Method for improving sagging and slipping of automobile coating adhesive by adopting laponite

A coating and sagging technology, applied in the direction of coating, etc., can solve the problems of affecting moisture resistance, poor adhesion, and shedding of rubber materials, and achieve the effects of reducing moisture, increasing viscosity, and increasing viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Step 1: In parts by mass, add 30 parts of diisobutyl phthalate plasticizer, 30 parts of inorganic calcium carbonate filler, and 0.4 part of laponite XLS into the barrel of the mixer respectively, and mix and stir at a high speed for 30 minutes.

[0050] Step 2: On the basis of Step 1, in parts by mass, continue to add 2 parts of α-pinene terpene resin tackifier, and mix and stir at a high speed for 20 minutes.

[0051] Step 3: On the basis of Step 2, in parts by mass, continue to add 21 parts of PVC resin, and mix and stir at a high speed for 20 minutes.

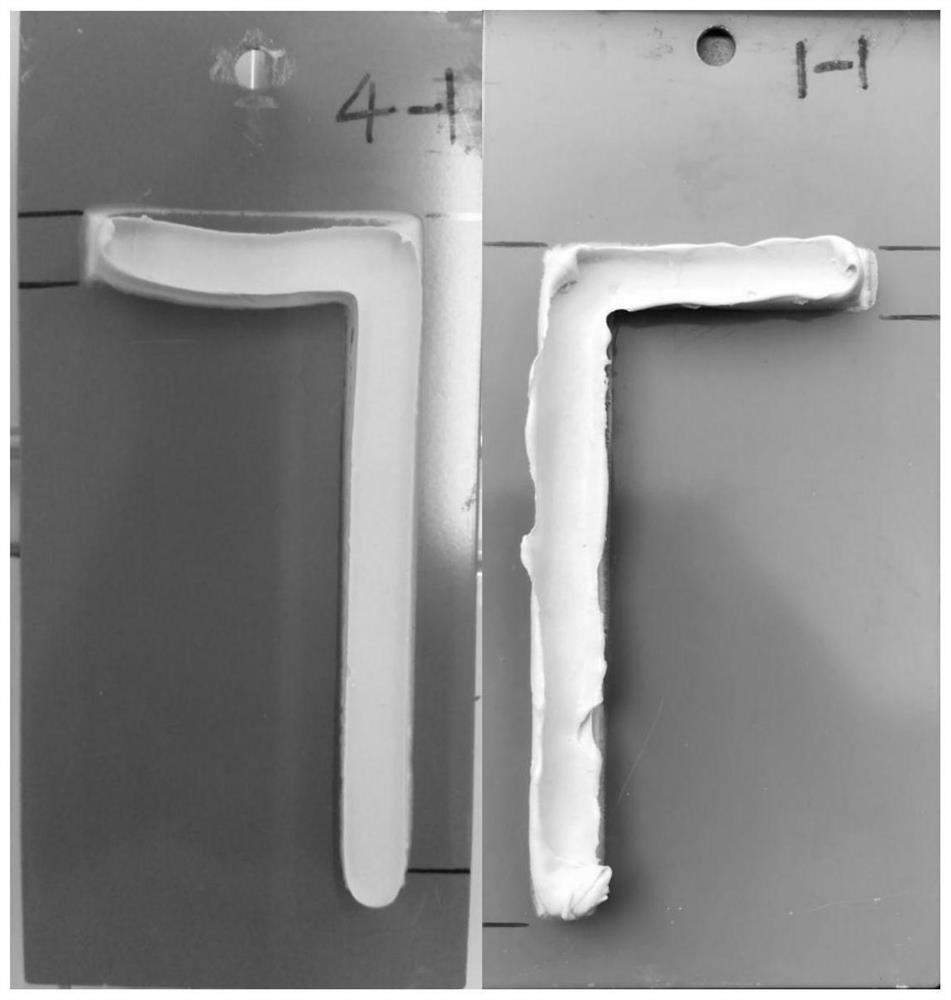

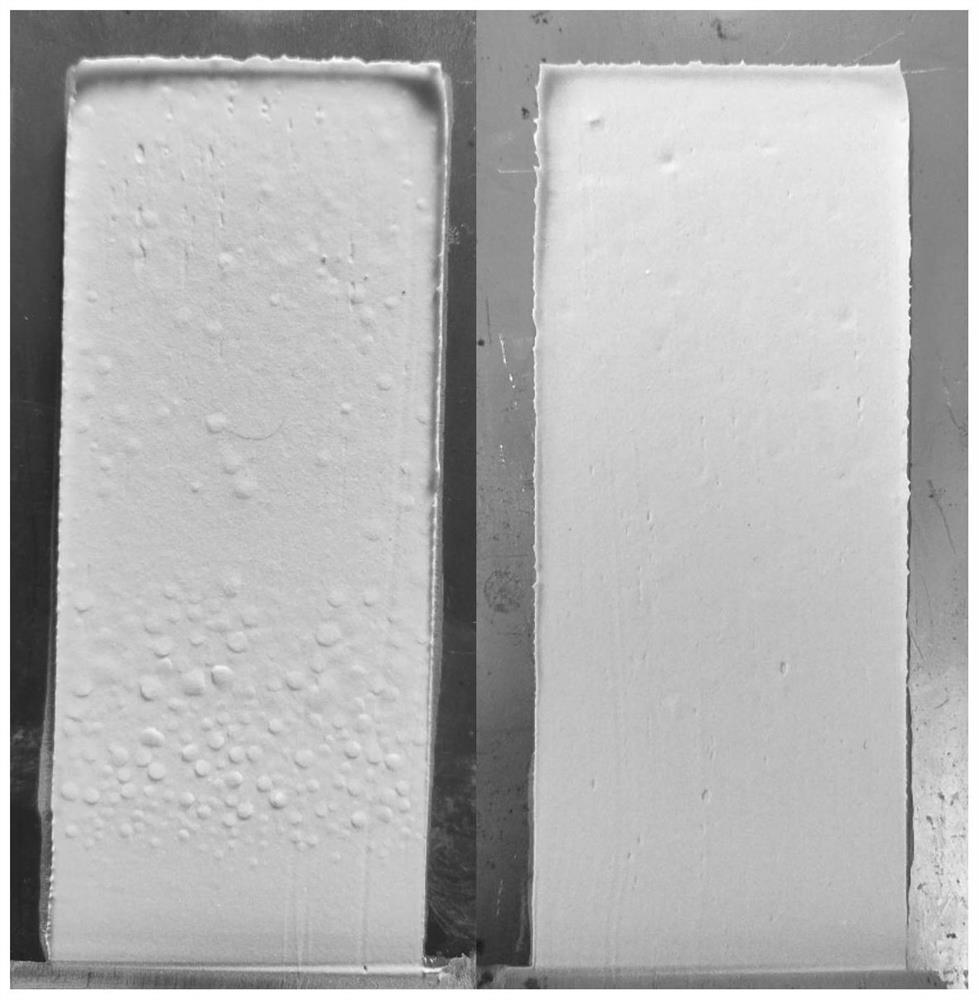

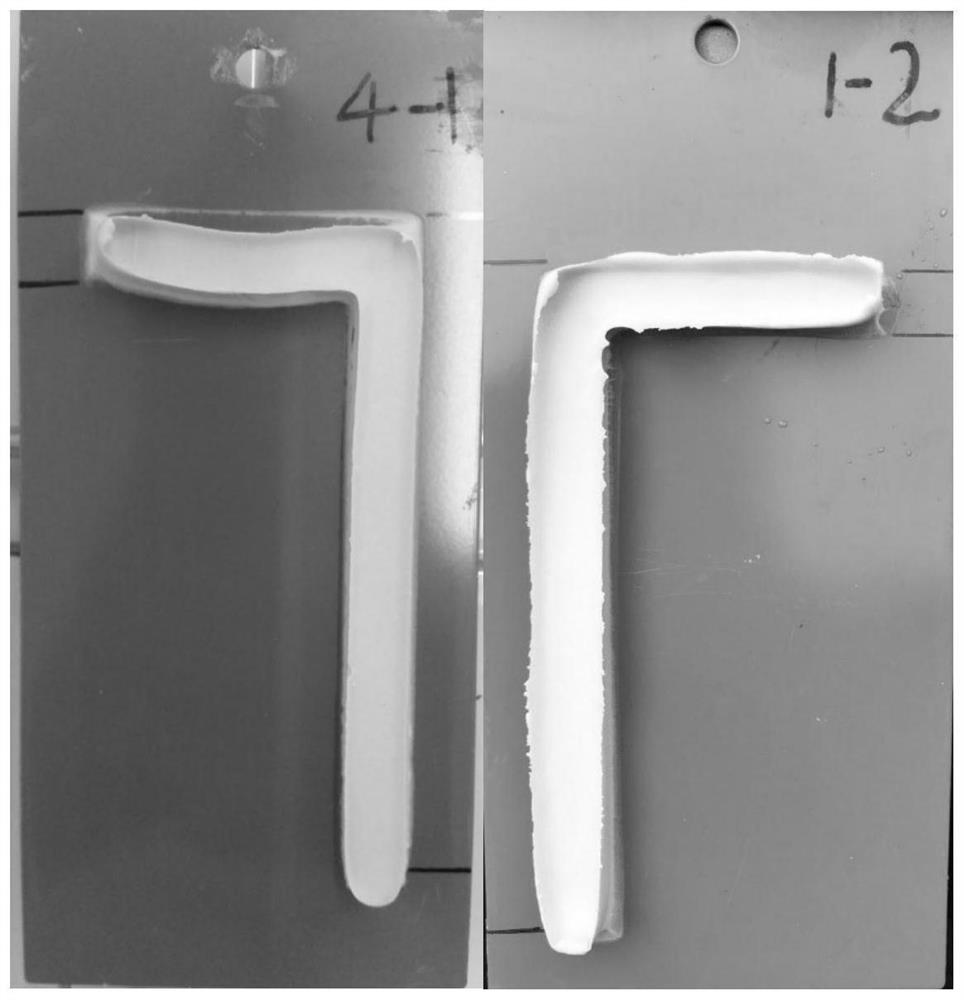

[0052] Step 4: On the basis of Step 3, vacuum defoaming the obtained PVC coating glue, and then lay the board. When laying the board, choose a hollow inverted "L"-shaped template, the outer length and width of the template is 120 × 70mm, and the inner inverted "L" The size of the type is from large to small: 100×90×50×40×10mm, and the thickness is 5mm.

[0053] Step 5: On the basis of step 4, first place the rubber c...

Embodiment 2

[0057] Step 1: In parts by mass, add 32 parts of diisobutyl phthalate plasticizer, 34 parts of inorganic calcium carbonate filler, and 0.8 part of laponite XLS into the barrel of the mixer respectively, and mix and stir at a high speed for 30 minutes.

[0058] Step 2: On the basis of step 1, in parts by mass, continue to add 1.7 parts of β-pinene terpene resin tackifier, and mix and stir at a high speed for 20 minutes.

[0059] Step 3: On the basis of Step 2, in parts by mass, continue to add 21 parts of PVC resin, and mix and stir at a high speed for 20 minutes.

[0060] Step 4: On the basis of step 3, vacuum degassing the obtained PVC coating glue, and then lay the board. When laying the board, choose a hollow inverted "L" type template, the outer length and width of the template is 120 × 70mm, and the inner inverted "L" The size of the type is from large to small: 100×90×50×40×10mm, and the thickness is 5mm.

[0061] Step 5: On the basis of step 4, first place the rubber c...

Embodiment 3

[0065] Step 1: In parts by mass, add 34 parts of diisobutyl phthalate plasticizer, 32 parts of inorganic calcium carbonate filler, and 1.2 parts of laponite XLS into the barrel of the mixer respectively, and mix and stir at a high speed for 30 minutes.

[0066] Step 2: On the basis of Step 1, in parts by mass, continue to add 2.1 parts of β-pinene terpene resin tackifier, and mix and stir at a high speed for 20 minutes.

[0067] Step 3: On the basis of Step 2, in parts by mass, continue to add 23 parts of PVC resin, and mix and stir at a high speed for 20 minutes.

[0068] Step 4: On the basis of Step 3, vacuum defoaming the obtained PVC coating glue, and then lay the board. When laying the board, choose a hollow inverted "L"-shaped template, the outer length and width of the template is 120 × 70mm, and the inner inverted "L" The size of the type is from large to small: 100×90×50×40×10mm, and the thickness is 5mm.

[0069] Step 5: On the basis of step 4, first place the rubbe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com