High-brightness black nylon material as well as preparation method and application thereof

A technology of nylon and bright black, which is applied in the field of high-gloss black nylon material and its preparation, which can solve the problems of large content of glass beads and poor appearance of high-gloss black materials, and achieve the effect that it is not easy to agglomerate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

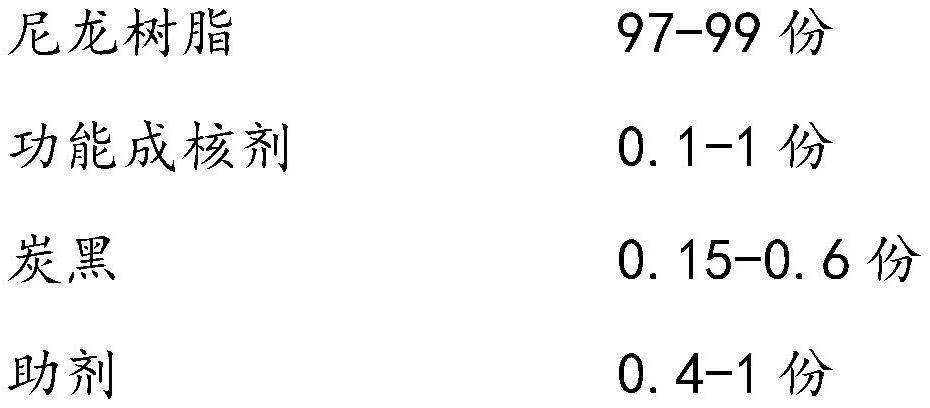

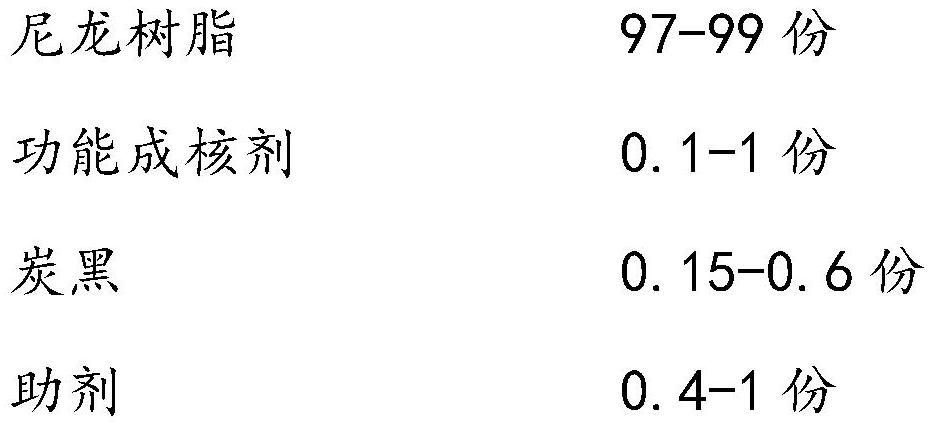

Method used

Image

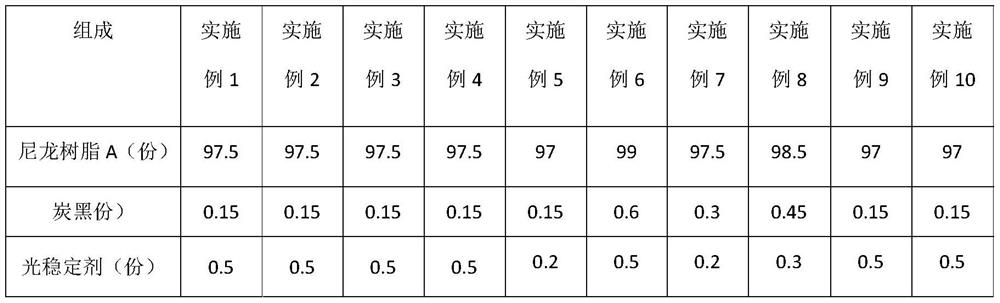

Examples

Embodiment 11

[0069] The high-brightness black composite nylon material of Example 8 is used to make a sample plate, and the performance test is carried out. The results are: the blackness L value is 24, the appearance has no pitting, the performance level of resistance to 60% ethanol solvent is 5 poles, and the performance of anti-snow melting agent is 5. The level is level 5. It can be shown that the high-gloss black nylon material provided by the present invention can be suitable for preparing vehicle interior parts with high requirements on appearance, solvent resistance and other properties.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com