Hoop type steel reinforced concrete beam column dry type joint structure

A joint structure and concrete technology, which is applied in the direction of building structure and construction, can solve the problems of anti-seismic performance, poor corrosion resistance, high cost, etc., to meet the requirements of sustainable development, optimize site installation and construction, and force transmission path clear effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below with reference to the accompanying drawings and embodiments.

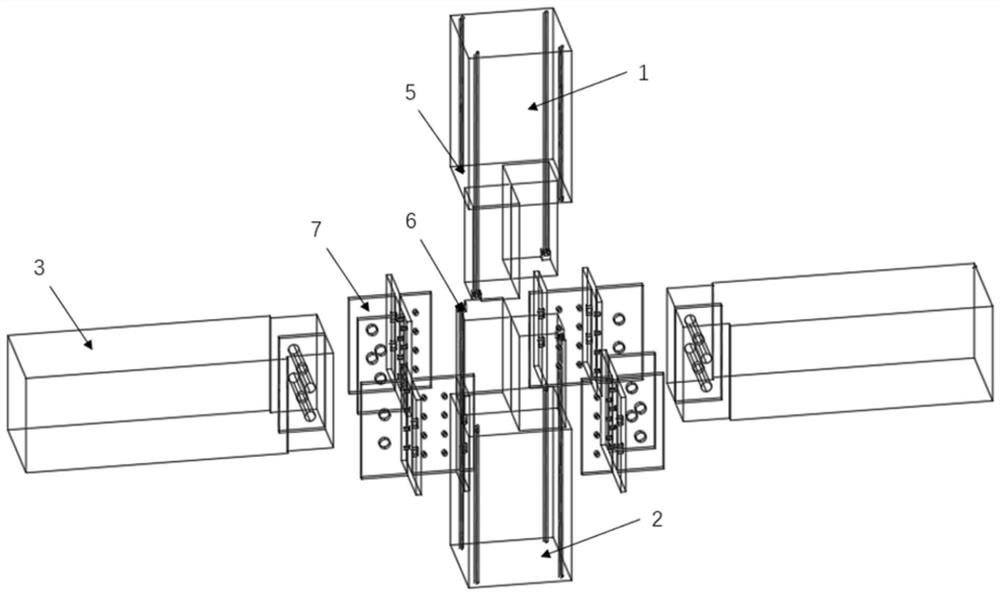

[0022] like figure 1 As shown, a hoop-type steel concrete beam-column dry joint structure includes a prefabricated upper column 1, a prefabricated lower column 2, a prefabricated beam 3, and a hoop-type node connector, the prefabricated upper column 1, the prefabricated lower column 2 mortise and tenon The connection forms a column, and the outer side of the column is fixedly connected to the four prefabricated beams 3 through a hoop-type node connector.

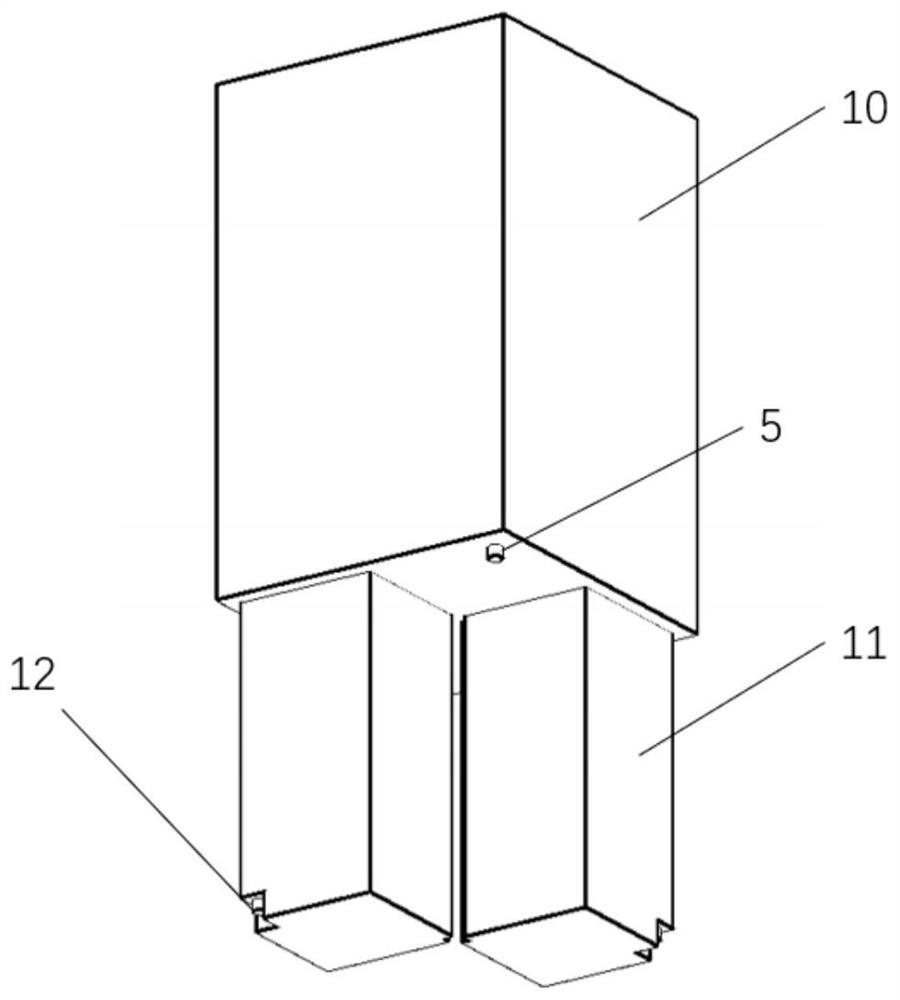

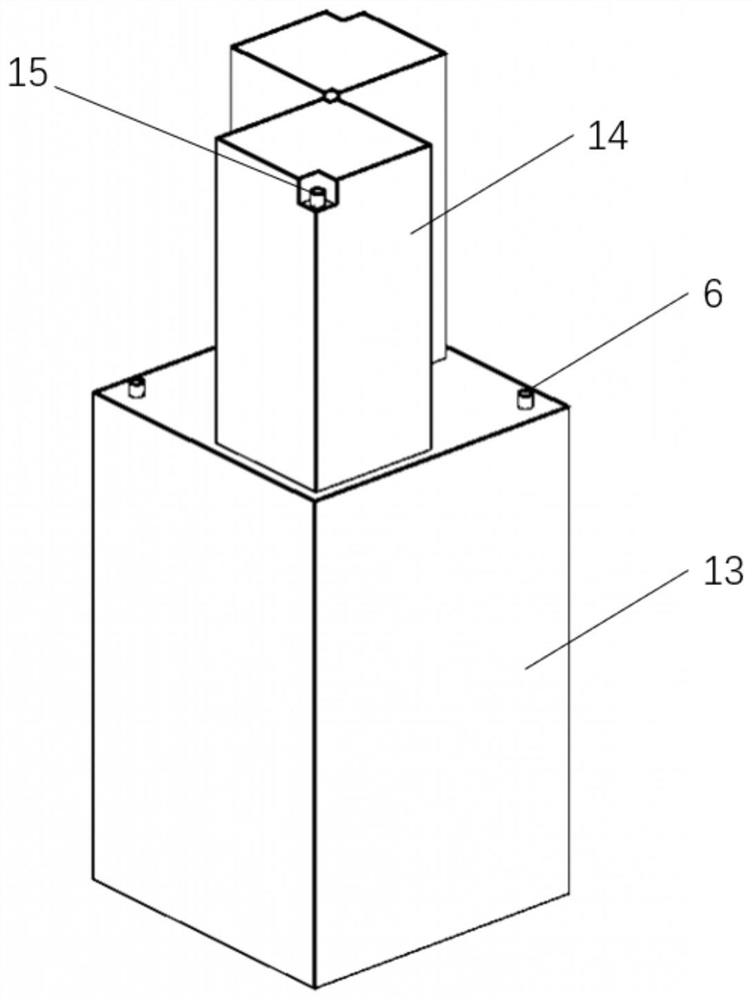

[0023] like figure 2 As shown, the prefabricated upper column 1 includes an upper column body 10 and an upper bump 11, the upper column body 10 has a square cross-section, and four first prefabricated steel bars 5 are vertically penetrated in four corners of the upper column body 10. , wherein the two first prefabricated steel bars 5 located on a diagonal line vertically pass through the lower surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com