Device and method for testing filtering performance of ventilation system of railway vehicle

A technology for filtering performance testing and ventilation system, which is applied in the field of rail vehicles and can solve problems such as inability to accurately measure the filtering performance of ventilation systems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

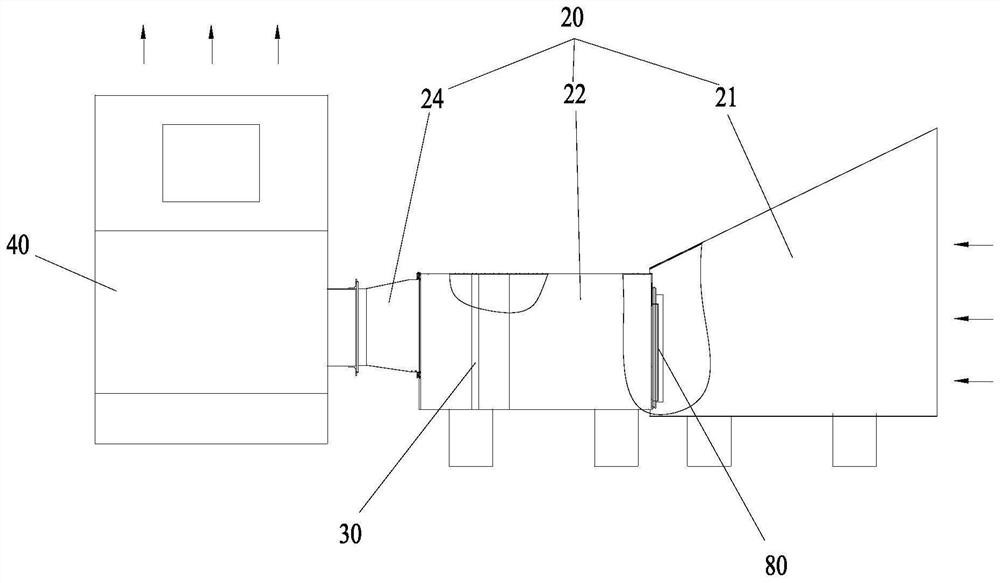

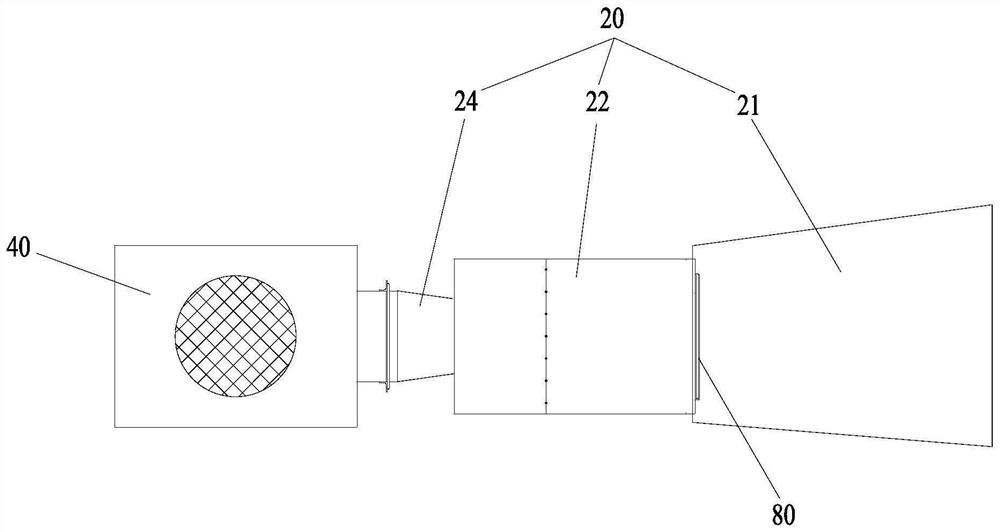

[0048] like Figure 1 to Figure 2 , Figure 9 and Figure 13 As shown, the ventilation system filtration performance testing device for rail vehicles includes a spray assembly 10, a test air duct assembly 20, a first filter 30, a cooling air simulation assembly 40, a wind resistance measurement assembly 60 and a weighing assembly. The spray assembly 10 is used for spraying the material to be filtered. The object to be tested 80 is arranged in the test air duct assembly 20 , and the spray assembly 10 communicates with the test air duct assembly 20 . The first filter 30 is disposed in the test air duct assembly 20 . The cooling air simulating assembly 40 communicates with the test air duct assembly 20 , and the cooling air generated by the cooling air simulating assembly 40 passes through the filter surface of the test piece 80 . The wind resistance measuring assembly 60 is used to measure the air volume and resistance of the DUT 80 . The weighing component is used to weigh...

Embodiment 2

[0075] Compared with the first embodiment, the composition structure of the filter performance testing device for the ventilation system of the rail vehicle is different in this embodiment.

[0076] Specifically, as Figure 5 to Figure 8 As shown, the ventilation system filtration performance testing apparatus for rail vehicles further includes a train wind simulation assembly 50 . The train wind simulation component 50 communicates with the test air duct component 20 , and the wind direction of the train wind generated by the train wind simulation component 50 is parallel to the filter surface of the test piece 80 . That is, the train wind generated by the train wind simulation assembly 50 blows in parallel from the surface of the test piece 80 during the test. The train wind simulation component 50 can simulate the train wind around the object to be tested 80 during the actual operation of the rail vehicle, so that the real wind environment of the object to be tested 80 can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com