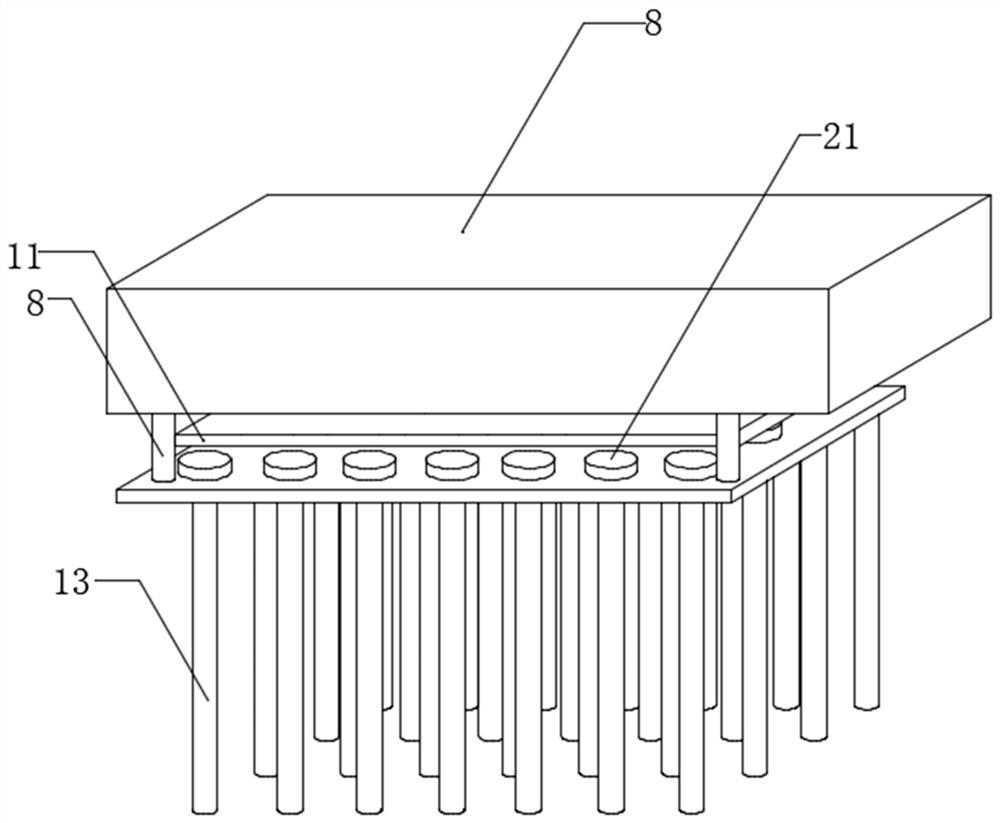

[0028] Such as Figure 1-5 As shown, a test device and method for casting and rolling blanks of aluminum foil for power batteries, including a detection box (1) and a sorting box (2), the bottom of the detection box (1) and the sorting box (2) is equipped with a bottom plate (4), the sorting box (2) is installed on one side of the detection box (1), the connection between the bottom plate (4) and the detection box (1) is installed with a conveyor belt (14), and one side of the detection box (1) A material inlet (15) is provided, a first push rod motor (6) is installed on the top of the detection box (1), a support plate (7) is installed on the bottom of the first push rod motor (6), and a support plate (7) is installed on the bottom of the first push rod motor (6). The four corners of the bottom end of ) are all equipped with connecting columns (8), the middle of the four connecting columns (8) is provided with a mounting plate (11), and the bottom end of the mounting plate (1...

Embodiment 2

[0034] Such as Figure 1-5 As shown, a test device and method for casting and rolling blanks of aluminum foil for power batteries, including a detection box (1) and a sorting box (2), the bottom of the detection box (1) and the sorting box (2) is equipped with a bottom plate (4), the sorting box (2) is installed on one side of the detection box (1), the connection between the bottom plate (4) and the detection box (1) is installed with a conveyor belt (14), and one side of the detection box (1) A material inlet (15) is provided, a first push rod motor (6) is installed on the top of the detection box (1), a support plate (7) is installed on the bottom of the first push rod motor (6), and a support plate (7) is installed on the bottom of the first push rod motor (6). The four corners of the bottom end of ) are all equipped with connecting columns (8), the middle of the four connecting columns (8) is provided with a mounting plate (11), and the bottom end of the mounting plate (1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com