Pipe joint component suitable for transverse bearing pipe curtain structure

A technology for carrying pipes and pipe joints, which is applied in basic structure engineering, construction, excavation, etc., can solve the problems of structural construction impact, insufficient supporting force, inconvenient filling of the gap between mother and child buckles, etc., and achieves the effect of firm support structure and good waterproof function.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

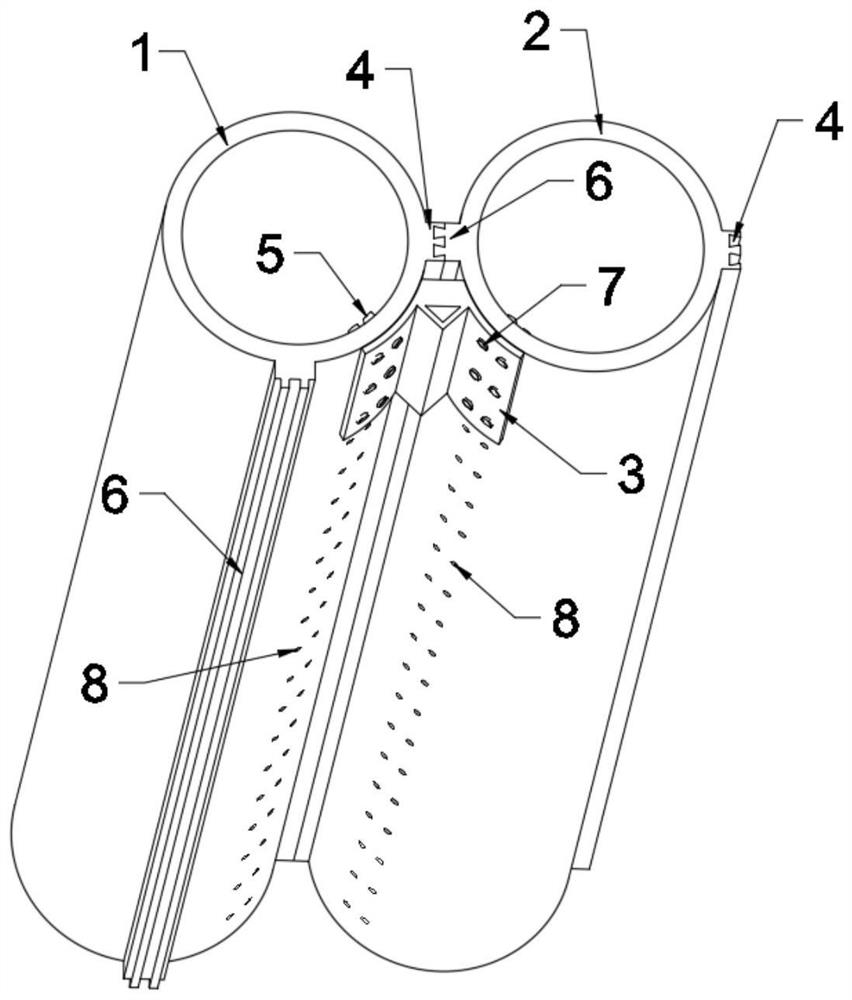

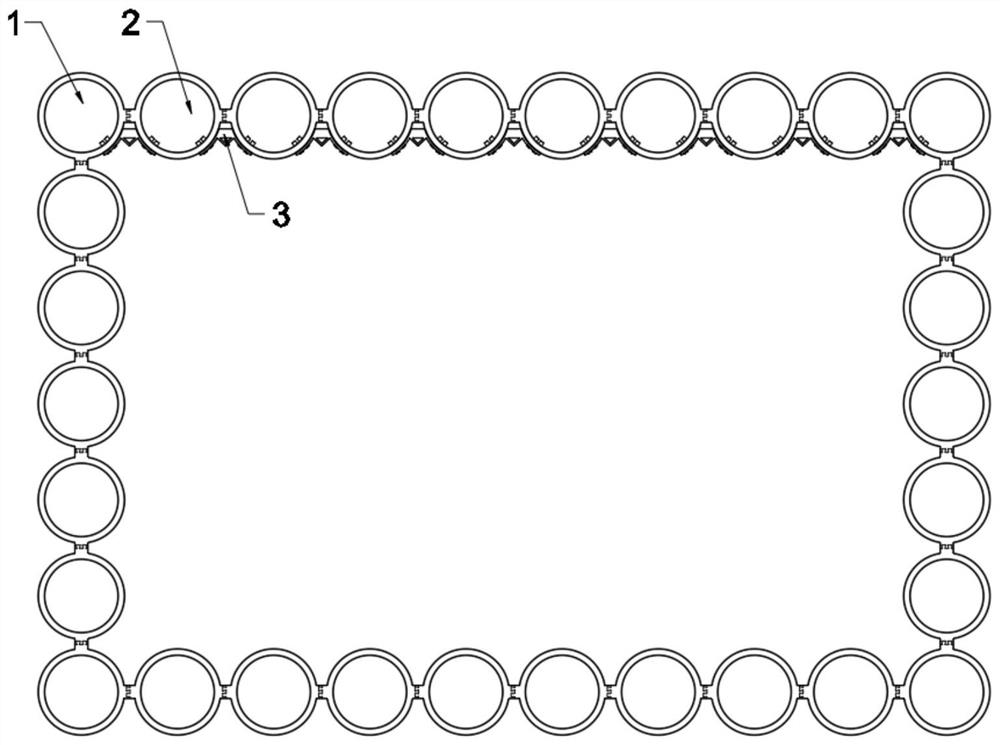

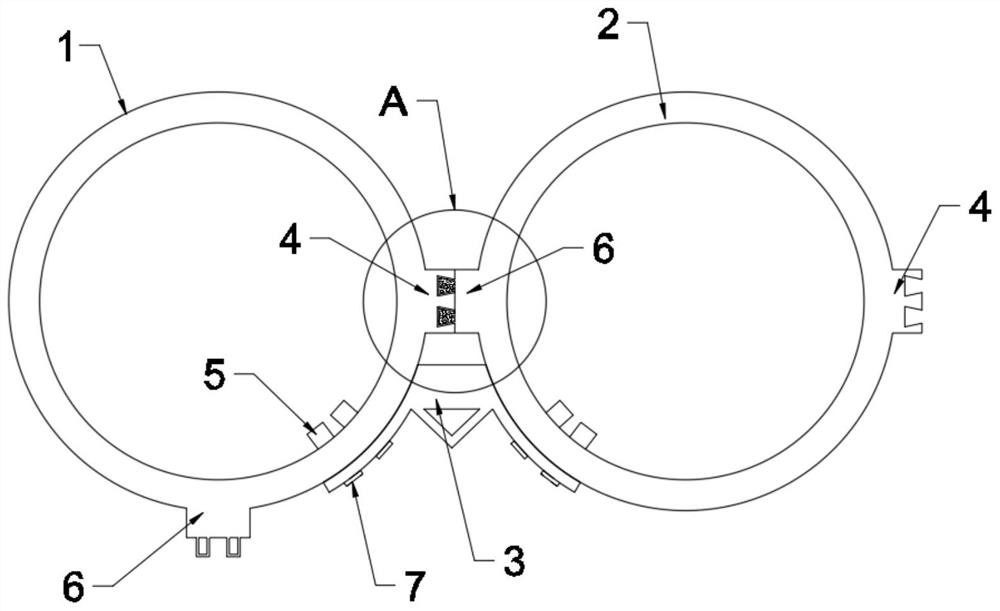

[0053] see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 and Figure 8 , a pipe section member suitable for lateral bearing tube curtain structure, including four working tube sections 1 and several pipe jacking tube sections 2; the four working tube sections 1 are located at the four corners of the lateral bearing tube curtain structure; The two adjacent working joints are connected by a plurality of pipe jacking joints;

[0054] Two mutually perpendicular socket members 4 and tenon members 6 are fixedly provided on the outer side of the working joint, and socket members 4 and tenon members 6 are also fixedly provided on both sides of the outer side of the jacking pipe section 2; There are at least two mortise grooves 41 with an isosceles trapezoid cross-section, and at least two frame-shaped tenons 61 with a rectangular cross-section are provided on the tenon member 6; the frame-shaped tenons 61 are formed of deformed metal plates, and...

Embodiment 2

[0061] see figure 1 , figure 2 , image 3 , Figure 9 , this embodiment adds the following scheme on the basis of Embodiment 1: between the working pipe section 1 and the pipe jacking pipe section 2 on the top layer of the lateral bearing pipe curtain structure, and between the pipe jacking pipe section 2 and the pipe jacking pipe section 2 There are pipe section gaskets 3 between them.

[0062] The pipe section gasket 3 includes side wings 31 symmetrically arranged on both sides, and the upper ends of the two side wings 31 are fixedly connected; There is a reserved bolt hole 8 at the bottom left or below, and the working pipe section 1 and the jacking pipe section 2 are located inside the bolt reserved hole 8 with a pre-embedded threaded steel sleeve 5; 7 Connect to the pre-embedded threaded steel sleeve 5 through the reserved installation holes 32 and the reserved bolt holes 8, so that the pipe section gasket 3 is fixed between the working pipe section 1 and the pipe ja...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com