Core-spun yarn body separation and impurity removal device

A core-spun yarn and thread body technology, which is applied in the field of core-spun yarn body separation and impurity removal devices, can solve the problems of poor separation effect of stripped thread bodies, and achieve the effect of avoiding random flying and unstable transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

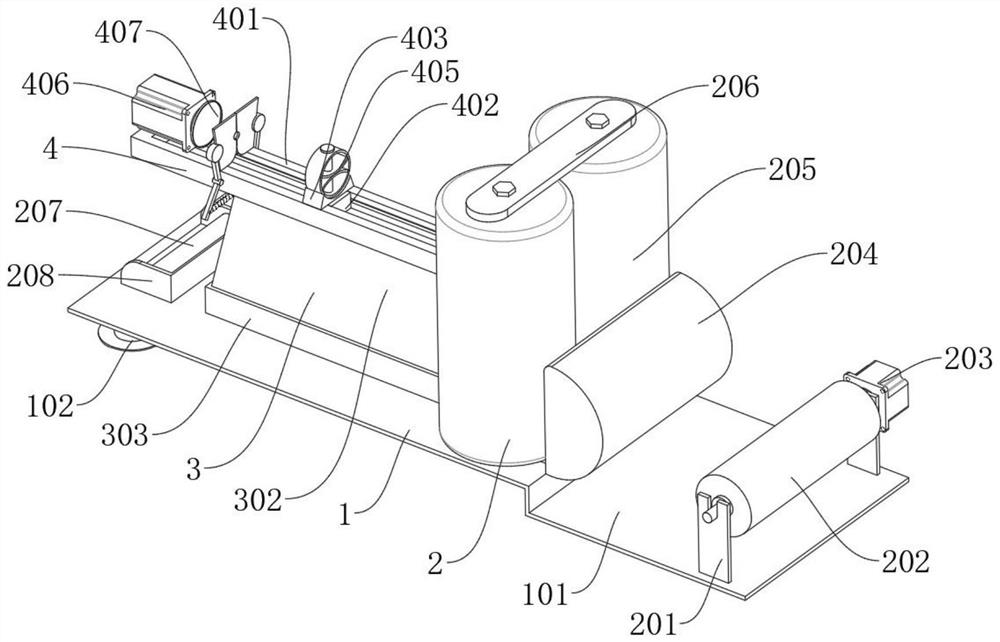

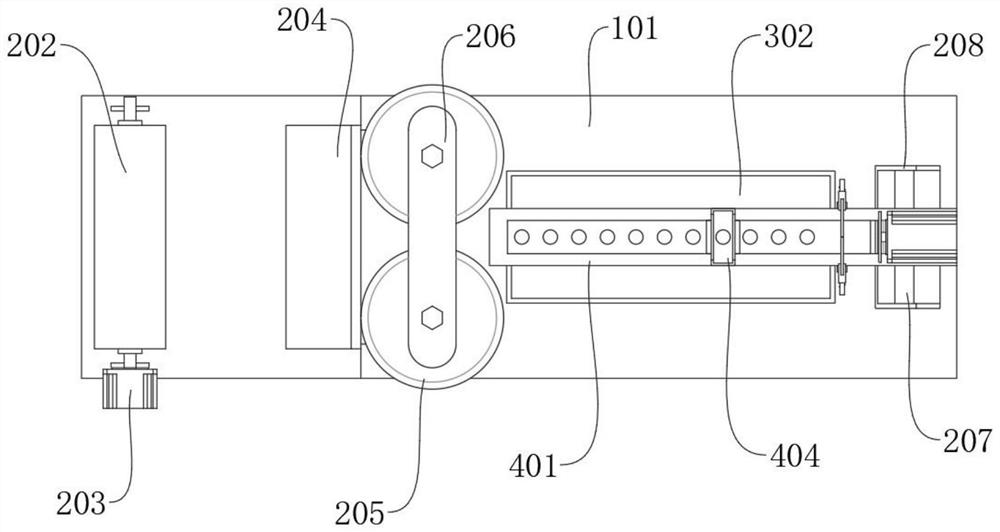

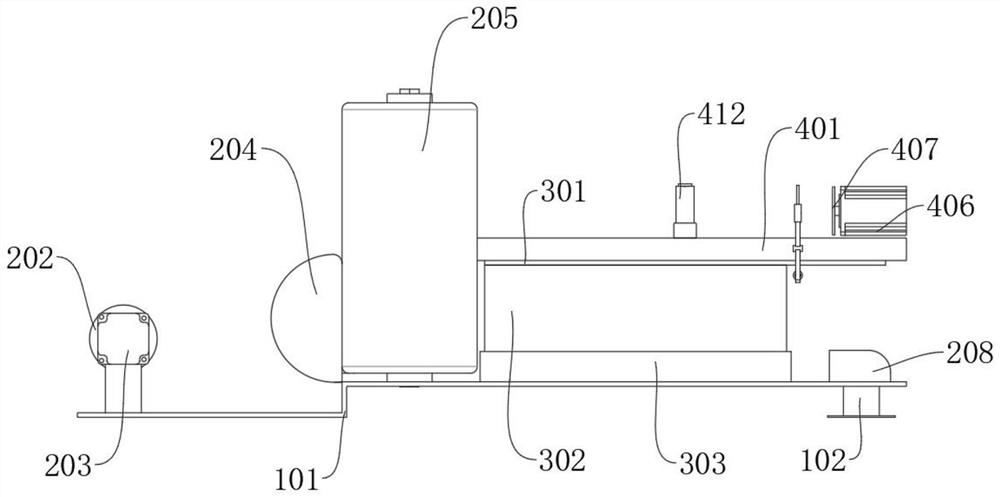

[0033] see Figure 1-Figure 5 The present invention provides a device for separating and removing impurities from a core-spun yarn body, which includes a bearing mechanism 1, a yarn feeding mechanism 2, and a short hair collecting mechanism 3. Both sides of the upper surface of the bearing mechanism 1 are connected with a yarn feeding mechanism 2 through bolts. A short-hair collection mechanism 3 is arranged between the mechanisms 2, and the short-hair collection mechanism 3 is connected with the bearing mechanism 1 by bolts, and also includes a separation mechanism 4 capable of separating the core spun yarn body from the outer fibers, and the separation mechanism 4 includes a slide rail 401. , slider 402, weak magnetic block 403, momentary cylinder 404, pressing piece 405, No. 3 motor 406, strong magnetic fit disc 407, movable arm 408, peeling knife 409, hydraulic rod 410, stabilizing spring 411, magnetic bearing cylinder frame 412 , the slide rail 401 is connected to the upp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com